技術資料 電気式制御機器 ショックモニタ

トルク監視について

基本形の場合、パラメータ19の[POWER/TORQUE]をTORQUEに設定しますとトルク演算値による監視ができます。

トルク監視では、予め設定した過負荷レベル(=トルクの%で設定)とトルク演算値(%)を比較します。

インバータ運転で任意に周波数が変わる場合にたいへん便利な機能です。

1. トルク演算式

ショックモニタのトルク監視では、「検出した電力(%)」、「モータ供給電圧の周波数」および「推定モータ銅損(%)」の3つの要素から次の式でトルク値を演算しています。

(60Hz時のトルクを100%とします。)

トルク演算値(%) = (検出電力 - 推定モータ銅損) × 60 周波数

2. インバータ運転における電力監視とトルク監視の違い

インバータで変速運転する場合、負荷トルクが一定であっても周波数を半分にすれば仕事量は約半分となり、モータ消費電力も約半分となります。

電力監視の場合は、周波数を半分にした時は多段切り替え機能を使って過負荷検知レベルも約半分にしないと精度よく過負荷を捕らえることができません。

これに対し、トルク監視では、半分になった検出電力に対しショックモニタが読み取ったモータ供給電圧の周波数で割り算することにより過負荷検知レベルの変更を不要にすることが可能となります。無段階の任意周波数で運転される場合にたいへん便利な機能です。

3. トルク監視でのご注意

- ・トルク演算値は60Hzにおける定格トルクを基準としています。

- ・トルク演算値の誤差を小さくするため、推定モータ銅損を減算した補正演算としていますが、特に低周波数(約20Hz以下)にて使用される場合は上式の検出電力が小さくなる上、分母の周波数が小さくなるため誤差が非常に大きくなり注意が必要です。

4. 各周波数におけるトルク演算値

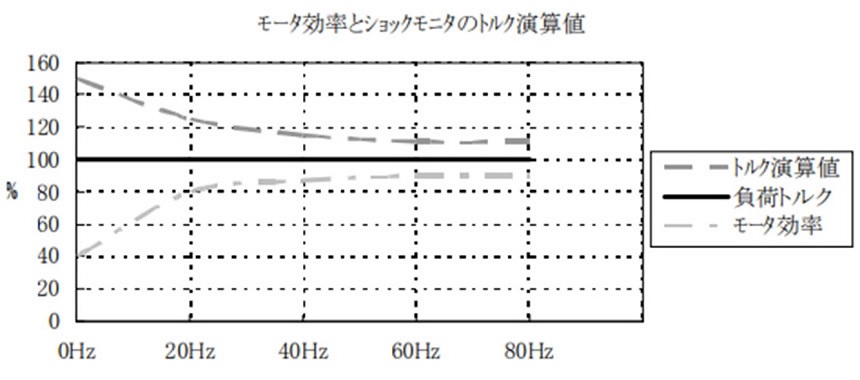

モータ効率は、低周波数で非常に悪くなるため、下図のようにショックモニタのトルク演算値の誤差が大きくなります。

図のように、低い周波数でトルク監視を行った場合、トルク演算値が大きくなり出力リレーが動作しやすくなります。

位置決め運転等で、20Hz以下にされる場合は低速周波数を固定すると共に多段設定の併用を推奨します。