技術資料 クラッチ 取扱

PBシリーズ 取扱注意

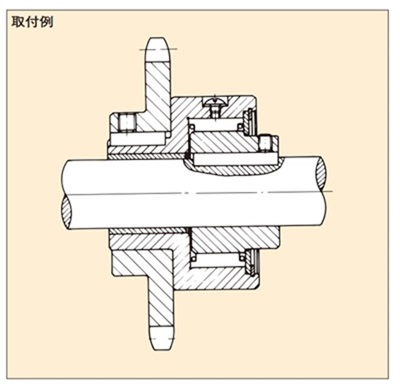

- 1. 内外輪の心出しは、外輪と軸の間の含油メタル軸受で行い、外輪に掛かるラジアル荷重も、このメタル軸受で受けます。したがって、軸の長さはメタル軸受が全面当る(外輪端部以上)長さにしてください。

- 2. 軸径公差

表の通りの寸法公差内に、軸を仕上げてください。

| PB3~PB8 |

PB10~PB14 |

+0

-0.013 |

+0

-0.016 |

- 3. スリーブに取付けるスプロケットなどの穴の寸法公差はH6、またはH7を推奨します。

- 4. 内外輪をそれぞれ左右の軸に直接取付けて、カップリングとして使用することはできません。この場合には、たわみ継手(ローラチェーンカップリングなど)と必ず併用してください。

- 5. 内輪のかみ合い方向には、右かみ合い(RH)、左かみ合い(LH)の2通りあります。ご注文の際は、前頁の矢印の方向から見た内輪のかみ合い方向を、必ずご指示ください。なお、取付・運転の際には、かみ合い方向の確認を必ず行ってください。

- 6. キーは、JIS B1301-1959(旧JIS)平行キー2種をご使用ください。なお、外輪のキー溝寸法は、JISで規定している軸径と、キー寸法の関係通りではありません。

- 7. 中高速域で使用する場合には、空転による発熱に注意せねばなりません。カムクラッチ外輪部の温度が70℃以上になるような場合には、十分な寿命が期待できません。別のシリーズを選定するか、使用条件を変更する必要があります。

- 8. インデキシングでご使用の場合は、オイル潤滑を推奨します。

- 9. カムクラッチには、スラスト荷重を掛けないでください。カムクラッチにスラスト荷重がかかる場合は、別途スラスト荷重を受けるものを設けてください。

- 10. 潤滑およびメンテナンスについてはこちらを参照ください。

- 11. 外輪に取付けるスプロケットなどの六角穴付き止ネジは締めすぎないように注意してください。