技術資料 高速リフタ ジップチェーンリフタ ストローク制御

ストローク制御

リフタは『ストローク』内で使用してください。

(ストローク≧使用ストローク)

位置検出センサ仕様(ZSL1000)

| ストローク調整用リミットスイッチ | |

|---|---|

| メーカ | オムロン(株) |

| リミットスイッチ形式 | WLCA12-2-N(OMRON)相当品 |

| 電気容量 | AC250V 10A(cosΦ=0.4) DC5V 1mA(最小適用負荷) |

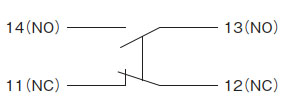

| 回路構成 |  |

| コネクタ(適合ケーブル外径) | SCS-10B(Φ8.5~Φ10.5)PF1/2 |

位置検出センサ仕様(ZSL0050)

| 下減速・下限停止 | |||

|---|---|---|---|

| メーカ | オムロン(株) | ||

| フォト・マイクロセンサ | EE-SPX303N | ||

| 入出力段 回路図 |

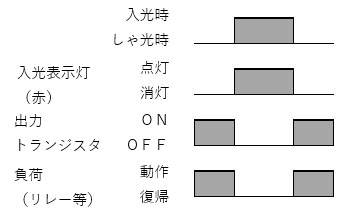

しゃ光時ON | タイム チャート |

|

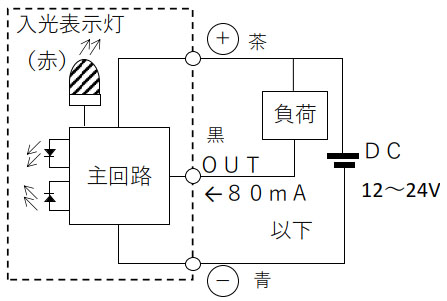

| 出力回路 |  |

||

| 電源・電圧 | DC12-24V±10% リップル(p-p)5%以下 | ||

| 接続方式 | EE-1010 2M付き | ||

| 上減速・上限停止 | ||||

|---|---|---|---|---|

| メーカ | オムロン(株) | |||

| フォト・マイクロセンサ | EE-SX672-WR | |||

| 入出力段 回路図 |

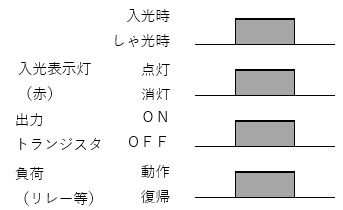

タイム チャート |

入光時ON |  |

接続端子 |

|

||||

| しゃ光時ON |

推奨  |

接続端子 | ||

|

||||

| 出力回路 |  |

|||

| 電源・電圧 | DC5-24V±10% リップル(p-p) 10%以下 | |||

| 接続方式 | コード引き出しタイプ | |||

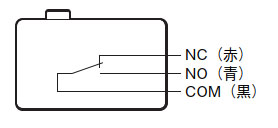

※1 しゃ光時ONの際にL端子を0Vと短絡しないでください。

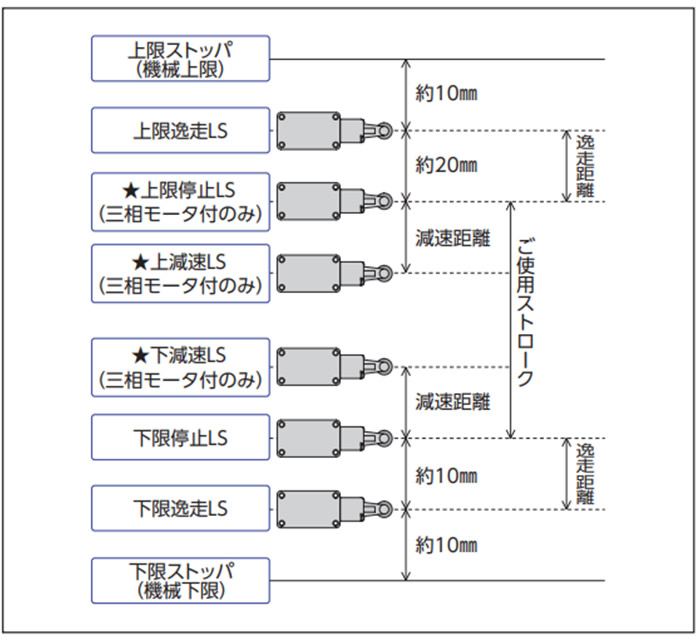

リミットスイッチ(LS)の配置(ZSL1000)

リミットスイッチ(LS)の配置(ZSL0050)

| 上限逸走・下限逸走 | ストローク調整用リミットスイッチ | |

|---|---|---|

| メーカ | オムロン(株) | |

| 小型スイッチ | D2VW-5L1-1M | |

| 接触仕様 |  |

|

| 定格電圧 | AC250V | 抵抗負荷:5A |

| AC125V | 抵抗負荷:5A | |

| DC30V | 抵抗負荷:5A | |

リミットスイッチの配置図の★印のセンサは、三相モータ付の場合のみ。 (サーボモータ付及びエンコーダ付モータの場合はこの位置のセンサはありません) 詳細は、納入図をご参照ください。

- ・ストロークの上下限は、上下停止リミットスイッチ(LS)で設定します。上下停止LSが有効に動作しない場合に備えて、上下限逸走LSを設けてあります。

- ・上下限逸走センサが動作した場合は、リフタを急制動で停止できるように直流別切りのブレーキ回路、およびシーケンス回路を外部で組み込んでください。

(リフタを最高速度以上で昇降させたり、ブレーキを交流切りにすると、リフタがストッパに衝突するため、絶対に避けてください。[ブレーキ制動時の遅れ時間が発生し、制動距離が伸びるため]

また、上限ストッパ、下限ストッパは機械的上限・下限で設定しています。絶対にさわらないでください。緩んでいたり、途中で止まっていると、天板フレームが下降時に接触し、機器の破損や重大な事故につながる恐れがあります。 - ※リフタ運転時の中間停止が必要な場合はロータリエンコーダ付き、もしくはサーボモータ付きをご使用ください。