技術資料 小形コンベヤチェーン 取扱

潤滑

潤滑はチェーンを長期間ご使用いただくために必ず実施してください。特にチェーンに要求される性能が過酷になるほど、ますますその必要性が高まります。

- (1)給油の目的はチェーン各部の摩耗をおさえること、腐食(錆)を防止すること、所要動力を軽減することにあります。

- (2)給油は油が切れないように定期的に(1週間に1回程度)行ってください。給油方法は、下記潤滑油の滴下、またはハケ塗りとします。

- (3)給油箇所

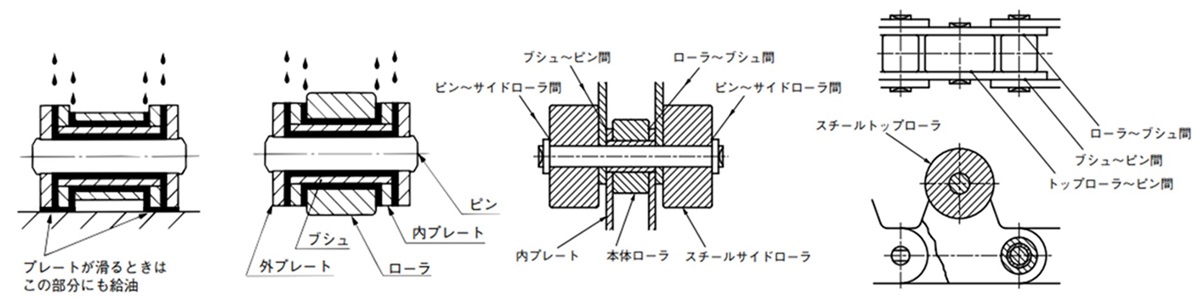

チェーンの摩耗伸びはピン~ブシュ間の摺動摩耗によって生じますから、この部分に給油する必要があります。また、レールとチェーン(プレート類)が摺動する部分にも給油してください(図26参照)。

RS形・バイピッチSローラ

バイピッチRローラ

サイドローラ付チェーン

トップローラ付チェーン

図26.給油箇所

表25 潤滑油 SAE番号

| 潤滑形式 | 滴下またはハケ塗り | |||

|---|---|---|---|---|

| チェーン番号 | 周囲温度 | |||

| -10℃ ~ 0℃ | 0℃ ~ 40℃ | 40℃ ~ 50℃ | 50℃ ~ 60℃ | |

| RS50, RF2050以下の小サイズのもの | SAE10W | SAE20 | SAE30 | SAE40 |

| RS60~100, RF2060~2100 | SAE20 | SAE30 | SAE40 | SAE50 |

| RS120, RF21200以上の大サイズのもの | SAE30 | SAE40 | SAE50 | |