技術資料 大形コンベヤチェーン 取扱

7. 使用限界

コンベヤチェーンの各部品の使用限界について述べますので、定期的に各部の摩耗程度を点検してください。

この使用限界は、コンベヤチェーン自体の性能から決めた値です。コンベヤ本体の使用上から限界がある場合は、それを基準にしてください。

チェーンとスプロケットは同時に交換してください。

7.1 各部の使用限界

7.1.1 Rローラ・Fローラ

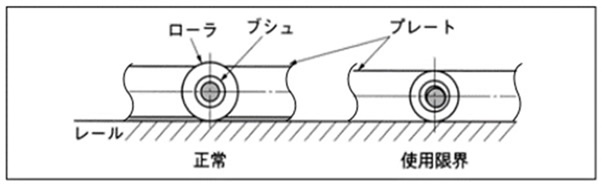

触軌面および、ブシュとの摺動部分の摩耗によって、プレートの下面がレールにあたり始める時をもって限界とします。

R・Fローラの限界

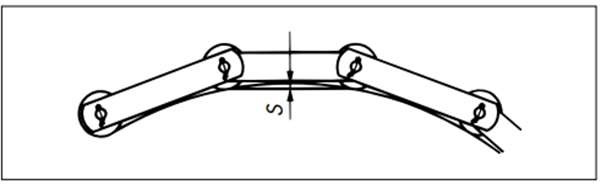

なお、レールに曲がり部分がある場合は、下図のようにSに相当する寸法だけ摩耗しろが少なくなりますので、ご注意ください。

摩耗しろの減少

7.1.2 S・M・Nローラ

摩耗によってローラ肉厚が40%になったとき。

7.1.3 ブシュ

摩耗によってブシュ肉厚が40%になったとき(外観からは点検できません)。

7.1.4 Cピン

摩耗によってピン径が85%になったとき(外観からは点検できません)

7.1.5 プレート板厚および幅の摩耗

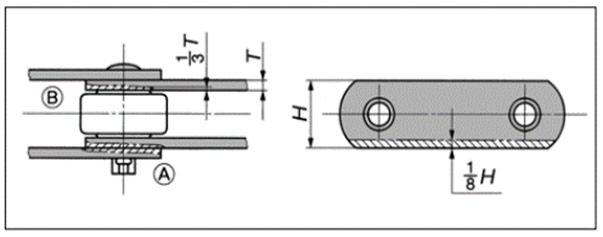

プレート相互間の摺動、およびローラ側面とプレート内面との摺動により、下図(左)のABのように摩耗が生じます。

摩耗量がプレートの正規の板厚の1/3を超えるときをもって寿命と考えます。

また、フローコンベヤのチェーンのようにプレートが直接搬送物、あるいは鉄板の上を滑る場合には、下図(右)のようにプレートの板幅Hが1/8H程度摩耗したときが寿命です。

プレートの摩耗

7.1.6 チェーンの摩耗伸び

チェーンはスプロケットに噛み合うときや、レールの曲り部で屈曲します。この時のブシュとピンの摺動による摩耗によってチェーンの全長が伸びます。

このチェーンの伸びの限度は、通常基準長さ(ピッチ×リンク数)の2%(ピッチ100mmなら1リンク当たり2mmの伸び)としています。

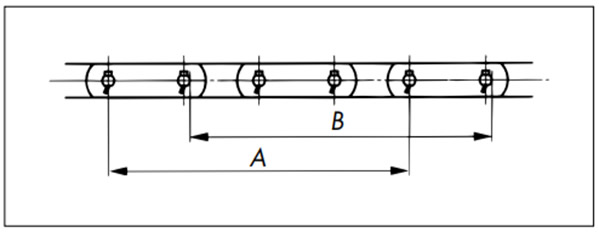

- 1) チェーン長さの測り方

張力のかかっている箇所で上図のようにできるだけ多くの偶数リンク(少なくとも4リンク以上)を測定してください。

測定位置は、(A)または(B)で測定してください。

(A)ピンの中心から中心まで

(B)ピンの一端から一端まで

- 2) チェーン伸び率(%)

A、Bいずれかの方法でチェーンの長さを測定し、基準長さと対比の上、チェーンの伸び率(%)を求めてください。

チェーン伸び = 測定寸法 - 基準長さ 基準長さ × 100(%)

7.1.7 スプロケットの歯面の摩耗、側面の摩耗

スプロケットの歯部が摩耗した状態でチェーンが噛み合うと、チェーンの摩耗が早くなる場合があります。

スプロケットもチェーンと同様に定期的に点検をしてください。

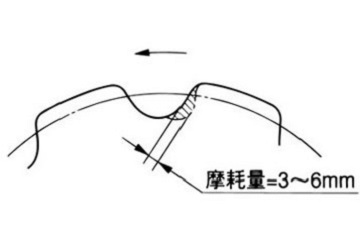

- 1) スプロケット歯面の摩耗限界は、下図を目安としてください。

歯面の摩耗

歯の側面の摩耗

- 2) 歯部が摩耗している場合は、取替えをおすすめします。歯底が摩耗している場合は、反転してそのまま使用することは避けてください。