技術資料 小形コンベヤチェーン 取扱

フリーフローチェーン使用上の留意点

1. 倍速チェーン(スナップカバー付共通)

- (1)推奨コンベヤ機長は15m以下です。

- (2)エンプラローラの場合、油や水がかかるような雰囲気での使用は避けてください。(倍速機能を低下させるおそれがあります。)

- (3)パレットやワークを落下させたり、上から押さえ付けてチェーンに衝撃や圧力をかける使用方法は避けてください。

- (4)プラローラ付き倍速チェーンは、無潤滑でご使用ください。期待寿命を満足しない場合はラムダ仕様をご検討ください。

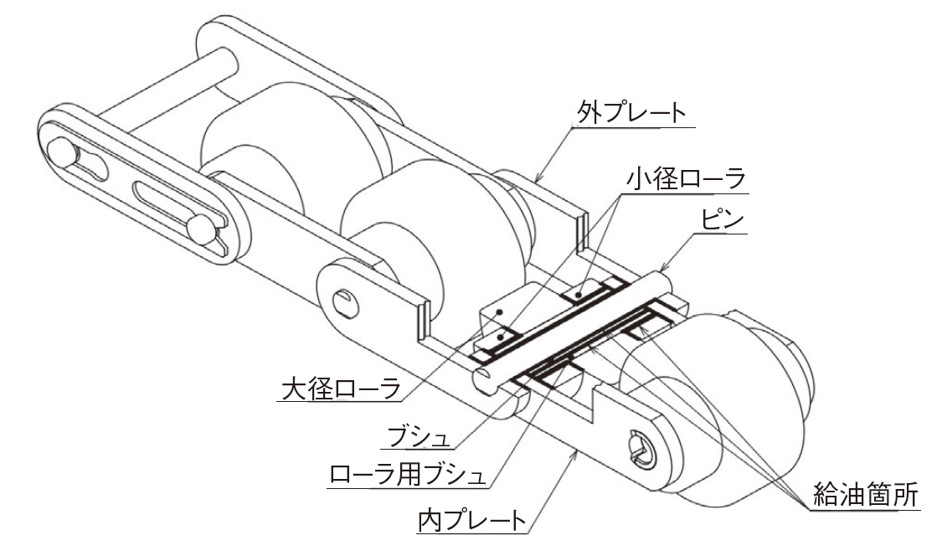

- (5)スチールローラには、摩擦係数の異常上昇防止のため、給油が必要です。

また、経年劣化により、スプロケット屈曲部や搬送部の大径、小径ローラ間で異音が発生した場合、ピン~ブシュ間、大径ローラ~小径ローラ間にSAE10~20の油を給油してください。給油方法はスプレー式給油器や刷毛塗り等で、給油が必要な箇所に油が届くように給油してください。なお、搬送物への油の転移によって問題が生じる場合は、ローラの外周に付着した油をふき取ってください。

ラムダ仕様はピン~ブシュ間での異音の発生を抑えられますので、給油ができない箇所や給油を嫌う箇所において使用をご検討ください。

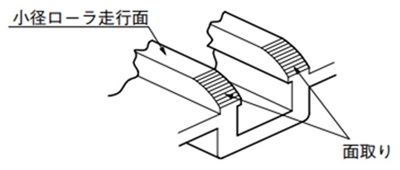

- (6)搬送側フレーム端部上面の加工

チェーンの小径ローラ走行面に面取りを施してください。

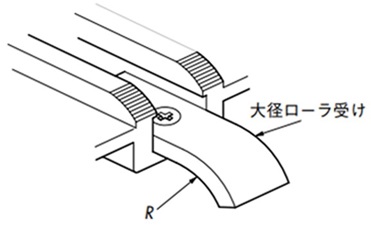

- (7)大径ローラ受け

従動側端部に「大径ローラ受け」を取付けることにより、面取部でのチェーン(大径ローラ)の沈込みを防止することができます。

-

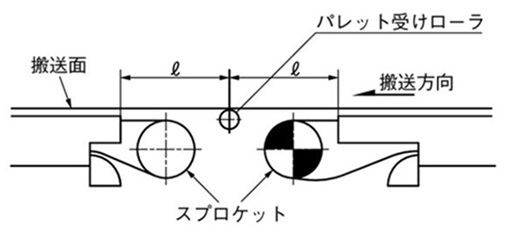

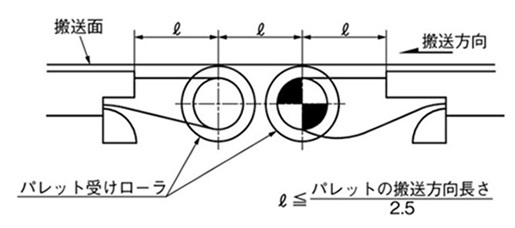

(8)コンベヤとコンベヤ間の処理(直線乗移り)

