リニパワージャッキ簡易選定ツール

対象品種

リニパワージャッキ JWB(ボールネジタイプ)

リニパワージャッキ JWH(ハイリードボールネジタイプ)

リニパワージャッキ JWM(台形ネジタイプ)

コンテンツの利用について

- つばき産業用機械製品 情報サイト リニパワージャッキ簡易選定ツール(以下、「本ツール」といいます」)をご利用いただくにあたって、以下のご利用上の注意事項・免責事項を必ずお読みいただき、すべての内容に同意していただける場合のみご利用ください。

- 同意いただけない場合は、本ツールのご利用をお控えください。

ご利用上の注意事項 ・ 免責事項

選定計算 リニパワージャッキ

- ・ご要求の仕様に見合う形番を選定いたします。

- ・選定条件などをご入力後、画面最下部の判定ボタンをクリックしてください。

- ・ジャッキ1台においての選定計算ソフトです。

複数台数での選定におきましては、[STEP1 リニパワージャッキの選定 2.ジャッキ1台当たりの荷重Wの算出]をご参照ください。 - ・ジャッキ連動運転・周辺機器選定サービス

ジャッキ連動システムにおいて、リニパワージャッキだけでなく、ギヤボックス・カップリング・駆動部を含めて

選定、提案させていただきます。見積図面・レイアウト図の作成もいたしますので、是非ご利用ください。

選定条件を入力

選定条件を入力してください。

| 昇降荷重(最大) | W0 = | [kN] | [kgf] |

表1 使用係数 sf

注) 上記使用係数表は一般的な目安です。使用条件を考慮して決定ください。 |

||||||||||||

| 昇降荷重(最小) | W1 = | [kN] | [kgf] | |||||||||||||

| 使用係数 | Sf = | |||||||||||||||

| 座屈強度確認荷重 | W2 = | [kN] | [kgf] | |||||||||||||

| 希望昇降速度 | V' = | [m/min] | [mm/s] | |||||||||||||

| ストローク | ST0 = | [mm] | ||||||||||||||

| 実ストローク | ST = | [mm] | ||||||||||||||

| 運転頻度 | [往復/Hr]× [Hr/日]× [日/年] | |||||||||||||||

リニパワージャッキ仕様決定

リニパワージャッキの仕様を選択してください。

| JW | M | 050 | U | S | H | 10 | U |

| | シリーズ名 リニパワー ジャッキ |

| | | | | | | | | | | | | | |

| 基本容量 002:1.96kN{0.2tf} 005:4.90kN{0.5tf} 010:9.80kN{1tf} 025:24.5kN{2.5tf} 050:49.0kN{5tf} 100:98.0kN{10tf} 150:147kN{15tf} 200:196kN{20tf} 300:294kN{30tf} 500:490kN{50tf} 750:735kN{75tf} 1000:980kN{100tf} |

| | | | | | | | | | | | | | |

| | | | | | | | |

| ウォーム減速比 L、H 実際の減速比は 詳細情報を ご参照ください。 |

| 称呼ストローク 1:100mm 2:200mm 3:300mm 4:400mm 5:500mm 6:600mm 8:800mm 10:1000mm 12:1200mm 15:1500mm 20:2000mm |

