技術資料 クラッチ 取扱

BBシリーズ 取扱注意

- 1. BBタイプは圧入により取付けを行い、適正なシメシロを与えることで軸受けとクラッチの機能が得られます。軸およびハウジングは必ず各製品ページに記載の推奨寸法に仕上げてください。シメシロが不足するとトルク伝達ができなくなる可能性があります。

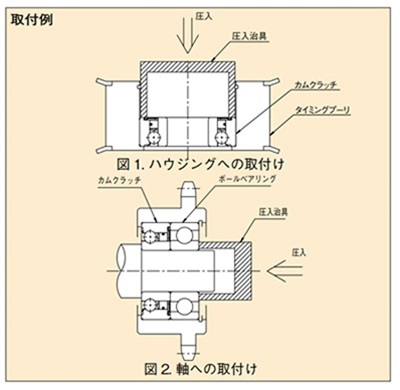

- 2. スプロケットやギヤ等のハウジングへの取付時には外輪に力を加えて圧入してください。その時もうひとつボールベアリングを入れてください。(図1参照)

- 3. 軸に取付けの際はハウジングに組付けられたをクラッチの内輪に荷重を加えながら圧入してください。(図2参照)

- 4. カムクラッチをハウジングと軸に同時圧入する際は、内輪または外輪のみに荷重をかけることは避けてください。また、ハンマー等でクラッチを叩くことは避けてください。

- 5. カムクラッチ内部に異物が混入するとカムクラッチの機能を損なうおそれがあります。取扱いにご注意いただくとともに、十分な防塵対策を行ってください。

- 6. あらかじめグリース(エクソンモービル・ジャパン(同)・ビーコン325J)が封入されていますので、そのままご使用いただけます。使用可能な周囲温度範囲は-30℃~80℃です。

- 7. オイル潤滑でご使用の場合は、グリースを洗い流してからご使用ください。オイル銘柄はこちらをご参照ください。油面は軸心以上に保ってください。

- 8. 極圧添加剤の入ったオイル、グリースはクラッチをスリップさせる原因になりますので、絶対に使用しないでください。

BBシリーズ 1K-Kタイプ(内輪キー溝付きタイプ) 取扱注意

BBシリーズ 2K-Kタイプ(内・外輪キー溝付きタイプ) 取扱注意

- 1. BB-1K-Kタイプは軸とのはめあいはすきまばめ、ハウジングとのはめあいはしまりばめとなっています。ハウジングとのシメシロによってトルク伝達をしますので、ハウジング寸法、肉厚寸法は必ず各製品ページに記載の推奨寸法に仕上げてください。シメシロが不足するとトルク伝達ができなくなる可能性があります。

- 2. BB-2K-Kタイプは軸とのはめあいはすきまばめ、ハウジングとのはめあいは中間バメとなっています。付属のキーを使って固定してください。

- 3. スプロケットやギヤ等のハウジングへの取付時、BB-1K-Kタイプは外輪に均等に力を加えて圧入し、BB-2K-Kタイプは付属のキーを使って固定してください。

また、ハンマー等でクラッチを叩くことは避けてください。その時もうひとつボールベアリングを入れてください。(図1参照)

- 4. 軸に取付けの際は付属の専用キーを使って固定してください。打込みキーなどでキーの天井を利かすことは絶対に避けてください。

- 5. キーおよびキー溝の規格はDIN6885.3です。ただし、BB25-1K-K, BB25-2K-Kの内輪側のキー溝深さは規格値より0.5mm浅くなっています。したがって軸側のキー溝を0.5mm深くしてください。BB40-1K-K、BB40-2K-Kの内輪側キーおよびキー溝の規格はDIN6885.1です。

- 6. カムクラッチ内部に異物が混入するとカムクラッチの機能を損なうおそれがあります。取扱いにご注意いただくとともに、十分な防塵対策を行ってください。

- 7. あらかじめグリース(エクソンモービル・ジャパン(同)・ビーコン325J)が封入されていますので、そのままご使用いただけます。使用可能な周囲温度範囲は-30℃~80℃です。

- 8. オイル潤滑でご使用の場合は、グリースを洗い流してからご使用ください。オイル銘柄はこちらをご参照ください。油面は軸心以上に保ってください。

- 9. 極圧添加剤の入ったオイル、グリースはクラッチをスリップさせる原因になりますので、絶対に使用しないでください。

BBシリーズ 2GDタイプ(両側ゴム接触シール付) 取扱注意

- 1. BB-2GDタイプは圧入により取付けを行い、適正なシメシロを与えることで軸受けとクラッチの機能が得られます。軸およびハウジングは必ず各製品ページに記載の推奨寸法に仕上げてください。シメシロが不足するとトルク伝達ができなくなる可能性があります。

- 2. スプロケットやギヤ等のハウジングへの取付時には外輪に力を加えて圧入してください。その時もうひとつボールベアリングを入れてください。(図1参照)

- 3. 軸に取付けの際はハウジング(クラッチ取付済)をクラッチ内輪に荷重を加えながら圧入してください。(図2参照)

- 4. カムクラッチをハウジングと軸に同時圧入する際は、内輪または外輪のみに荷重をかけることは避けてください。また、ハンマー等でクラッチを叩くことは避けてください。

- 5. あらかじめグリース(エクソンモービル・ジャパン(同)・ビーコン325J)が封入されていますので、そのままご使用いただけます。使用可能な周囲温度範囲は-30℃~80℃です。

BBシリーズ 2GD1K-Kタイプ(両側ゴム接触シール、内輪キー溝付) 取扱注意

- 1. 軸とのはめあいはすきまばめ、ハウジングとのはめあいはしまりばめとなっています。ハウジングとのシメシロによってトルク伝達をしますので、ハウジング寸法、肉厚寸法は必ず各製品ページに記載の推奨寸法に仕上げてください。シメシロが不足するとトルク伝達ができなくなる可能性があります。

- 2. スプロケットやギヤ等のハウジングへの取付け時には外輪に均等な力を加えて圧入してください。また、ハンマー等でクラッチを叩くことは避けてください。その時もうひとつボールベアリングを入れてください。(図1参照)

- 3. 軸に取付けの際は付属の専用キーを使って固定してください。打込みキーなどでキーの天井を利かすことは絶対に避けてください。

- 4. キーおよびキー溝の規格はDIN6885.3です。ただし、BB25-2GD1K-Kの内輪側のキー溝深さは規格値より0.5mm浅くなっています。したがって軸側のキー溝を0.5mm深くしてください。BB40-2GD1K-Kの内輪側キーおよびキー溝の規格はDIN6885.1です。

- 5. あらかじめグリース(エクソンモービル・ジャパン(同)・ビーコン325J)が封入されていますので、そのままご使用いただけます。使用可能な周囲温度範囲は-30℃~80℃です。