コンベヤの乗移り部には、パレットを安定した状態で搬送するために「パレット受けローラ」としてフリーローラやモータローラを取付けてください。

-

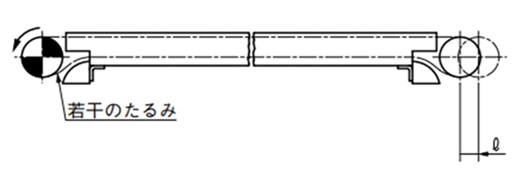

(9)テークアップ(1)

テークアップ量ℓ = チェーンピッチ × 2倍 + 余裕長さ

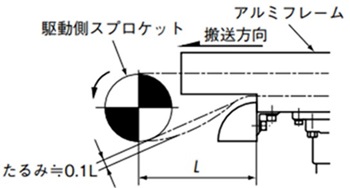

運転時に駆動側スプロケットの下部のチェーンに若干のたるみ(たるみはスパンの1割程度)ができるようにしてください。

たるみ量が大きくなった時はテークアップ調整するか、チェーンを切詰めてください。

チェーンのたるみ

単位:mm サイズ 通常たるみ 最大たるみ RF2030 25 75 RF2040 35 105 RF2050 40 120 RF2060 50 150 RF2080 65 190 こちらの倍速コンベヤ設計資料に基づいた場合のたるみです。

-

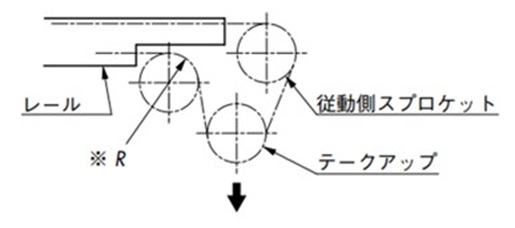

(10)テークアップ(2)

前後にコンベヤがあり、前ページのようなテークアップが設置できない場合は、下図を参考にしてください。

ただし、スナップカバー付倍速チェーンの場合は、※R寸法をリターンガイド(寸法図参照)のR寸法よりも大きくしてください。

-

(11)スプロケットと軸

駆動スプロケット...キー付で左右のスプロケットは位相合わせをしてください。

テークアップスプロケット...キーなし(フリー)で左右別々の軸とします。

他のスプロケット...キーなし(フリー)

⚠ 搬送物をチェーンに直接乗せると、搬送物に大径ローラの跡が付きますので注意してください。

*RF2030VRPUA、UB(ウレタンライニングローラ)は、搬送物をチェーンに直載せしても、比較的ローラの跡は付きにくい仕様です。

2. スナップカバー付倍速チェーン

- (1)スナップカバーは、エンプラ製のため丁寧に扱ってください。

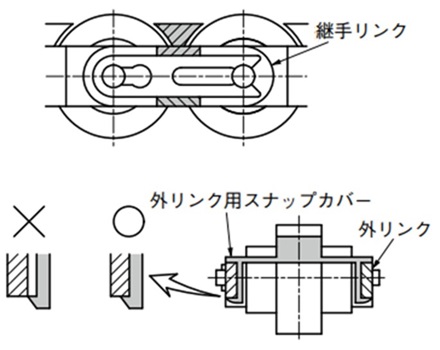

- (2)スナップカバーは、外リンク用と内リンク用の2種類がありますので間違って取付けないでください。(下図)

(スナップカバーは、チェーンに組込んで出荷しています。)

外リンク用スナップカバー

内リンク用スナップカバー

- (3)チェーンを連結の際は、専用の継手リンクを用いて連結後、外リンク用スナップカバーをプレートの切欠部に正しく取付けてください。(下図)

- (4)万一、取扱時にスナップカバーが破損した場合は、スナップカバーを新品と交換してください。