技術資料 カップリング 選定と手順

選定手順や注意事項等をご覧になりたい方は下記へお進みください。

製品シリーズの絞り込みや仮選定をご希望の方は

こちらをクリックしてください。

使用条件が決まっており詳細な選定をご希望の方は

こちらをクリックしてください。

パワーリジッドカップリング EPRシリーズ 選定

テーパロックの締付トルクと伝達トルク

| 形番 | EPR50 | EPR58 | EPR68 | EPR78 | |||||

|---|---|---|---|---|---|---|---|---|---|

| 加圧ボルト | M6 | M6 | M6 | M6 | |||||

| 締付トルク N・m{kgf・m} |

16.7{1.7} | 16.7{1.7} | 16.7{1.7} | 16.7{1.7} | |||||

| 軸穴径 | 16 | 90{9.2} | - | - | - | ||||

| 17 | 98{10.0} | - | - | - | |||||

| 18 | 106{10.8} | 78 {8.0} | - | - | |||||

| 19 | 115{11.7} | 94{9.6} | - | - | |||||

| 20 | 123{12.5} | 110{11.2} | - | - | |||||

| 22 | 139{14.2} | 141{14.4} | 144{14.7} | - | |||||

| 24 | - | 172{17.6} | 191{19.5} | - | |||||

| 25 | - | 188{19.2} | 216{22.0} | - | |||||

| 28 | - | - | 287{29.3} | - | |||||

| 30 | - | - | 334{34.1} | 176{18.0} | |||||

| 32 | - | - | 382{39.0} | 212{21.6} | |||||

| 35 | - | - | 454{46.3} | 264{26.9} | |||||

| 36 | - | - | - | 281{28.7} | |||||

| 38 | - | - | - | 316{32.2} | |||||

| 40 | - | - | - | 351{35.8} | |||||

| 42 | - | - | - | 385{39.3} | |||||

| 45 | - | - | - | 437{44.6} | |||||

| 48 | - | - | - | 489{49.9} | |||||

※太字は在庫軸穴径です。軸穴径の組合せは、こちらを参照ください。

選定

トルク容量

ご使用になるサーボモータの最大トルク(T'max)に起動停止による負荷の使用係数を乗じた最大トルク(Tmax)を算出してください。

テーパロックの伝達トルクでチェックしてください。

- Tmax = T'max × 使用係数(SF)

- Tmax:カップリングにかかる最大トルク N・m{kgf・m}

- T'max:サーボモータの最大トルク N・m{kgf・m}

| 負荷の種類 | 一様な負荷 | 中程度の変動負荷 | 激しい変動負荷 |

|---|---|---|---|

| 使用係数(SF) | 1.2 | 1.4 | 1.5 |

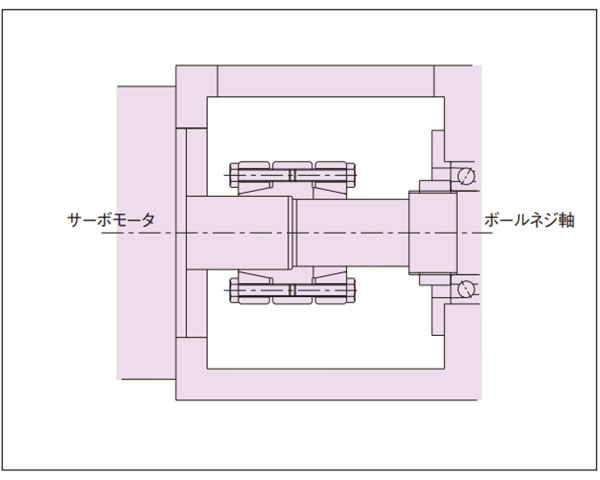

取付例