| フランジ取付方向 ※トラベリングナット仕様の 場合のみ表記必要 |

| ネジ仕様 S:基本形 M:回り止め仕様 R:トラベリングナット仕様 |

|||||||

| ネジ種類 M:台形ネジ B:ボールネジ H:ハイリードボールネジ |

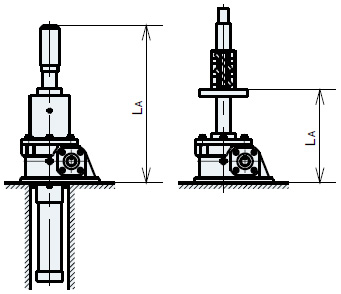

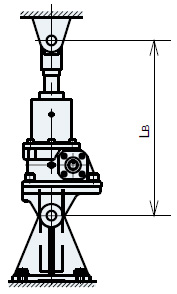

取付形状 U:押上用 D:吊下用 |

注) | ハイリードボールネジタイプ(ネジ種類:H)の 回り止め仕様(ネジ仕様:M)は見積り品となります。 ご使用条件をご連絡ください。 |

||||

| ネジ種類 | 基本容量 | ネジ仕様・取付形状 | ウォーム減速比 | フランジ取付方向 | 先端金具 | ジャバラ | クレビス金具 |

| ・センサー系オプション | ・入力系オプション | |||

| カウンターLS | 内部LS | ポテンショメータ | エンコーダ | モータ |

ジャッキ形番

| 基本容量 | [kN] | 総合効率 ηJ | |||

| ネジ谷底径 d | [mm] | 最大許容入力容量 | [kW] | ||

| ネジリード L | [m] | 許容無負荷空転トルク T0 | [N・m] | ||

| ウォーム速比 R | 許容入力軸トルク | [N・m] |

判定:

実速度の確認

モータ回転速度、実際の総減速比を入力してください。

| モータ回転速度 | Nm = | [r/min] |

| 必要入力回転速度 | N' = V'/L×R = | [r/min] |

| 必要減速比 | i' = Nm/N' = |

| 50Hz | 1500 r/min |

| 60Hz | 1800 r/min |

| 実際の総減速比 | i = | (ジャッキ入力軸から駆動モータまでの総減速比を入力) |

| 実昇降速度 | V = Nm×L/(i×R) = | [m/min] |

| [mm/s] |

諸元

| 必要入力軸トルク | T = W0×Sf×1000×L/(2π×R×ηJ)+T0 | = | [N・m] | |

| 必要逆転トルク(参考値) | T' = W0×Sf×1000×L×ηJ/(2π×R)-T0 | = | [N・m] | |

| 入力回転速度 | N = V/L×R | = | [r/min] | |

| 必要入力容量 | P = T×N/9550 | = | [kW] | |

| 入力軸慣性モーメント | IJ = W0×1000/g×{L/(2π×R)}2 | = | [kg・m2] |

判定:

座屈強度確認

据え付け状態を選択してください。

| 据え付け状態 | |||

| 支持係数 | m = | ||

| 作用点間距離 | L1 = | [mm] | |

| 座屈強度 | PCR = m×(d2/L1)2/1000 = | [kN] | |

| 座屈安全率 | SF = PCR/(W2×Sf) = | (>=4) | |

判定:

許容ネジ軸回転速度確認(トラベリングナットのみ)

使用頻度確認

| 使用時間 | ts = ST/(V×1000) = | [min] | |

| 負荷時間率(%ED) | %ED = [往復/Hr]×2×使用時間×100/60 = | [%ED] |

判定:

期待寿命計算(台形ネジタイプ)

| 年間総走行距離 | Ly = ST×2×[往復/Hr]×[Hr/日]×[日/年]×10-6 = | [km] |

| 期待寿命 | Z = (JWM050以下:5km, JWM100以上:1km)/Ly = | [年] |

期待寿命計算(ボールネジタイプ)

| 等価荷重 | PE = (W0×Sf×2+W1)/3 = | [kN] |

| ボールネジ動負荷容量 | C = | [kN] |

| 短ストローク補正係数 | fs = | |

| 運転条件係数 | fd = | |

| 焼入硬度補正係数 | fh = | |

| 寿命補正係数 | f1 = (PE×fd)/(C×fh×fs) = | |

| B10寿命総走行距離 | L10 = 250/f13 = | [km] |

| 年間総走行距離 | Ly = ST×2×[往復/Hr]×[Hr/日]×[日/年]×10-6 = | [km] |

| 期待寿命 | Z = L10/Ly = | [年] |

期待寿命計算(ハイリードボールネジタイプ)

ハイリードタイプの期待寿命計算につきましては、別途お問い合わせください。

選定結果

形番

:

必要入力容量

:

[kW]

減速比

:

<注意>

本選定は理論計算値に基づいて選定を行ったもので、選定結果を保証するものではありません。

本選定の計算式を十分にご理解いただいた上で、計算結果に余裕を見込むなどして、

最終的な使用機器の決定は、お客様にてご判断くださいますようお願い致します。