適用事例集 カムクラッチ - 16. 縦型ポンプ, 縦型モータ

アプリケーション

バックストップ

逆転防止とも言います。

機械の稼働中はカムクラッチは空転を続け、まれに発生する逆転時にかみ合う使用法です。

対応機種

- ・特型カムクラッチ

採用機械

縦型ポンプ, 縦型モータ

適用事例

レイアウト

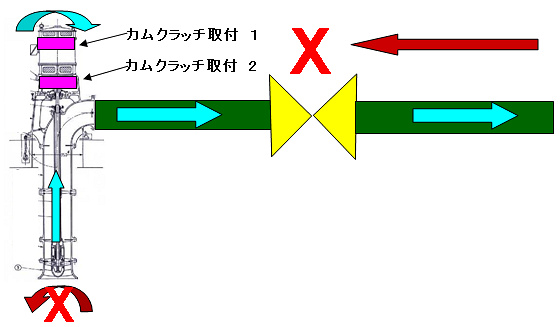

使用目的と動作説明

縦型ポンプや縦型モータにおいて、仕様または使用目的によっては逆転してはいけない場合があります。

上図はチェックバルブを取付けた例で、通常は  の方向に水などが流れます。

の方向に水などが流れます。

チェックバルブは水などが  へ逆流することを防ぐことを目的に使用されています。

へ逆流することを防ぐことを目的に使用されています。

またこのチェックバルブが破損した場合には、水などは逆流し、ポンプは高速で逆転させられる可能性

があります。

このような逆転が発生した場合には、メタル軸受けの潤滑を損なうなどの原因により破損に至る場合が

あります。

カムクラッチを逆転防止装置として上図取付1又は2の箇所に取付ることが有効になります。

ラチェットは、一つの歯で負荷を受けることから大寸法となり、歯欠け音発生等の恐れがあります。

つばき カムクラッチでは・・・

縦型ポンプや縦型モータでの取付箇所や潤滑方法に基づき適切なカムクラッチを選択することが可能です。

比較的高速で回転する縦型ポンプまたは縦型モータの逆転防止としてBRまたはBR-Pシリーズが適当な例があります。ポンプやモータの運転中、カムがリフトオフ(浮き上がる)し、内外輪と非接触状態になりますので、長寿命が期待できます。

カムクラッチ使用のメリット

- ・カムクラッチは正転時に空転、逆転時時は自動的にかみ合いを行います。

- ・ラチェットなどに比べ、多くのカムで負荷を受け持ちコンパクトになります。