技術資料 減速機 DCブラシレスモータ 取扱

ここでは、DCブラシレスハイポイドモートル・ドライバに関する一般取扱について記載しています。

詳細につきましては、製品に添付しています取扱説明書をご参照ください。

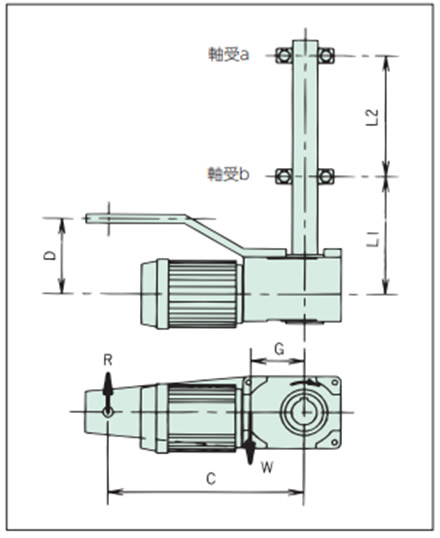

トルクアームの設計

標準トルクアームを用いたり、お客様でトルクアームを設計・製作される場合には、次の要領で各要素の強度を確認してください。

1. トルクアームおよび固定ボルトのチェック

トルクアーム反力Rにより確認してください。

R = T + W × G C

2. 軸受の選定

軸受反力A、Bにより確認してください。

A(軸受a) = L1 × (R - W) -D × R L2

B(軸受b) = (L1 + L2) × (R - W) - D × R L2

*出力トルクは左図回転方向時+、反対方向時は-となります。

- T:出力トルク N・m{kgf・m}

- W:減速機の自重 kg{kgf}

- R:トルクアーム反力 kg{kgf}

- G:被動軸中心と減速機重心間距離 m

- C:被動軸中心と回り止め間の距離 m

- D:減速機中心と回り止め間の距離 m

- L1:減速機中心と軸受b間の距離 m

- L2:軸受aと軸受b間の距離 m

オプショントルクアーム使用時の各寸法(概略値)

| 形番 | DCHM020-20H10~60 | DCHM040-30H10~50 | DCHM075-35H10~50 |

|---|---|---|---|

| G | 0.067m | 0.065m | 0.108m |