技術資料 パワーロック 注意事項

KE・KE-KP・KE-SS・KE-LPシリーズ

1. 溝付軸への取付け

モータ軸などのように、すでにキー溝加工などをした軸にパワーロックを取付ける場合は、伝達トルクMtおよびスラスト荷重Paxは10%減少します。

- 伝達トルク:Mt × 0.9

- スラスト荷重:Pax × 0.9

2. 取付精度

パワーロックのストレート穴のボスに取付けたとき、ボスの取付精度は下記を目安にする値となります。

(ボス長さが、ボスとアウタリングの接触面幅と同一の場合)

- Ex:ボス端面の振れ量 0.002 × r mm以下

- Er:ボス外径の振れ量 0.05mm以下

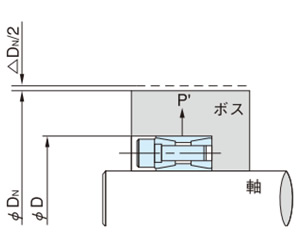

3. ボス外径の変形

パワーロックをボスに取付けると、ボス内径面に面圧P'が作用するため、ボスの外径に弾性変形が発生します。

この変形量は面圧P'のバラツキ、ボスの形状等により正確に求めることはできませんが、目安としては次式により算出することができます。

△DN ≒ DN E × 2 × K3 × P' ( DN D ) 2 - 1

- P':ボス側面圧 MPa

- E:ヤング率 鉄鋼の場合 E = 205800 MPa

- D:ボス内径 mm

- DN:ボス外径 mm

- △DN:ボス外径変形量 mm

- K3:ボス形状係数

(各製品の主要諸元ページを参照ください。)

4. 周囲温度

パワーロックの性能を十分生かす使用場所の周囲温度は-30℃~200℃の範囲でご使用ください。

5. 締付トルクMAの許容値

締付ボルトの締付トルクMAの許容値は±5%です。

この値は伝達トルクMtおよびスラスト荷重Paxを十分保証しうるもので、トルクレンチの適正使用において考えられる誤差は十分吸収されます。

6. 組付け時のオイル・グリース塗布の必要性について

パワーロックを組付けする際、本体部および締付ボルトに塗油することはとても重要です。

油分を塗布することでパワーロックが滑るのではないか、締付ボルトが緩むのではないかと思われがちですが、ボルトの締付トルクは潤滑状態での効率で計算されていますし、テーパ面のスムーズな移動にも油分は不可欠です。

逆に、油分を塗布しなければ、軸力の低下により伝達トルクは約25%低下し、また締付ボルトのカジリなど不具合の原因にもなりますので、脱脂などは絶対に行わないでください。

尚、ステンレス仕様・無電解ニッケルメッキ仕様については締付ボルトに特殊潤滑コーティングを施し、本体もドライ状態での使用を前提にしていますので、組付け時のオイル・グリースの塗布はしないでください。

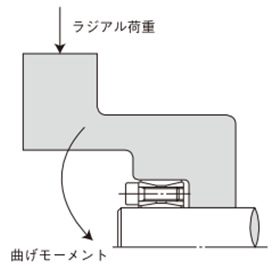

7. 曲げモーメント

パワーロックは原則として曲げモーメントを受けることはできません。下図に示すように曲げモーメントが作用する場合は当社までご相談ください。

8. 屋外での使用

水滴、雨水などにさらされても、パワーロックの取付接触面は高面圧のために水の浸入はないので、性能の低下はありません。

しかし、接触面を除き、錆が発生します。特にボルトは大きな張力が作用していますので錆の発生により強度が低下し、締結力も極端に低下して、破断することがあります。

これを防ぐため、パワーロックをカバーでおおい、グリースを充填して防錆処置を行ってください。

カバーが取付けられない場合はステンレス仕様や無電解ニッケルメッキ仕様をご使用ください。