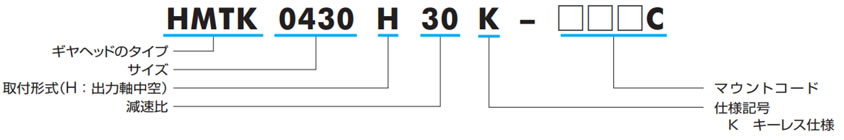

技術資料 減速機 サーボモータ用減速機TERVO 技術データ

中空軸タイプキーレス仕様

ハイポイドギヤヘッド HMTKタイプ

パワーロック付専用中空軸で、キーレス締結を可能とし、中空軸形の機能をさらに発揮します。

取付け・取外し作業を容易にし、機械装置の部品点数削減、省スペース化が図れます。

特長

- ・被動軸のキー溝加工が不要、部品点数、取付作業工数が削減できます。

- ・キーが無いので位相合わせが不要で、減速機の取付け・取外し作業が容易になります。

- ・強固な摩擦締結なので、抜け止め、緩み対策が不要で被動軸とのバックラッシがありません。

- ・専用軸端カバーも用意しています(ハイポイドモートル:0.2~0.4kW、0.75kW-1/5~1/50のみ)。

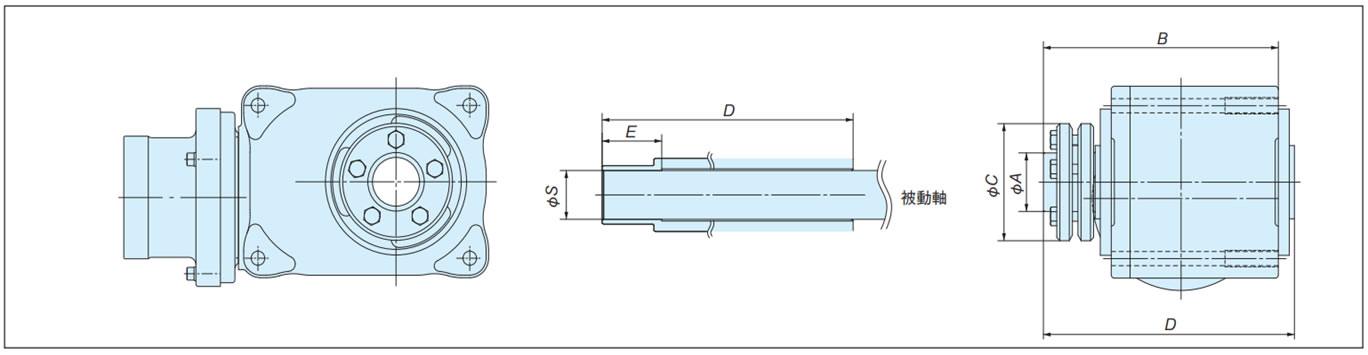

ハイポイドギヤヘッド仕様

| サイズ | 減速比 | ΦS | ΦA | ΦC | E | D | B | パワーロック形番 | ボルトサイズ | 締付トルクMA N・m {kgf・m} |

|---|---|---|---|---|---|---|---|---|---|---|

| HMTK02 | 1/5 ~ 1/60 | 20 | 30 | 60 | 31 | 122.5 | 118 | PL030X060SL | M5×18 | 4.9 {0.15} |

| 1/80 ~ 1/200 | 30 | 36 | 72 | 38 | 160 | 150 | PL036X072SL | M6×20 | 11.8 {1.2} | |

| HMTK04 | 1/5 ~ 1/50 | |||||||||

| 1/60 ~ 1/200 | 35 | 44 | 80 | 44 | 188 | 178 | PL044X080SL | M6×20 | 11.8 {1.2} | |

| HMTK075 | 1/5 ~ 1/50 | |||||||||

| 1/60 ~ 1/200 | 45 | 55 | 100 | 45 | 210 | 200 | PL055X100SL | M6×25 | 11.8 {1.2} | |

| HMTK15 | 1/5 ~ 1/80 |

- 注)ハイポイドモートル中空軸に締結する被動軸の寸法公差はΦS h6、仕上長さはE寸法以上、表面粗さは12S以下として、被動軸の仕上げ面がE寸法位置になるように設定してください。

- 注)0.2~0.4kW、0.75kWの1/5~1/50には専用の軸端カバーもご用意しています。