適用事例集 カムクラッチ - 10. 2方向コンベア

アプリケーション

オーバランニング

カムクラッチの内外輪がかみ合ってトルクが伝達されている場合と、内外輪の回転速度の差や回転方向の違いによって、

空転を続ける場合とが任意に繰り返される使用法です。自動車のフリーホイルの動きと同様です。

対応機種

- ・MZシリーズ等

採用機械

2方向コンベア

適用事例

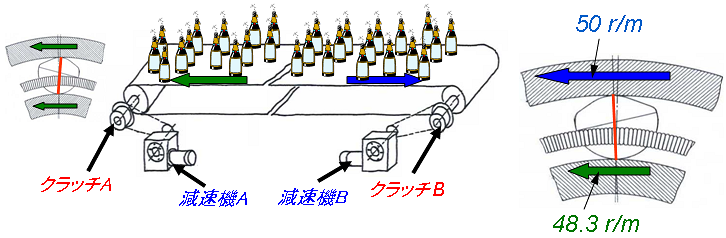

レイアウト

使用目的と動作説明

上記のような正逆に搬送するコンベアでの搬送物を倒さないことを目的にカムクラッチが使用された事例です。

カムクラッチを使用することにより、一定のテンションをコンベア上部に与えることが可能になります。

コンベアを緑矢印方向に移動させる際には、減速機A・Bとも同一方向に駆動をかけます。この時カムクラッチAはかみ合い、コンベアを緑矢印方向に移動させます。

次に、コンベアを青矢印方向に移動させる際には、減速機A・Bとも上記と反対方向に駆動をかけます。

この時カムクラッチBはかみ合い、コンベアを青矢印方向に移動させます。

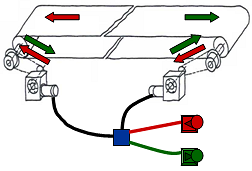

緑矢印方向に移動させる際には、カムクラッチA側は負荷を受け待ちますが、カムクラッチB側は負荷を受けないため、モータのすべり分だけ早く回転します。この状況でカムクラッチBの内輪と外輪に回転差が生じ、カムクラッチは空転を行ないます。青矢印方向に移動するときも同様にカムクラッチAが空転します。

したがって、コンベアは張り側が常に一定となりコンベアがたるむことを防止できます。

もしカムクラッチを使用しない状態では、負荷を受けない側は負荷を受け持つ側より、モータのすべりがない分だけ早く回転しますので、コンベアにたるみが生じ一定のテンションを保つ事が出来ません。

上図ではコンベアが緑矢印方向に移動している状態で、減速機は50回転でカムクラッチAを介してコンベアを運転します。カムクラッチAは負荷を受け持つためすべりが発生し48.3回転となります。減速機Bは負荷を受けないため50回転で回転をしますが、カムクラッチBにより50回転はコンベアに伝わりません。

つばき カムクラッチでは・・・

取り付け軸径、必要トルク、回転数などに基づきカムクラッチの選定が必要です。

お客様の使用条件やスプロケット型番、取付方法に合わせて、カムクラッチを選択していただく事が可能です。

また周囲温度が高い場合等、潤滑条件についてもご使用条件に適した仕様を選択することができます。

カムクラッチ使用のメリット

- ・カムクラッチは回転数の差だけで自動的に空転とかみ合いを行います。

- ・空転とかみ合いを制御する装置不要で運転の切替が行えます。