Technical Data High-speed lifters Zip Master Handling

Operation/Inspection procedure

This section describes the general handling of ZIP MASTER.

For details, please refer to the instruction manual included with the product.

Operation

- ・Always use ZIP MASTER within the allowable load, the allowable overhung load, and the allowable lifting speed. Exceeding any of these ranges may damage the lifter.

- ・Under no circumstances should the lifter be used out of nominal stroke, even when operating with no load. Exceeding the nominal stroke range may damage the lifter. Do not subject the lifter to sudden impacts under any circumstances.

- ・Ensure that foreign substances such as dust and hot chips do not attach to or enter ZIP CHAIN or any other movable components or detection units. Such substances will accelerate wear in the unit and may lead to serious trouble such as chain fracture or damage to moving parts. Take appropriate measures to prevent foreign particles from entering the lifter. In addition, use a safety fence around the lifter to prevent entry into the space under the table frame.

- ・Be sure to design the sequence circuit so that the holding brake of the motor operates to prevent the load from dropping when operation is stopped.

- ・Never use the lifter with contact stop. Using the lifter with contact stop may cause serious damage to the lifter.

- ・Some areas of the lifter may become hot. Keep hands or any other part of the body from coming in contact with such areas.Failure to do so may result in burn injuries.

- ・Stop operation immediately if an error occurs.Failure to do so may result in electrical shock, injury or fire.

Inspection

1. Remove the cover

Remove the right cover when changing the positions of the upper and lower limit sensors and lubricating ZIP CHAIN. Remove the left cover when lubricating the guide.

Remove the mounting screw (cross-shaped recessed rounded head screws; M6 × 12) before removing the cover.

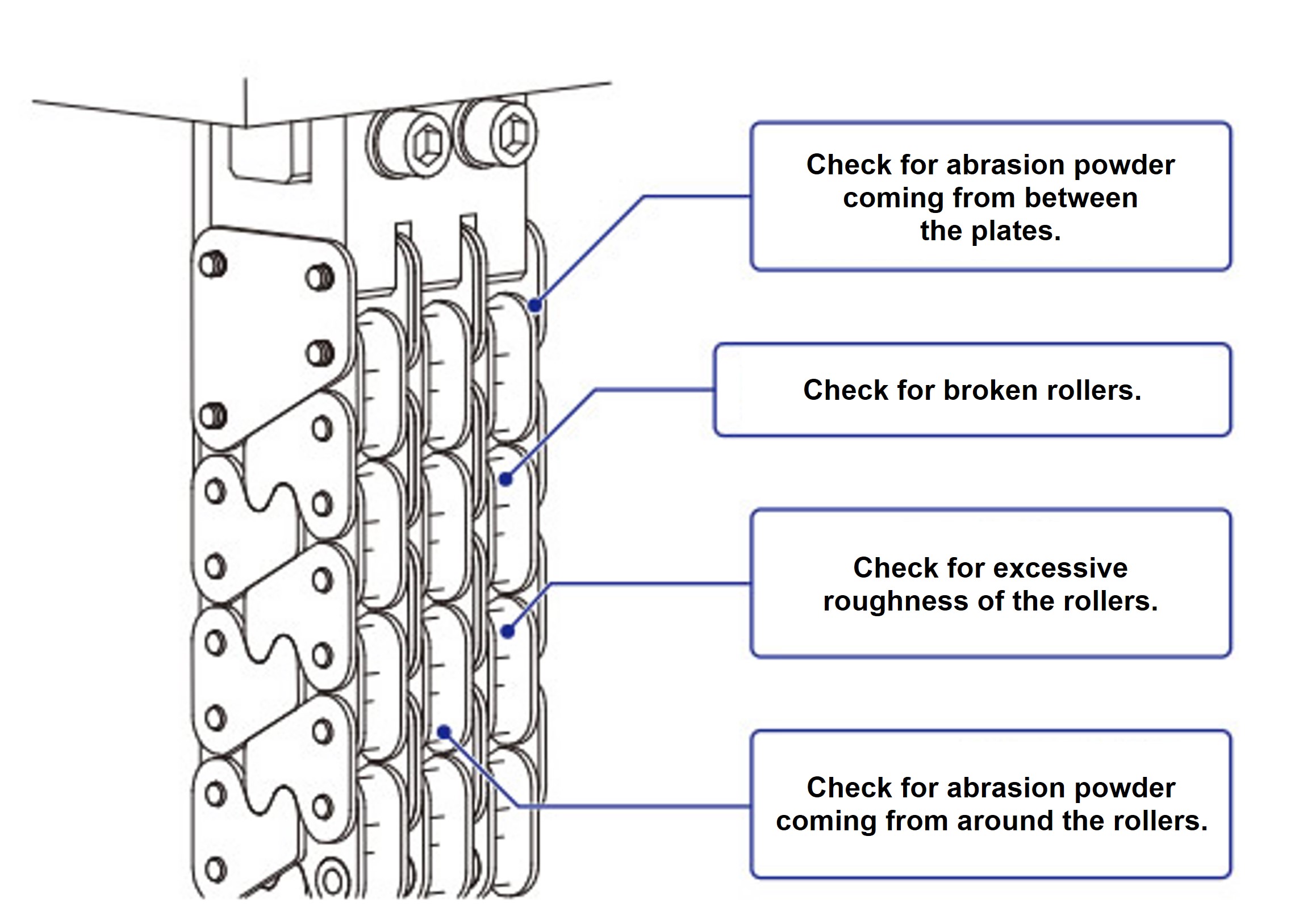

2. Inspect ZIP CHAIN (Every 1 months )

- (1)Remove any objects being conveyed.

