技術資料 小形コンベヤチェーン 取扱

使用限度

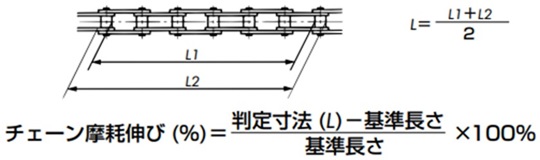

1. チェーンの摩耗伸び

チェーン全体のガタを除くために、ある程度チェーンを張った状態でチェーン長さを測定します。測定誤差を少なくするために6~10リンクのローラの内側(L1)と外側(L2)を計り、判定寸法(L)を求めます。

基準長さ = 称呼チェーンピッチ × 測定リンク数

チェーンの摩耗伸びが2%以上の時は取替えてください。

※ピッチ伸び限界が一目で確認できるチェーン摩耗測定スケールもご覧ください。

ラムダチェーンは、チェーン伸びが0.5%位になったとき、油切れになることがあります。油切れの目安として、プレート間に赤い摩耗粉が付き、屈曲不良も発生します。

このときが寿命です。

2. Rローラ

ローラ外周部、およびブシュとの摺動部分の摩耗によってプレートの下面がガイドレールに当たり始めると寿命です。

プレートがガイドレールに当たり始めると、摩擦抵抗が大きくなりチェーンに作用する張力の増大、モータ出力の不足などの原因になります。

3. Sローラ

摩耗によってローラに穴があいたり、割れを生じた時には寿命です。

4. プレート

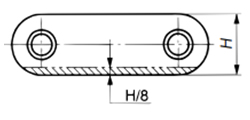

プレートが直接搬送物、あるいはガイドレールの上を滑っている場合には、図のようにプレートのH寸法が1/8位摩耗すると限度です。

図30. プレート幅の摩耗

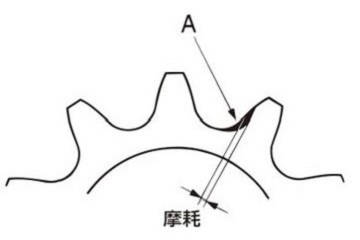

5. スプロケット

スプロケットが下図(左)のように摩耗してくると、A部にチェーンが引っ掛かって離れが悪くなり、チェーンが振動を起します。

摩耗の許容量はコンベヤの形式、チェーンのサイズによって多少異なりますが0.3mm~1.0mm位摩耗したところで、取替えますとチェーンをいためずにすみます。

また、スプロケットが下図(右)のように歯幅方向に摩耗する場合は、軸の心出しが不正確ですので修正してください。

図32. スプロケット歯の摩耗