Technical Data Reducers Worm Gear Reducers Motor Specifications

Brake

1. Brake Characteristics

| Motor Output | 3 Phase | 0.1kW | 0.2kW | 0.4kW | 0.75kW | 1.5kW | 2.2kW | 3.7kW | 5.5kW |

|---|---|---|---|---|---|---|---|---|---|

| Brake model number | 3 Phase 200V | SLB01 | SLB02 | SLB04 | SLB07E | SLB15 | SLB22 | VNB371K NB-31190 | VNB55KE |

| 3 Phase 400V | SLB01 | SLB02 | SLB04V | SLB07E 180V | SLB15 180V | SLB22 180V | VNB371KV NB-31192 | VNB55KE | |

| DC rectifier number | 3 Phase 200V | DM200D | DM200D | PM180B | |||||

| 3 Phase 400V | DM400D | ||||||||

| Braking torque | Static friction torque N・m | 0.98 | 1.96 | 3.92 | 7.35 | 15 | 22 | 37 | 55 |

| {kgf・m} | 0.1 | 0.2 | 0.40 | 0.75 | 1.50 | 2.20 | 3.77 | 5.61 | |

| Dynamic friction torque N・m | 0.78 | 1.57 | 3.14 | 5.88 | 12.0 | 17.6 | 29.6 | 44 | |

| {kgf・m} | 0.08 | 0.16 | 0.32 | 0.60 | 1.20 | 1.79 | 3.02 | 4.48 | |

| Voltage | 3 Phase 200V | DC90V | DC90V | Instant 180V Constant 50V |

|||||

| 3 Phase 400V | DC180V | ||||||||

| Current at20 ℃ A |

3 Phase 200V | 0.178 | 0.178 | 0.232 | 0.273 | 0.289 | 0.289 | 0.261 | 0.253 |

| 3 Phase 400V | 0.142 | 0.145 | 0.145 | 0.135 | |||||

| capacity | at 20 ℃ W | 16.0 | 16.0 | 20.9 | 24.6/25.5 | 26.0/26.1 | 26.0/26.1 | 26.1/26.1 | 12.6/40.7 |

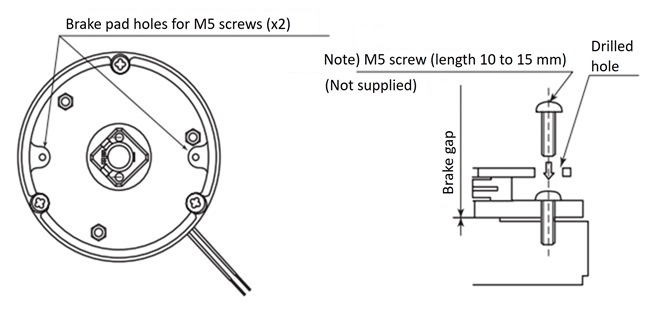

| Initial gap mm | 0.15 ~ 0.20 | 0.15 ~ 0.20 | 0.15 ~ 0.20 | 0.15 ~ 0.20 | 0.15 ~ 0.20 | 0.15 ~ 0.20 | 0.3 | 0.35 | |

| Limit gap mm | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 1.2 | 1.2 | |

| Moment of Inertia kg・m2 | 0.02×10-3 | 0.04×10-3 | 0.04×10-3 | 0.11×10-3 | 0.21×10-3 | 0.50×10-3 | 0.50×10-3 | 1.70×10-3 | |

| GD2 kgf ・m2 | 0.10×10-3 | 0.15×10-3 | 0.15×10-3 | 0.44×10-3 | 0.80×10-3 | 2.00×10-3 | 2.00×10-3 | 6.8×10-3 | |

| Total braking workload J {kgf・m} |

1.31×108 | 1.85×108 | 1.85×108 | 3.66×108 | 3.73×108 | 3.73×108 | 13.5×108 | 24.7×108 | |

| 1.34×107 | 1.89×107 | 1.89×107 | 3.73×107 | 3.81×107 | 3.81×107 | 13.8×107 | 25.2×107 | ||

| Allowable start-up frequency times | 10 times/min. | ||||||||

| Braking delay time S(Reference ) |

AC internal wiring | 0.18 ~ 0.25 | 0.15 ~ 0.21 | 0.14 ~ 0.17 | 0.20 ~ 0.24 | 0.30 ~ 0.45 | 0.30 ~ 0.45 | 0.50 ~ 0.70 (0.40 ~ 0.60) |

