技術資料 機械式過負荷保護機器 取扱

ミニキーパー MK 取扱

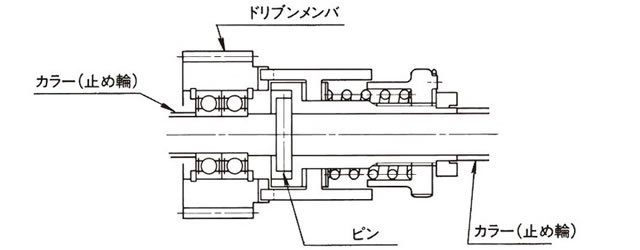

軸への取付け

- 1. ミニキーパーの軸穴径はすべて仕上っています。取付ける軸径の公差はh7またはh8を推奨します。

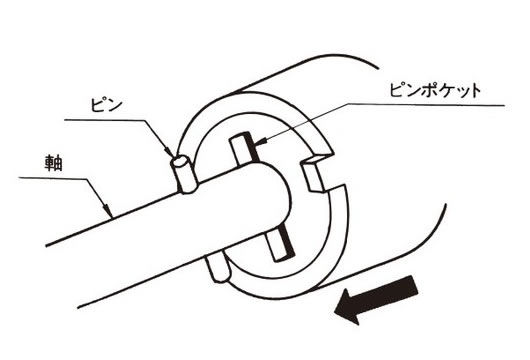

- 2. 軸との連結はボス端面のピンポケット(溝)を利用します。下図のように軸にピンをさし込み、ピンポケットにセットします。スキマは0.5mm程度です。

ピンの端面、側面とピンポケットの間は必ずスキマを取ってください。ピンの種類によってピン穴加工は異なります。

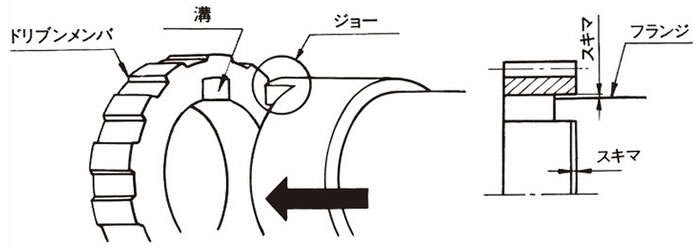

ドリブンメンバとの取付け

- 1. ドリブンメンバ(ギヤ、プーリなど)とのセットはフランジ部のジョーを使用します。ドリブンメンバ端面に溝を切り、ジョーをさし込むようにセットしてください。

この時ジョーを含むフランジ端面にスラスト荷重、ラジアル荷重が作用しないよう必ずスキマを設けてください。スキマは0.5mm程度です。

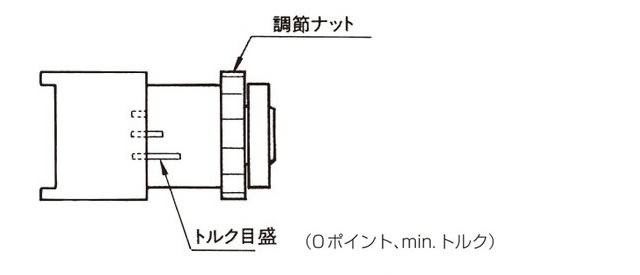

トルク設定

- 1. ミニキーパーはすべて0ポイント(min. トルク)の状態で出荷されています。

この時調節ナットの外周上にある目盛は下図の状態になっています。確認してください。

- 2. トルクの設定は調節ナットを締付けて行ってください。トルクカーブはこちらをご参照してください。

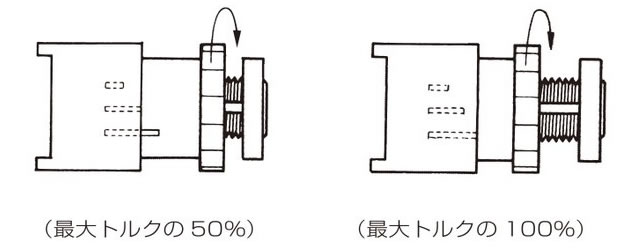

トルク目盛は下図のように設定トルクの目安としてください。設定トルクが適切であるかどうかは必ず実機で確認してください。

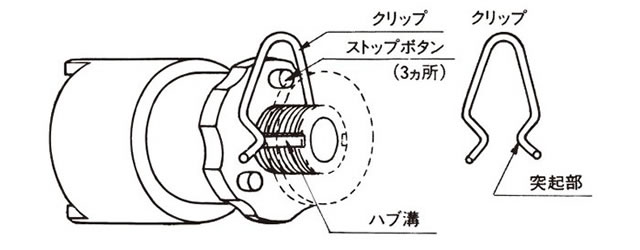

- 3. トルク設定終了後、調節ナットの回り止めを行います。回り止めは、付属の回り止めクリップを下図のように調節ナットとストップカラーの間にセットします。

回り止めクリップの突起部がボス溝(両側)に入っていることを必ず確認してください。回り止めクリップが調節ナットのストップボタン(凸部)にあたることで回り止めとなります。

注)1. マサツ面に水、油などが付着するとトルク異常が発生し、安定したスリップトルクが得られませんのでご注意ください。

注)2. ミニキーパーは周囲温度が約35℃以下を基準としています。この温度を越える場合は当社までご連絡ください。

取付例