技術資料 小形コンベヤチェーン 取扱

点検

初期のなじみ期間は、調整を行うために点検を適宜行ってください。次の諸項について点検をします。

- (1)チェーンの異常な摩耗。

- (2)チェーンのたるみ。

- (3)チェーンの脈動とシャクリ。

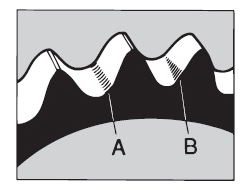

- (4)スプロケットの異常摩耗、心振れによる異常な当たりきず。スプロケット歯底のゴミの堆積。スプロケットの正常な噛合いは、当たりの状態が図のAのように一様に当たっています。Bのように偏っているのは、スプロケットの取付け不良か、チェーンがねじれているなどが原因ですから再点検してください。当たりの位置は、歯底(谷)から少し上った所が正常です。ただし、初期張力をかけてたるみ側に張力が残っている場合には、わずかに歯底(谷)に当たりますが、この場合にも、当たりが強いのはAの位置です。アイドラー、タイトナーの場合は、歯底(谷)の中央で当たっています。

図28. スプロケットの歯当たり

- (5)ガイドレールの過大な摩耗。

- (6)潤滑系統の異常。

・チェーンの脈動、シャクリ、異常な摩耗の原因

- (1)オーバロード、破片などの噛込み。

- (2)帰り側でのチェーンのバックベンド。

- (3)不十分な潤滑、または無潤滑。

- (4)スプロケットの摩耗。

- (5)チェーンの変則的な摩耗や破断。

張りの調節

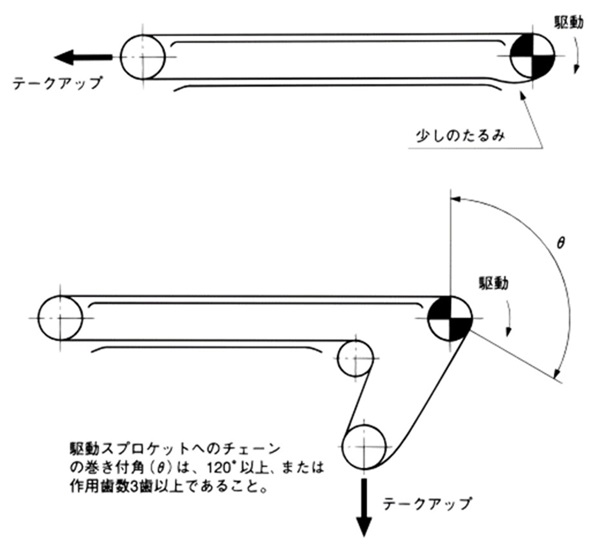

チェーンの張りは、強くなり過ぎないように適当なたるみを持たせておくことが必要です。

チェーンを張過ぎるとチェーンの摩耗が促進され、また、たるみ過ぎるとチェーンがスプロケットの歯に乗上げて故障の原因となります。

1. 調節の頻度

チェーンは、当初のなじむまでの伸び(初期伸び)と、運転後のピン~ブシュ間の摺動部の摩耗によって伸びます。したがって常に適当なチェーンの張りを得るために、テークアップによって適宜調整を行う必要があります。

1日8時間運転とした場合の、チェーンの点検調節回数の目安は下表のとおりです。長時間使用していますと、テークアップの点検が怠りがちとなり、チェーンにたるみが生じ、事故を誘発することになる場合がありますので、ぜひ定期的に点検してください。運転時間が長い時は、点検の間隔を縮めてください。

| 運転開始後1週間以内 | 毎日1回 |

| 同 1ヵ月以内 | 毎週2回 |

| 1ヵ月経過後 | 毎月2回 |

2. テークアップで調節しきれない時

3. テークアップの調節は左右均等

2条のチェーンに別個のテークアップがついている場合は、調節ストロークが左右同量となるようご注意ください(連動テークアップ、あるいは、バランス式テークアップなどではその必要はありません)。

左右不均等に調節が行われると、チェーンのプレートとスプロケットの歯の側面が当たり、無理な荷重の原因となります。左右均等になっていないときは、左右のチェーンの一部を入替えるなどの処理を施し、均等にしてください。