パワーロック簡易選定ツール

対象品種

パワーロック:

ASシリーズ、AS-KPシリーズ、AS-SSシリーズ

AD-Nシリーズ、AD-N-KPシリーズ、AEシリーズ

RE-SSシリーズ、KEシリーズ、KE-KPシリーズ

KE-SSシリーズ、KE-LPシリーズ、TFシリーズ

TF-KPシリーズ、MLシリーズ、EFシリーズ、ELシリーズ

コンテンツの利用について

- つばき産業用機械製品 情報サイト パワーロック簡易選定ツール(以下、「本ツール」といいます」)をご利用いただくにあたって、以下のご利用上の注意事項・免責事項を必ずお読みいただき、すべての内容に同意していただける場合のみご利用ください。

- 同意いただけない場合は、本ツールのご利用をお控えください。

ご利用上の注意事項 ・ 免責事項

選定計算 パワーロック

ご指定の条件に基づき、該当するパワーロックを選定いたします。

「軸径から選定」の場合、指定の軸径に合う形番を選定し、指定のトルクを満たすかどうかを判定します。

「トルクから選定」の場合、指定のトルクを満たす最小軸径の形番を選定します。

いずれの場合においても、軸及びボスの面圧許容の判定・必要最小ボス外径及び中空軸最大内径・

ラジアル荷重許容の判定を表示しますのでご確認ください。

選定条件を入力

軸径を入力

軸径: mm

伝達トルクを入力

伝達トルク: N・m

使用係数:

伝達容量: kW

回転速度: r/min

スラスト荷重がかかる場合は入力

スラスト荷重: N

ラジアル荷重がかかる場合は入力

ラジアル荷重: N

軸・ボス材料の降伏点を入力

軸材料降伏点 : MPa

ボス材料降伏点: MPa

伝達トルク計算結果

N・m

※必要最小ボス径には安全率を見込んでおりません。

詳細な選定手順及び計算式はこちらをご覧ください。

選定結果

|

シリーズ 特徴一覧 |

取付例 クリックで 説明図表示 |

形 番 クリックで 製品情報表示 |

軸径 [mm] |

外径 [mm] |

許容 トルク [N・m] |

トルク 判定 |

単価/納期 -複数個の場合- 使用個数 トルク倍率 合計価格 |

シリーズ 係数 K2 |

軸側 面圧 [Mpa] |

軸側 面圧 判定 |

ボス側 面圧 [Mpa] |

ボス側 面圧 判定 |

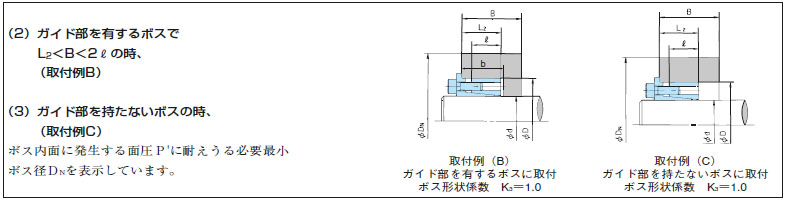

ボス形状 係数 K3 |

必要最小 ボス外径(*) [mm] |

中空軸 最大内径 [mm] |

ラジアル 荷重判定 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AS | ||||||||||||||||

| AS-KP | ||||||||||||||||

| AS-SS | ||||||||||||||||

| AD-N | 取付例A | |||||||||||||||

| 取付例B,C | ||||||||||||||||

| AD-N-KP | 取付例A | |||||||||||||||

| 取付例B,C | ||||||||||||||||

| AE | 取付例A | |||||||||||||||

| 取付例B,C | ||||||||||||||||

| RE-SS フランジ 取付 |

取付例A | |||||||||||||||

| 取付例B,C | ||||||||||||||||

| RE-SS ストレート 取付 |

取付例A | |||||||||||||||

| 取付例B,C | ||||||||||||||||

| KE | 取付例A | |||||||||||||||

| 取付例B,C | ||||||||||||||||

| KE-KP | 取付例A | |||||||||||||||

| 取付例B,C | ||||||||||||||||

| KE-SS | 取付例A | |||||||||||||||

| 取付例B,C | ||||||||||||||||

| KE-LP | 取付例A | |||||||||||||||

| 取付例B,C | ||||||||||||||||

| TF | 取付例A,B | |||||||||||||||

| 取付例C,D | ||||||||||||||||

| TF-KP | 取付例A,B | |||||||||||||||

| 取付例C,D | ||||||||||||||||

| ML | ||||||||||||||||

| EF | 取付例A,B | |||||||||||||||

| 取付例C,D | ||||||||||||||||

| EL(※) |

推奨 締結例(1) |

|||||||||||||||

|

推奨 締結例(2) |

※ELシリーズについては、上記の推奨締結例に示すボルトのサイズ・本数・締付トルクで加圧した場合の計算結果です。

この例以外での加圧条件での選定については弊社までお問い合わせください。

| シリーズ |

形 番 クリックで 製品情報表示 |

軸径 [mm] |

外径 [mm] |

許容 トルク [N・m] |

トルク 判定 |

単価/納期 | シリーズ 係数 K2 |

軸側 面圧 [Mpa] |

軸側 面圧 判定 |

ボス 外径側 面圧 [Mpa] |

ボス 外径側 面圧 判定 |

必要 ボス材 降伏点 |

ボス 強度 判定 |

中空軸 最大内径 [mm] |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SL | 候補1 | ||||||||||||||

| 候補2 | |||||||||||||||

| 候補3 | |||||||||||||||