トルクレンチひとつで

誰でも簡単切継ぎ

安全で迅速な

交換作業を実現します!

大形コンベヤチェーン継手リンク

スクリューロックリンク®

大形コンベヤチェーンの切継ぎでよくあるこんなお悩み、

「スクリューロックリンク」で解決します!

今までの切継ぎは...

ハンマー作業が危険

衝撃を伴う作業は、労災リスクをはらんでいます。ハンマーの当て方によっては、破片が飛散して目を負傷したり、誤って手を打ちつけたりすることも...。

スクリューロックリンクなら...

ハンマー作業が不要に

トルクレンチ一つで切継ぎができるので、危険なハンマー作業が不要に。安全な職場に貢献します。

今までの切継ぎは...

屈曲不良が起きることも

連結時、外プレートの位置調整が難しく、外プレートの押し込み過ぎによる屈曲不良が起きがちでした。屈曲不良はトラブルの原因になります。外プレートを押し込みすぎた場合、また一から連結をやり直すということも...。

スクリューロックリンクなら...

施工不良の回避が可能

テーパ構造より、プレートの正確な位置決めが可能なので、既定トルクでナットを締め付けるだけで適切な連結が可能です。施工不良を回避し、無駄な工数を削減することができます。

今までの切継ぎは...

トラブル時、すぐに復旧できない

作業工数がかかるのでライン停止時間が長くなり、生産性に影響が出ます。トラブル時迅速に対応するためには、作業者の手配が必要なことも...

スクリューロックリンクなら...

すぐに復旧可能

誰でも簡単に切継ぎができるので、作業員の手配なども必要なし。予備品として持っておけば、迅速な復旧が可能なので、生産ロスも最小限にできます。

今までの切継ぎは...

切継ぎに大掛かりな工具・治具が必要

チェーンが大きくなるにつれて、大掛かりな工具・治具が必要な場合も...

工具・治具の手配にかかる費用や作業工数も負担になります。

スクリューロックリンクなら...

