技術資料 高速リフタ ジップチェーンリフタ 取扱

運転・点検手順

ここでは、ジップチェーンリフタに関する一般的取扱いについて記載しています。

詳細につきましては、製品に同梱しています取扱説明書をご参照ください。

運転

- ・三相モータに仮配線ケーブル(動力用、ブレーキ用)が取り付けられています。ジップチェーンリフタ初動時は、取り付けられているケーブルを使用して仮配線を行い、天板フレームを上昇させた後に、本配線を行ってください。決して仮配線ケーブルを本配線に使用しないでください。

- ・ジップチェーンリフタは、許容荷重、許容昇降速度を必ず守ってお使いください。これを超えると本体が破損する恐れがあります。

- ・いかなる場合でも惰走も含めてストロークを逸脱する範囲では絶対に使用しないでください。逸脱すると装置が破損する恐れがあります。リフタには、いかなるときでも衝撃を与えないでください。

- ・ジップチェーン、可動部、検出部などには、粉塵や切粉などの異物が付着もしくは混入しないようにしてください。これらは摩耗を促進し、チェーンの破断や、可動部の破損など重大な事故に繋がります。リフタ本体に異物が侵入しないように必ず対策してください。

さらにリフタの周囲に安全柵を設け、上面フレーム下の空間に立ち入ることができないようにしてください。 - ・停止時には負荷が落下しないよう、必ずモータの保持ブレーキが作動するようにシーケンス回路を設計してください。

- ・いかなる場合も当て止めは、行わないでください。当て止めを行いますと製品内部に重大な損傷を起こす恐れがあります。

- ・装置は高温となる箇所があります。手や体を触れないようにご注意ください。やけどの恐れがあります。

- ・異常が発生した場合は直ちに運転を停止してください。感電、けが、火災の恐れがあります。

- ・緊急時に停止させる場合であっても、サーボモータ内蔵のメカブレーキによる制動はしないでください。必ず、ダイナミックブレーキによる減速後にメカブレーキが作動するような制御ロジックとしてください。詳細は、モータメーカの取扱説明を参照してください。

点検手順

1. 保守点検時の安全確保(メンテナンスバーの使用)

保守・点検時に、止むを得ず天板フレーム下の空間に身体または身体の一部を入れなければならない場合、必ずメンテナンスバーをセットしてください。

落下防止措置を怠ると、死亡などの重大な人身事故発生の恐れがあります。

作業はリフタ上面のすべての搬送物を取り除いてから行ってください。

運転再開時には、機体内部にメンテナンスバーが残っていないことを必ず確認ください。

※メンテナンスバーは絶対に改造しないでください。改造は重大な事故に繋がる恐れがあります。

なお、クレーンなどで天板フレームを吊り下げると、2重の安全対策となります。

2. ジップチェーンの点検(1ヵ月毎)

- (1)搬送物を取り除いてください。

- (2)落下防止措置を実施し、昇降部の落下が起こらないようにしてください。

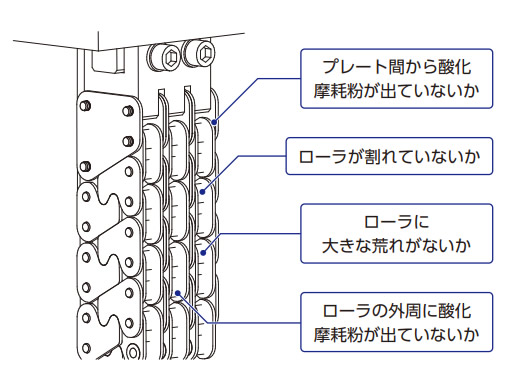

- (3)ジップチェーン全長で、以下のことを確認してください。

- ・プレート間から酸化摩耗粉(赤茶色)が出ていないか

- ・チェーンローラ外周に酸化摩耗粉(赤茶色)が出ていないか

上記の場合は、直ぐに給脂してください。 - ・チェーンローラが割れていないか

- ・チェーンローラを触診し、摩耗による大きな荒れがないか

上記のいずれかがある場合、使用を中止し当社へご連絡ください。

3. 給脂

本製品の給脂の詳細については下表をご参照ください。

| 使用区分 | 給脂方法 | 推奨油脂名称 | 給脂サイクル |

|---|---|---|---|

| ジップチェーン | ストローク100mmあたり10~15g を目安に刷毛塗り |

高荷重用グリース1種2号相当品 シェル ガダス S2 V220 J 2 (EP) ※ [シェルルブリカンツジャパン(株)] |

3ヵ月または 10万往復毎 |

| ローラの走行レール | 適量を刷毛塗り | ||

| ローラ | 適量をグリースガンで塗布 |

※旧名称:シェルアルバニヤ EP グリース2

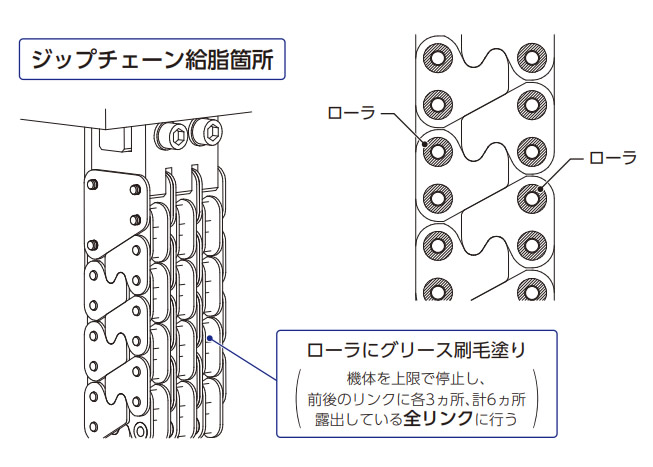

(ジップチェーンの給脂)

ジップチェーンの給脂は以下の手順で行ってください。

- [1]上面フレーム上の全ての搬送物を取り除いてください。

- [2]落下防止措置を実施し、昇降部の落下が絶対起こらないようにしてください。

- [3]右図のとおり、露出している全てのローラに給脂してください。

(走行レール・ローラ部の給脂)

レールの走行面(上下面とも)にグリースを塗布してください。

給脂後は慣らし運転を実施し、余分なグリースは除去してから運転を開始してください。