- (2)Implement fall prevention measures to ensure the lifted portions do not fall.

- (3)Check the entire length of ZIP CHAIN for the following.

- ・Abrasion powder (reddish-brown) coming from between the plates

- ・Abrasion powder (reddish-brown) coming from around the chain rollers

Lubricate the chain immediately if either of the above are found. - ・Broken rollers

- ・Chain roller roughness caused by wear, noticeable by touch

Discontinue use and contact a Tsubaki representative if either of the above are found.

3. Greasing

See the following table for detailed lubrication information.

| Use classification | Greasing amount | Recommended lubricant name | Lubrication cycle | |

|---|---|---|---|---|

| Zip Chain | 10 to 15g per 100mm of stroke | Class 1 No. 2 high-load grease or equivalent Shell Gadus S2 V220 J 2 (EP) (Shell Lubricants Japan K.K.) |

Every 3 months or 100,000 trips | |

| Linear guide | ZMEL0200U ZMEL0500H |

4.5 to 6.5g (approximately 4.6 cc) per block | ||

| ZMEL1000M | 9.0 to 13.5g (approximately 9.8 cc) per block | |||

※Former name:SHELL ALBANIA EP grease 2

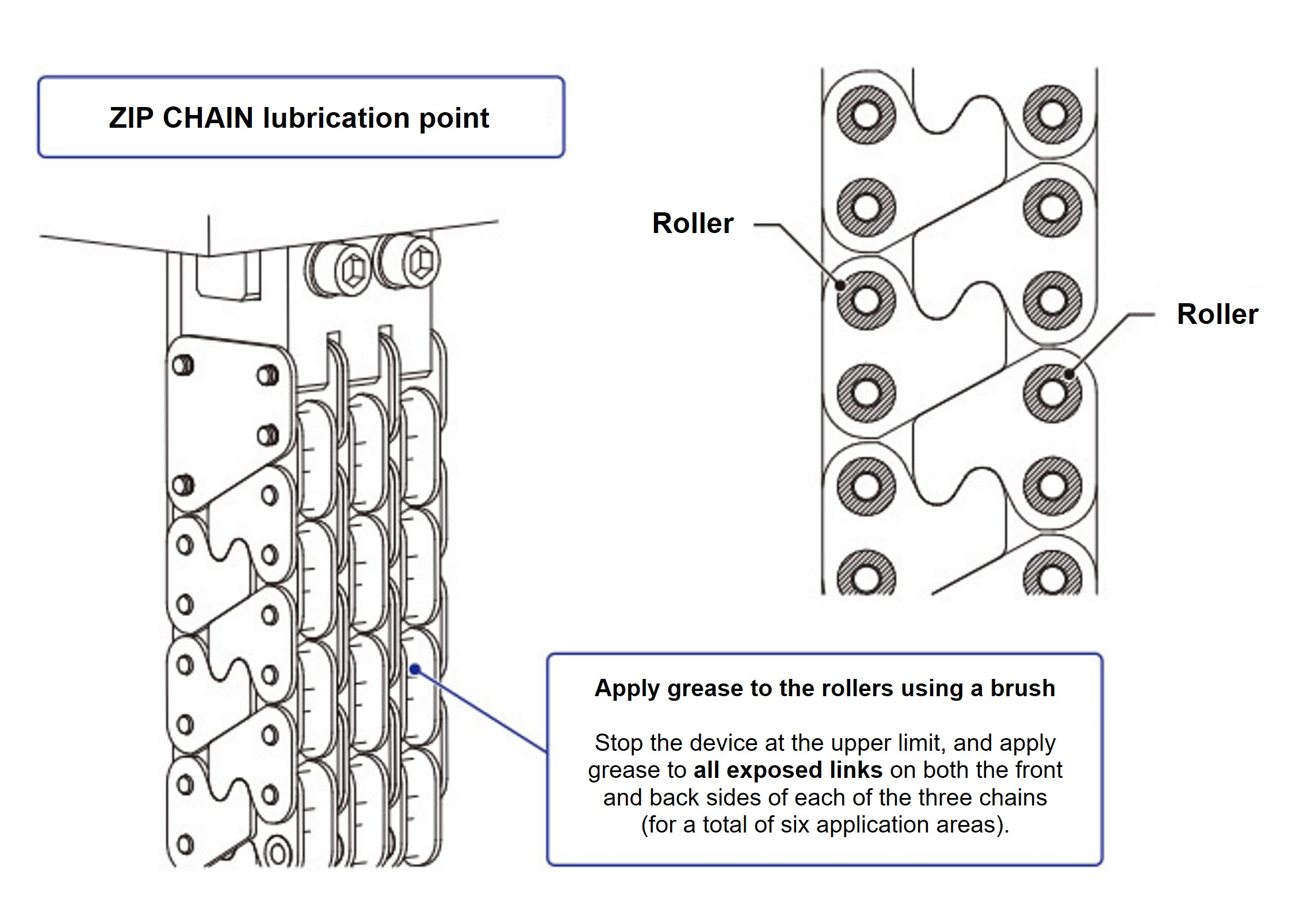

(Lubricating ZIP CHAIN )

Follow the steps below to lubricate ZIP CHAIN.

- [1]Remove any objects being conveyed on the table frame.

- [2]Implement fall prevention measures to ensure the lifted portions cannot fall.

- [3]Lubricate all rollers as shown in the figure to the right.

(Lubricating the guide )

Apply the specified amount of grease using the grease nipple.

After lubricating, run in the chain and remove any excess grease before starting operation.