技術資料 高速リフタ ジップマスタ 選定

検討時の注意点

1. 加減速時間について

- ・ジップマスタは昇降速度が速いため、インバータ制御を必須とし、十分な加減速時間を設けてご使用ください。

急加速・急停止しますと停止精度の悪化やワークの振動が発生する場合があります。

据付面・アームの剛性や荷重条件により、起動停止時にジップマスタが振れる場合は加減速時間を長く取ってご使用ください。

また、振れ量を軽減させる場合はジップマスタ上部の固定をご検討ください。 - ・ジップマスタの速度は最大速度です。昇降時間を求める場合は加減速時間を含めて計算してください。

- ・昇降時間の短縮・高頻度運転・多点位置決め・連動運転などが必要な場合はサーボモータ付をお奨めします。

ご要望のサーボモータメーカに対応しますのでご相談ください。

2. インバータ制御について

- ・下降時には大きな回生電流が発生しますので、ご使用条件にもとづき十分なインバータ回生抵抗器の容量を設けてください。

回生抵抗器の容量についてはインバータメーカへご相談願います。 - ・インバータはモータに対して1枠大きい容量のご使用を推奨します。

- ・インバータトリップ時にはブレーキが作動するシーケンスを組んでください。

3. 落下防止について

- ・ジップマスタは無励磁作動形ブレーキ付モータを採用しています。サーボモータ仕様として貴社にてモータをご用意される場合はブレーキ付キー溝軸仕様を採用ください。

また、万が一の落下に備えお客様にて落下防止機構をご用意ください。また、当社でも落下防止用ピンを特形対応として製作可能です。

4. サーボモータ制御について

- ・下降時には大きな回生電流が発生しますので、ご使用条件にもとづき十分な回生抵抗器の容量を設けてください。

回生抵抗器の容量についてはサーボモータメーカへご相談願います。 - ・緊急時に停止させる場合であっても、モータ内蔵のメカブレーキによる制動はしないでください。

必ず、ダイナミックブレーキによる減速後にメカブレーキが作動するような制御ロジックとしてください。詳細は、モータメーカの取扱説明を参照してください。

選定について

選定に必要な使用条件

- 1. 使用装置と必要台数

- 2. 昇降物質量

- 3. 速度

- 4. ストローク

- 5. 負荷のオーバハング量

- 6. 使用頻度

- 7. 使用環境

詳しくはジップマスタテクニカルシート(こちら)をご覧ください。

選定手順

- 1. 使用機械、使用方法、使用環境がジップマスタに適しているか確認します。

- 2. 昇降荷重を満足する定格荷重を持つ形番を仕様一覧(こちら)より選択します。

※定格荷重を超える昇降荷重の場合は複数連動運転をご検討ください。

複数連動運転の選定・制御方法はご相談ください。また、高負荷仕様も特形として対応しますのでご相談ください。 - 3. 昇降速度は選択形番の速度で満足するか確認します。

※昇降速度を上げた仕様も対応しますのでご相談ください。 - 4.必要なストロークを確認します。

※ストローク2mを超える場合は特形として対応しますのでご相談ください。 - 5. 選定形番の許容オーバハングロードが満足するか下記を参照に確認します。

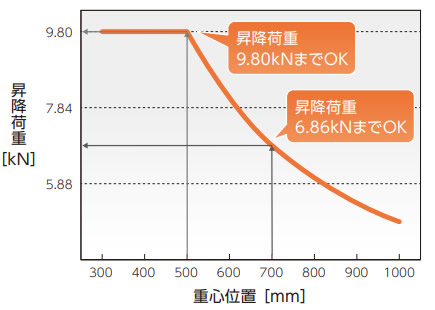

許容オーバハングロード(OHL)の確認

昇降荷重と重心位置を確認すれば、簡単にジップマスタが選定できます。右図のように、昇降荷重と重心位置の交点が許容オーバハングロード値となります。

各形番毎のオーバハングロード荷重曲線(こちら)をご覧ください。

注意

- ・アームに荷重が掛かると、ジップマスタは荷重方向に歪み、アーム先端が水平より下がることを見込むことが必要です。歪み量はジップマスタのストロークが長いほど大きくなるだけでなく、アーム・据付面の剛性にも影響します。

- ・歪み量や起動停止時の振れ量を軽減させる場合はジップマスタ上部の固定をご検討ください。

- ・ジップマスタの歪み量についての詳細は別途お問合せください。

ZMEL1000M

(ワーク取付面基準:外形図参照)

ZMEL1000Mの場合

例1 重心位置が500mmの時、昇降は荷重9.80kNまで可能です。

例2 重心位置が700mmの時、昇降は荷重6.86kNまで可能です。