技術資料 カップリング 取扱

ナイロンチェーンカップリング 取扱

標準タイプおよびEタイプのチェーン(ポリアセタール樹脂)は低温雰囲気で継手ピンの取付け・取外しを行うと破損する場合があります。

継手ピンの取付け・取外しは、必ず周囲温度が10℃以上の雰囲気、もしくはドライヤーなどで継手部を部分的に温めてから行ってください。

取付け

-

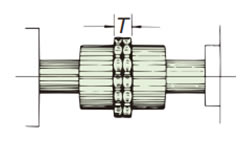

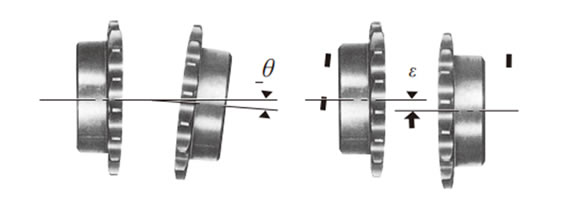

1. スプロケットの側面を密着させ偏角(角度誤差)を修正します。歯の側面の長さTが外周で等しくなるように角度を修正します。

-

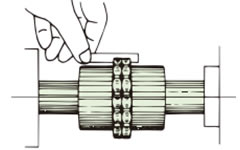

2. スプロケットの側面を密着させ偏心(平行誤差)を修正します。歯面にストレートなものを当て、歯底の食い違いを無くします。

-

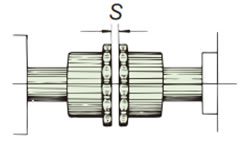

3. 両スプロケットの間をS寸法にし、チェーンを巻き付けます。

-

4. 継手ピンをチェーンの穴部に挿入し、ピンに偏荷重がかからないよう真直ぐ差込み、チェーンを連結します。差込み時にピンが変形した場合は、そのピンを取除き、予備のピンにて再度取付けを行なってください。

チェーンを連結後、セットボルトなどでスプロケットを軸に固定します。

| タイプ | 許容偏角 (角度誤差)θ |

許容偏心 (平行誤差)ε |

許容エンドプレイ (軸方向変位)S |

|---|---|---|---|

| 標準タイプ | 0.5° | 0.1mm | 寸法表を参照ください |

[使用可能温度雰囲気]

標準タイプ:-5℃~+60℃

[使用上のご注意]

万一当社カップリングのチェーンが破損した場合でも、破片が飛散しないような安全カバーを、貴社にて別途装備されることをおすすめします。

取外し

- 1. まず、カップリングにトルクがかかっていないことを確認してください。

- 2. 確認後、チェーンの任意の1ヵ所のピン(どのピンでもよい)を抜いてチェーン、スプロケットを取外してください。