技術資料 クラッチ 取扱

MLシリーズ 取扱注意

- 1. スプロケット、ギヤ、プーリなど取付けられるものの軸穴仕上げ公差はH6またはH7を推奨します。

- 2. MLシリーズを取付ける軸の仕上げ公差はh6またはh7を推奨します。

- 3. MLシリーズ外輪と取付けるスプロケット、ギヤ、プーリなどの間に取付けるキー及びMLシリーズを取付ける軸とMLシリーズ内輪の間のキーはJIS B1301-1996(新JIS)平行キー(普通形)をご使用ください。外輪のキー寸法は、JISで規定している軸径とキーの関係通りにはなっていませんので、ご注意ください。打込みキーなどでキーの天井を利かすことは絶対に避けてください。

- 4. プーリなどを取付けられる場合、空転中にMLシリーズに作用するラジアル荷重がMLシリーズの空転許容ラジアル荷重を上回る場合には下記のように荷重のかかる部分に別途ベアリングで荷重を受ける取付けとしてください。

- 5. 周囲に粉塵が多い場合やカムクラッチに適さないオイルが飛散する場合、グリス漏れを防止する場合などではML-2GDシリーズのご使用を推奨します。ML-2GDシリーズは、異物の侵入防止を目的としたダストシールを装着しています。ML-2GDシリーズの最高空転回転速度はMLシリーズの約80%程度にとどまります。

- 6. MLシリーズを軸に取付ける場合、回転方向を確認し内輪端面にのみ力を掛けて静かに取付けてください。

- 7. カムクラッチにスラスト荷重がかかる場合は、別途スラスト荷重を受けるものを設けてください。またヘリカルギヤなどご使用中にスラスト荷重が作用する場合、故障の原因となりますのでご使用を避けてください。

- 8. ご使用可能な周囲温度は-30℃~40℃です。

- 9. 潤滑およびメンテナンスについてはこちらを参照ください。

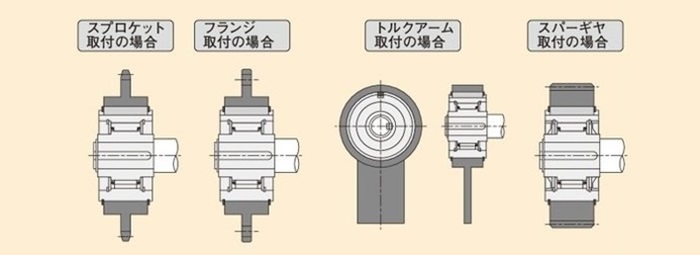

取付例

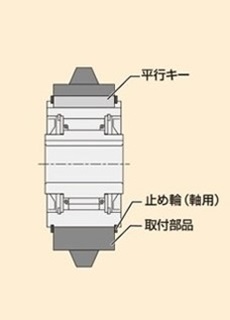

・ベアリングを使用しない場合

カムクラッチの回転方向を確認し、片側の止輪溝に止め輪を取付けてください。

スプロケットなどの伝動部品を平行キーを使用し装着してください。

もう一方の止輪溝に止め輪を取付けてください。

MLシリーズ ML-2GDタイプ[ダストシール付]

取付例

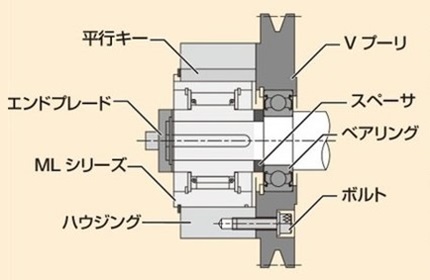

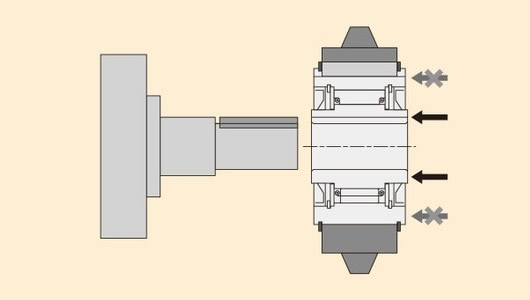

・ベアリングを使用する場合

軸にベアリングとVプーリなどの部品を取付け、スペーサを取付けてください。

カムクラッチの回転方向を確認し、プーリなどに取付けるハウジングを外輪に平行キーを使用して装着してください。

外輪に付属の止め輪(軸用)を取付けてください。

MLシリーズを軸に取付けた後Vプーリなどの部品と強度区分10.9のボルトとばね座金にてしっかり固定ください。

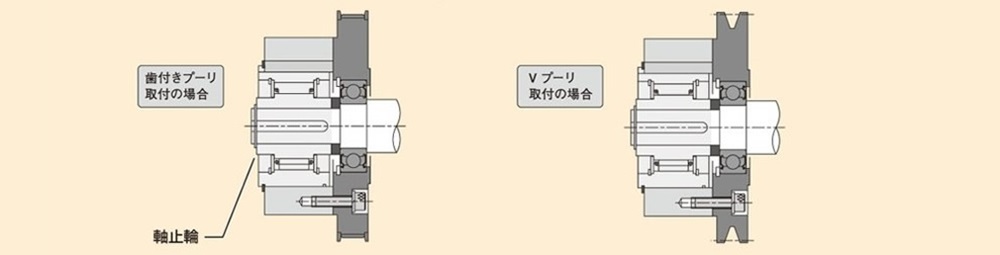

取付例

・軸への取付方法

カムクラッチの回転方向を確認し取付けた後、軸止輪または、エンドプレートとボルトで軸に固定してください。

内輪端面のみに力を掛けて静かに取付けてください。