技術資料 クラッチ 取扱

MGシリーズ 取扱注意

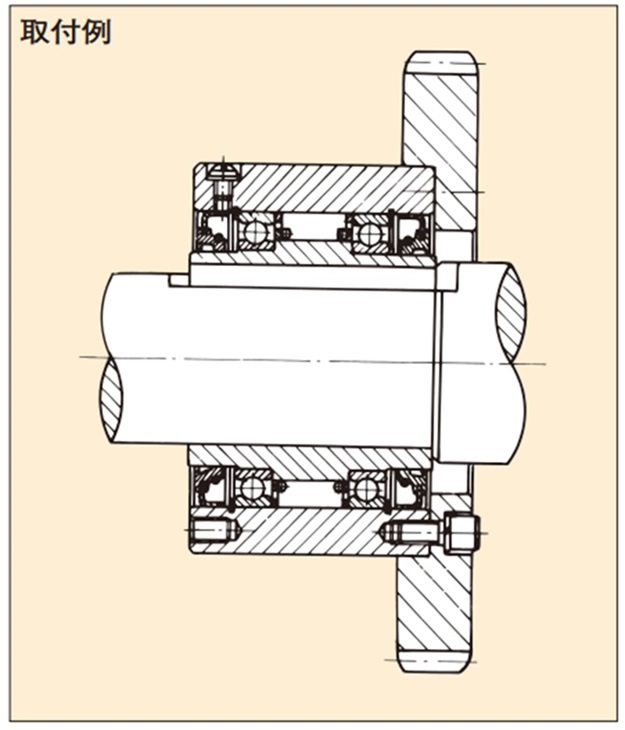

- 1. 外輪に取付けるスプロケットやギヤなどは、外輪の外周部B寸法(こちら)とインロにして、外輪端面のタップ穴に強度区分10.9以上の強度のボルトでしっかりと取付けてください。そのインロ部公差はH6、またはH7を推奨します。

- 2. 軸径公差はh6、またはh7を推奨します。

- 3. キーは必ず平行キーを使用し(MG750以上はキー付きで納入します)キーの天井を利かすことは絶対に避けてください。

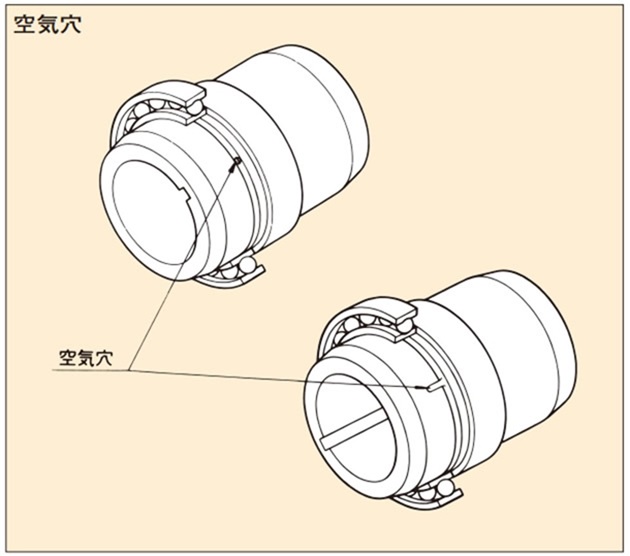

- 4. 空気(内圧)抜きの穴を内輪キー溝底部に設けていますので、キーの天井とキー溝底部は、空気(内圧)が逃げられるだけ(0.1mm以上)すかしてください。

- 5. キーは、JIS B1301-1959(旧JIS)平行キー2種をご使用ください。

(MG750以上は高さが特殊寸法のキーになっていますので、キーを付属しています。

なお、軸に対するキー溝深さはJIS通りにしてください。) 但し、軸径とキー寸法の関係はJIS通りでないものもあります。 - 6. 軸へはめ込む際は、内輪端面に力を加えて取付けてください。外輪をたたくことは絶対に避けてください。

- 7. 許容最大トルク一杯、またはそれに近いトルクでご使用の場合は、キーおよび軸は調質、または焼入れしたものの使用を推奨します。 (MG750以上に付属しているキーは焼入れキーです。) あわせて軸強度の確認も行ってください。

- 8. カムクラッチにスラスト荷重がかかる場合は、別途スラスト荷重を受けるものを設けてください。

- 9. 中高速域で使用されるときは、発熱に注意してください。カムクラッチ外輪部の温度が70℃以上になるような場合には、充分な寿命が期待できません。別のものを選定するか、またはオイルバス潤滑や強制潤滑の必要があります。連続空転の場合、最高空転回転速度の1/3以下が目安です。

- 10. 出荷時に、潤滑油は封入されていませんので、ご使用前に推奨潤滑油を注入してください。

- 11. 低速回転で使用される場合には、内圧調節用の空気穴からオイルが出て来ることがあります。200r/min以下でご使用になる場合は、空気穴無し仕様の見積をご用命ください。

- 12. 潤滑およびメンテナンスについてはこちらを参照ください。