トルクレンチ一つで簡単切継ぎ

必要なのはトルクレンチだけなので、大掛かりな工具や治具は不要になり、費用や作業工数削減につながります。作業が困難な狭所や昇降装置でも、簡単に切継ぎができます。

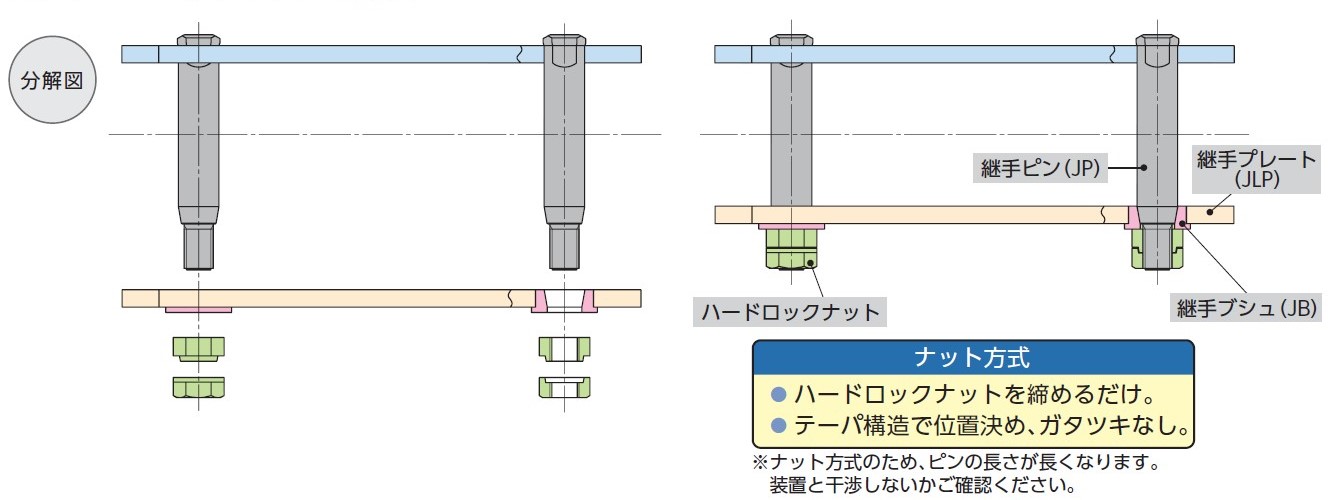

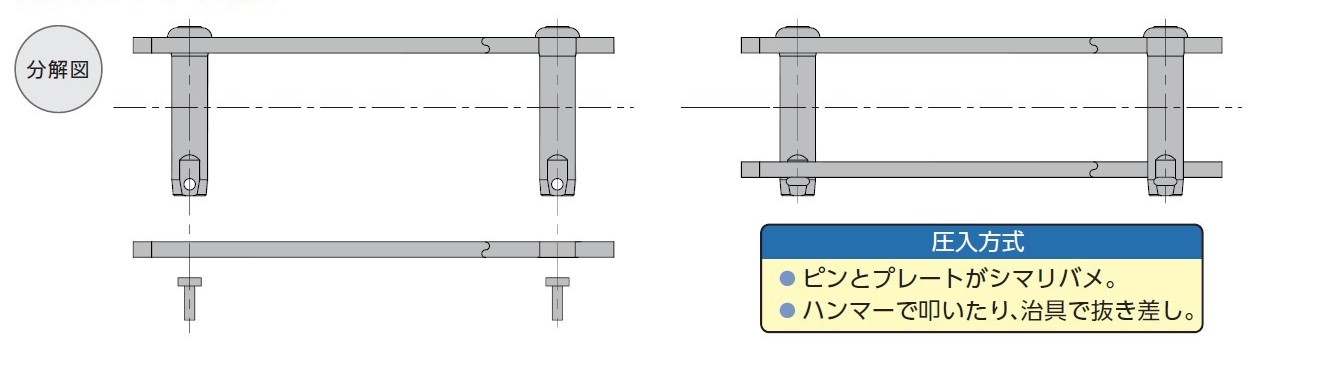

構造上の比較

スクリューロックリンクの構造

標準外リンクの構造

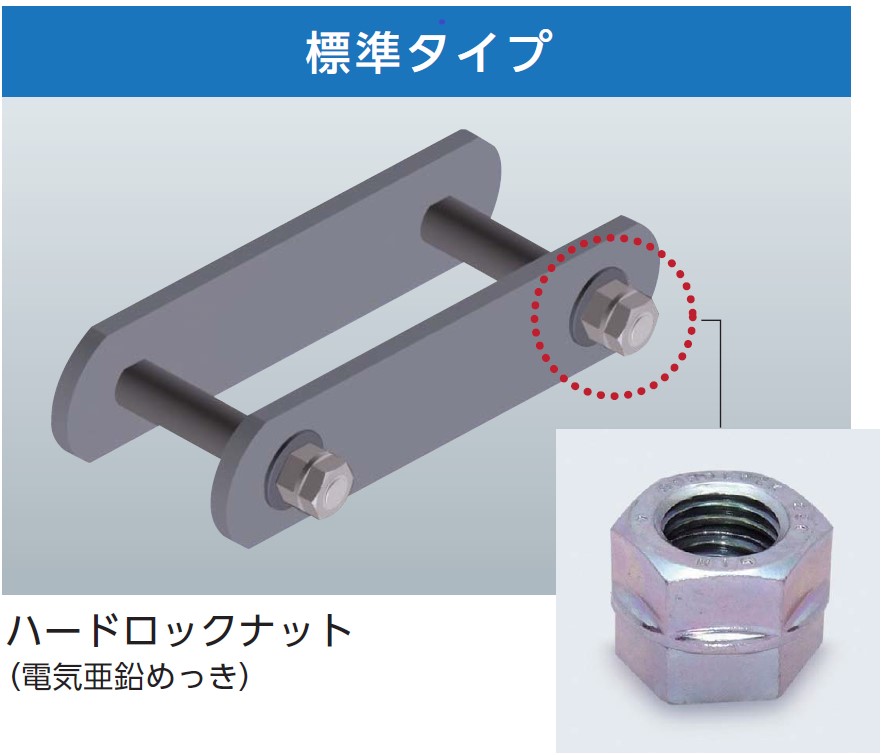

ナット部は選べる2タイプ

ピンの長さを極力抑えたショートタイプもご用意できます。

※ハードロックナット、ハードロックベアリングナットは、ハードロック株式会社の商標です。

スクリューロックリンク

vs

標準外リンク

交換作業性比較の動画

↑ 動画を再生する

製品ラインアップ

製品名称

スクリューロックリンク

適用仕様

- DT仕様、AT仕様など各種仕様に対応しています。

カタログ掲載サイズ

- RF10トン、12トン、17トン、26トン、

36トン、52トン、60トン、90トン

- 上記以外のサイズ(RF08トン、RF120トン、インチ系など)、仕様(ステンレス仕様など)も製作可能な場合があります。ご相談ください。

ホームページからのお問い合わせ/資料請求

製品お問い合わせ

各製品へのお問い合わせ及び製品カタログ・資料請求はこちらより承っております。

ご利用の際は当サイトの会員登録をお願いします。

【お問い合わせ】 |

【資料請求】 |

|---|

各種証明書の発行について

一部の証明書は弊社製造番号と紐づけて発行しております。

以下についてはご購入先を通じてご依頼ください。

・該非判定書

・EAR判定書

・原産地証明書

見積依頼、納期確認について

弊社では直接販売をしておりません。

購入価格・納期に関するお問い合わせはお取引のある商社様を通じてご確認ください。

購入先をお探しのお客様は取扱販売店一覧をご覧ください。

お問い合わせ窓口

製品窓口

| チェーン | TEL : 0120-251-664 | FAX : 0120-251-665 |

|---|

月曜日~金曜日 9:00~12:00 / 13:00~17:00

(祝日・弊社休業日を除く)