技術資料 減速機 マイタ・ベベルギヤボックス 選定

マイタギヤボックス選定例

選定例1

一般選定

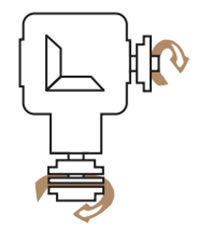

使用レイアウト

運転条件

- ・汎用モータ(15kW × 4P × 60Hz)をカップリング締結でモータ直結にてラテラル軸より入力。

- ・クロス軸側にはP.C.D.100mmのスプロケットを取付。

- ・負荷伝動kWは10kWにて運転。

- ・多少衝撃の伴う荷重で使用時間は10時間/日。起動停止 12回/時間の間欠運転。

- ・速比は1:1とする。

使用雰囲気

- ・屋内、常時30℃、通常雰囲気(塵埃などはなし)

オプション

- ・特になし(標準品にて対応)

(1)使用係数の決定

運転条件(多少衝撃の伴う荷重、10時間/日、起動停止 12回/時間)で、表1より使用係数 = 1.50となります。

(2)補正kWの決定

補正kW = 10kW(負荷伝動kW)× 1.50(使用係数)= 15kW よって補正kWは15kWとなります。

(3)サイズの決定

補正kW = 15kW、入力回転速度1750r/minを満足するサイズは、伝動能力表より、ED6Mが選定されます。

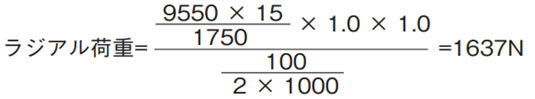

(4)ラジアル荷重の確認

(ラジアル荷重はクロス軸中央にかかることとします)

チェーン伝達にて表2よりO.H.L係数f = 1.0、ラジアル荷重が軸中央にかかることより作用位置係数Lf = 1となります。

ラジアル荷重の確認式および使用条件より、

ED6Mのクロス軸許容ラジアル荷重 = 2303N > 1637Nより許容値以内で使用可能となります。

(5)形番の決定

使用レイアウトの軸配置・回転関係・取付形式より、形番を決定します。

ED6M-1-R-Yが選定できます。※回転方向をご確認ください。

選定例2

ラインシャフトドライブ

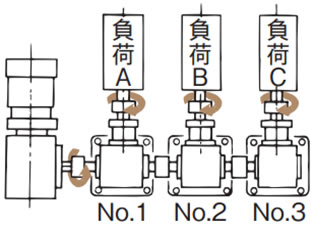

使用レイアウト

運転条件

- ・負荷A・B・Cはすべて245N・mの均一な負荷で使用時間は8時間/日

- ・入力回転速度は300r/minで速比はすべて1:1とする。

使用雰囲気

- ・屋内、常時30℃、通常雰囲気(塵埃などはなし)

オプション

- ・特になし(標準品にて対応可能)

※ラインシャフトドライブ選定時の注意事項

ラインシャフトドライブの場合は歯車にかかる負荷とラインシャフト(クロス軸)にかかる負荷が異なりますので、個々に分けて選定する必要があります。

クロス軸のみの許容ねじり伝動能力(クロス軸許容トルク)を参照ください。

(1)使用係数の決定

運転条件(均一な負荷、8時間/日)で表1より、使用係数 = 1.0となります。

(2)各マイタギヤボックスの選定

1. マイタギヤボックス No. 1

- ・歯車は負荷Aのみを運転します。→ 245N・m × 1.0 = 245N・m以上の伝動能力を必要とします。

- ・クロス軸は負荷A、B、Cを運転します。→ (245N・m + 245N・m + 245N・m) × 1.0 = 735N・m以上のクロス軸トルクを必要とします。

よって、伝動能力表(製品ページ参照)およびクロス軸許容トルクよりED10Mが選定されます。

[ED10M 伝動能力 513N・m > 245N・m、クロス軸許容トルク 891N・m > 735N・m]

2. マイタギヤボックス No. 2

- ・歯車は負荷Bのみ運転します。→ 245N・m × 1.0 = 245N・m以上の伝動能力を必要とします。

- ・クロス軸は負荷B、Cを運転します。→ (245N・m + 245N・m) × 1.0 = 490N・m以上のクロス軸トルクを必要とします。

よって、伝動能力表(製品ページ参照)およびクロス軸許容トルクよりED8Mが選定されます。

[ED8M 伝動能力 331N・m > 245N・m、クロス軸許容トルク 627N・m > 490N・m]

3. マイタギヤボックス No. 3

- ・歯車、クロス軸のいずれも負荷Cのみを運転します。→ 245N・m×1.0=245N・m以上の伝動能力・クロス軸トルクを必要とします。

よって、伝動能力表(製品ページ参照)およびクロス軸許容トルクよりED8Mが選定されます。

[ED8M 伝動能力 331N・m > 245N・m、クロス軸許容トルク 627N・m > 245N・m]

(3)形式の決定

使用レイアウトの軸配置・回転関係・取付形式より、形番を決定します。

No.1 ED10M-1-LR-O-Y

No.2 ED8M-1-LR-O-Y

No.3 ED8M-1-R-O-Yが選定できます。

※回転方向をご確認ください。