- |

| AC external wiring | 0.11 ~ 0.18 | 0.09 ~ 0.12 | 0.06 ~ 0.09 | 0.10 ~ 0.13 | 0.10 ~ 0.13 | 0.10 ~ 0.13 | 0.20 ~ 0.40 | - | |

| AC external operation | 0.11 ~ 0.18 | 0.09 ~ 0.12 | 0.06 ~ 0.09 | 0.10 ~ 0.13 | 0.10 ~ 0.13 | 0.10 ~ 0.13 | 0.20 ~ 0.40 | 0.03 ~ 0.05 | |

| DC external wiring | 0.05 ~ 0.07 | 0.04 ~ 0.06 | 0.03 ~ 0.05 | 0.04 ~ 0.06 | 0.01 ~ 0.06 | 0.01 ~ 0.06 | - (0.02 ~ 0.04) |

- | |

- Note 1)The rated torque values shown above are static and dynamic friction torque values after break-in.

- Note 2)The braking delay time is included as a reference and may differ depending on the braking conditions, operating conditions, and individual differences. To shorten the braking delay time (for lifting equipment, etc.), using DC external wiring is recommended.

- Note 3)The values for current and capacity are the values in the case of 200 V/400 V.

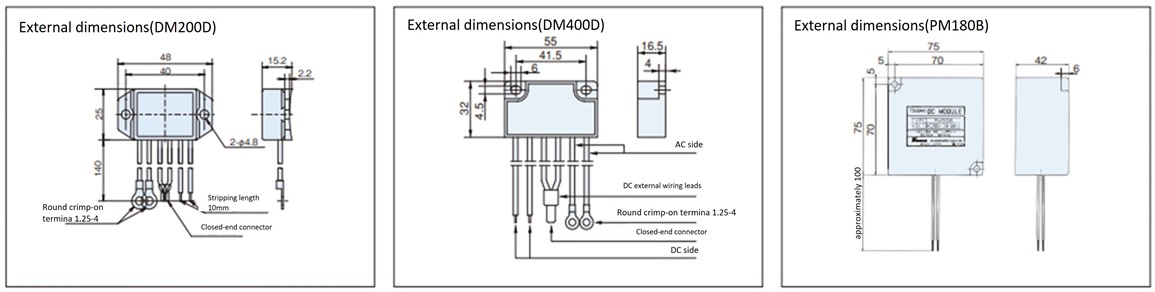

2. Rectifier (DC rectifier )

The built-in DC module is connected with the motor lead wire. When DC external wiring on brake, specify at time of order or connect as shown in the wiring diagram.

In case you do not prefer pre-wired to the motor leads, specify at time of order.

