技術資料 クラッチ 取扱

MRシリーズ 取扱注意

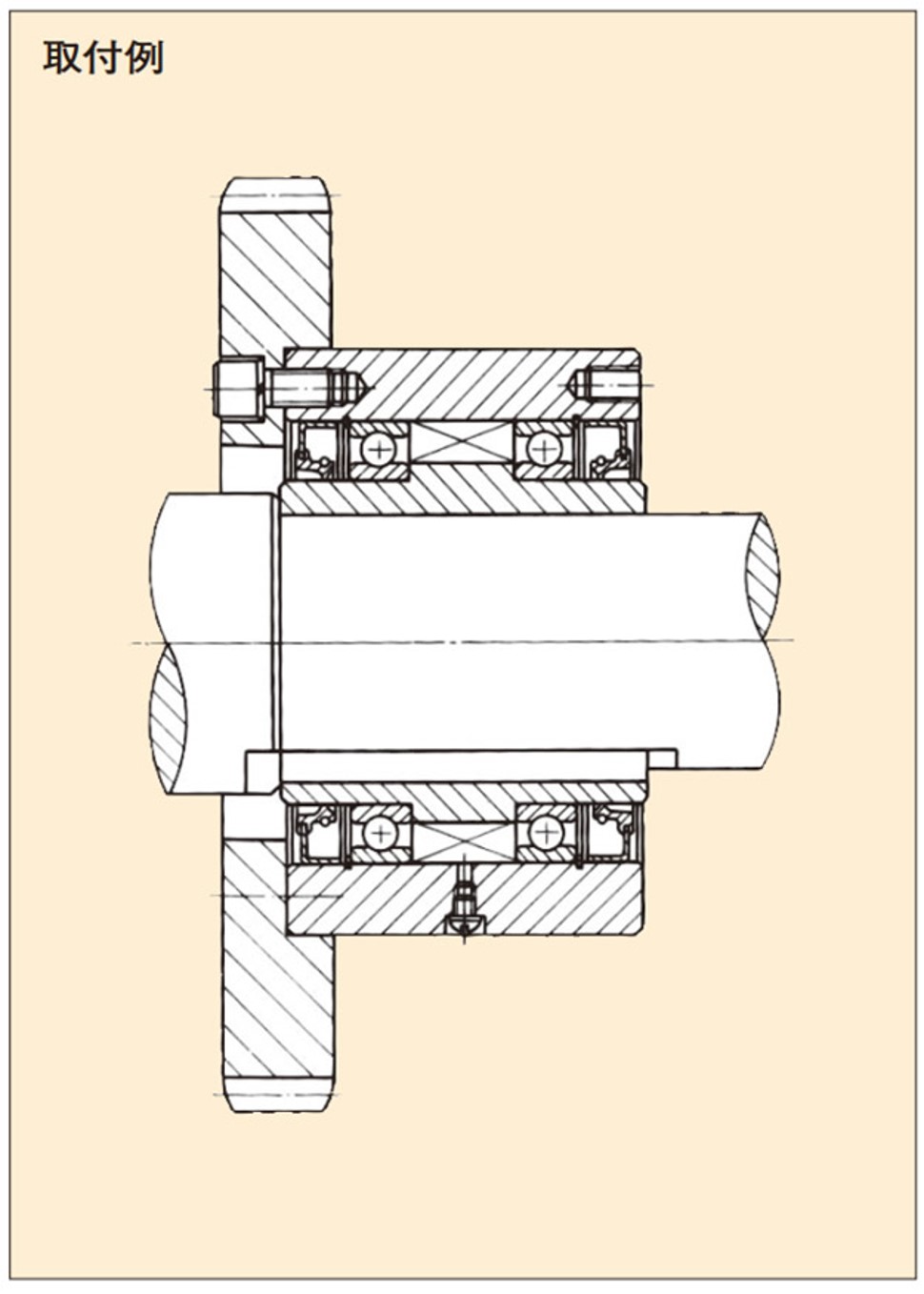

- 1. 外輪に取付けるスプロケットやギヤなどは、外輪の外周部B寸法(こちら)とインロにして、外輪端部のタップ穴に強度区分10.9以上の強度のボルトでしっかりと取付けてください。インロ部の公差はH6、またはH7を推奨します。

- 2. 軸径公差はh6、またはh7を推奨します。

- 3. MRシリーズのキーは、高さが特殊寸法のキーになっていますので、キーを付属しています。軸に対するキー溝深さはJIS通りで行ってください。

- 4. 空気(内圧)抜きの穴が、内輪キー溝底部に設けられていますので、キーの天井とキー溝底部は、空気(内圧)が逃げられるよう(0.1mm以上)すかしてください。

- 5. 軸へはめ込む際は、内輪端面に力を加えて取付けてください。外輪をたたくことは絶対に避けてください。

- 6. 許容最大トルク一杯、または、それに近いトルクでご使用の場合は、軸強度の確認を行った上、必要ならば調質、または焼入れした軸のご使用を推奨します。付属のキーは焼入れキーです。

- 7. カムクラッチにスラスト荷重がかかる場合は、別途スラスト荷重を受けるものを設けてください。

- 8. 連続運転をする場合は、強制潤滑を推奨します。方法については当社までご相談ください。

- 9. 出荷時に、潤滑油は封入されていませんので、ご使用前に推奨潤滑油を注入してください。

- 10. 潤滑およびメンテナンスについてはこちらを参照ください。