技術資料 大形コンベヤチェーン チェーンの構造とローラの種類

大形コンベヤチェーンは、お客様の搬送物を搬送するために作られた、ISO規格に準じないメーカ独自の搬送用チェーンです。

そのため、チェーンメーカによってチェーン寸法が異なっている場合があります。

大形コンベヤチェーンの構造

チェーン本体はピン、ブシュ、ローラ、内・外プレートの5部品で構成されます。

基本的な構造はドライブチェーンと一緒です。

| 大形コンベヤチェーン構造の特長 | |

|---|---|

| ローラ | ・Rローラ、Fローラ、S/M/Nローラの3種類があります。 |

| 内・外プレート | ・フラット形状です。 |

| スプロケット | ・専用スプロケットが必要です。 |

ローラの種類と特長

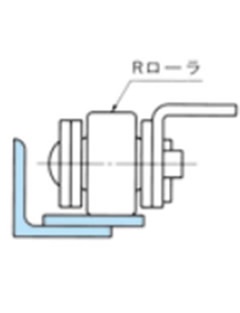

1. Rローラ

ローラ外径がプレート幅よりも大きいものです。

最も基本的で汎用性のある形式です。

ローラの負荷容量が大きく、摩擦抵抗が低い特長があります。

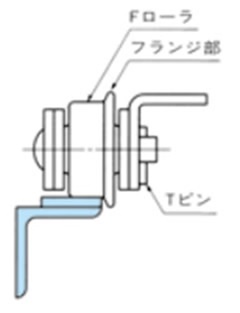

2. Fローラ

ローラにフランジを付けて転がりのガイドとしています。フランジ部はTピン側につきます。

簡単に横振れ防止ができます。通常のスラットコンベヤなどに適します。Kアタッチメントをご使用の際には、取付部がローラのフランジ部と接触することがありますのでご注意ください。

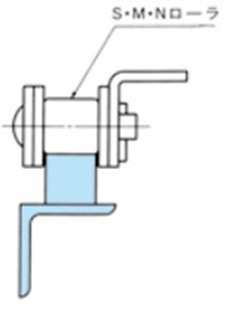

3. S, M, Nローラ

スプロケットの噛み合い時に衝撃や摩耗を緩和する効果があります。また、Rローラ・Fローラと比べ走行抵抗は大きくなりますが、軽量化が可能です。

- S:ローラ外径がプレート幅よりも小さい物

- M:ローラ外径がSローラより若干大きいもの

- N:ローラ外径をMローラと同一としてピン径を大きくした強度アップ形