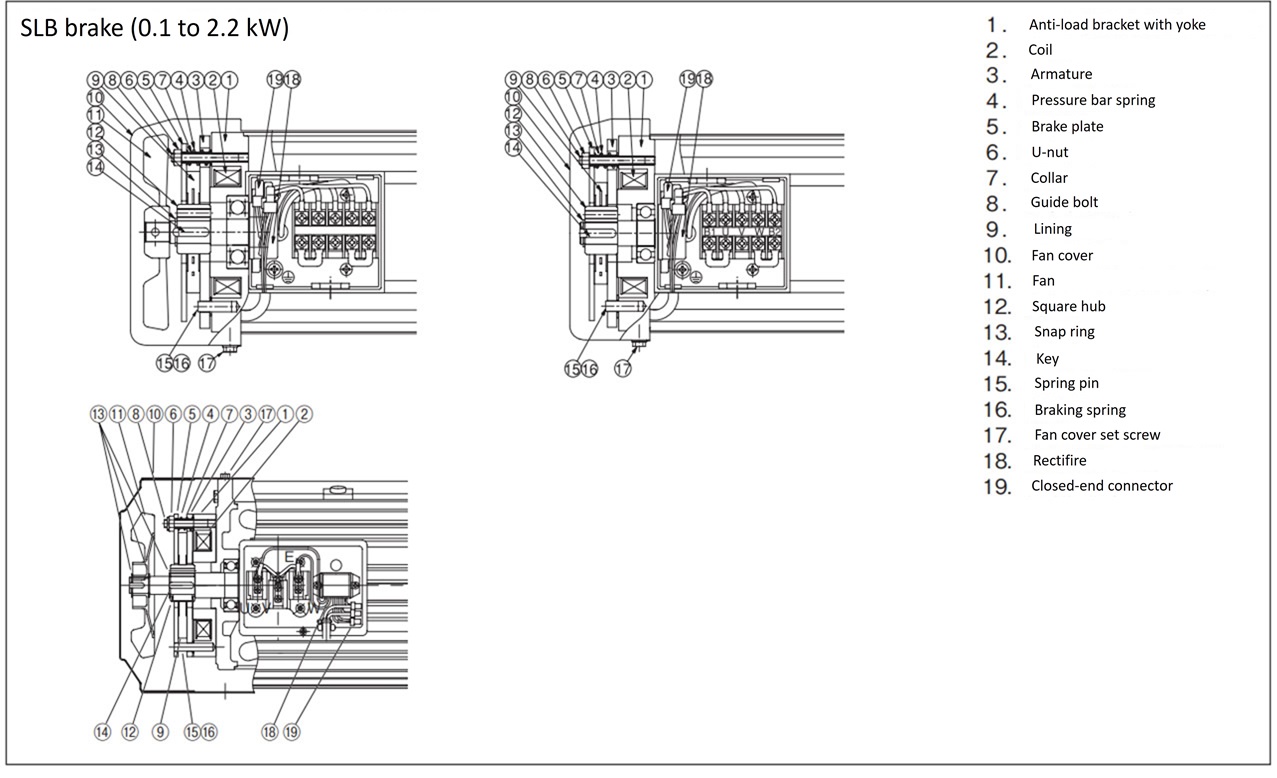

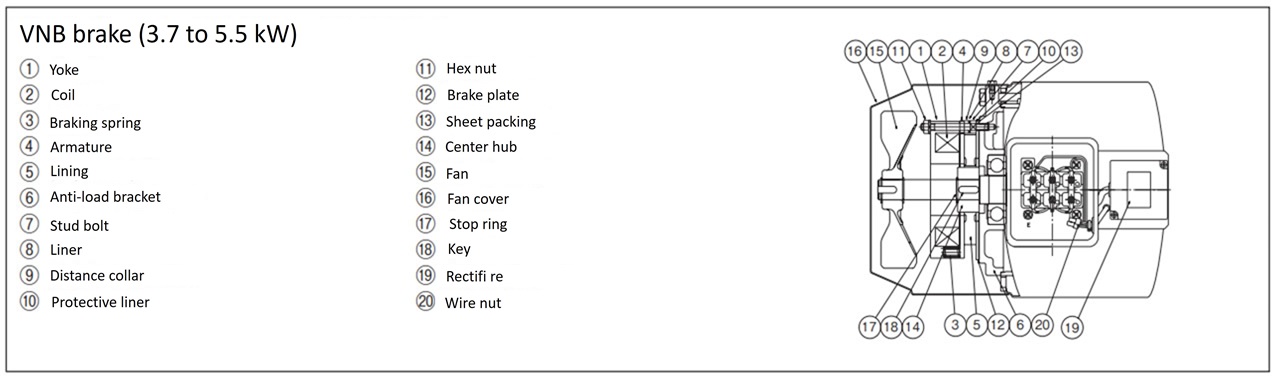

3. Brake structure

※Manual release [standard :0.1kW~2.2kW]

- ・Make sure to remove the load on output shaft, then release the brake.

- ・Remove the fan cover and attach the screws.

- ・Make sure to remove the screws and replace the fan cover before operating the motor.

Note) 1.5 kW and 2.2 kW motors: screw size = M6