RS® ローラチェーン BS/DIN規格 主要諸元

RS48B-3

| ※ | CADデータはキャデナス・ウェブ・ツー・キャド(株)のCAD図面ライブラリーサイト「PARTcommunity」へのリンクにより提供いたします。 |

| ※ | CADデータ及びPARTcommunityのお問い合わせにつきましてはキャデナス・ウェブ・ツー・キャドまでご連絡ください。 【キャデナス・ウェブ・ツー・キャド株式会社】TEL: (03)5961‐5031 FAX: (03)5961‐5032 |

カタログ・取扱説明書

形番表示例

| RS48B | - | 3 | - | RP | + | 182L | - | MCJ | R | - | P |

| | サイズ |

| 列数 |

| | | |

| リンク数 |

| | | | | |

| | | |

| オプション記号 |

|||||

| 本体ピン形式 |

反対側端末 |

||||||||||

| 端末 |

|||||||||||

主要諸元

| サイズ& 列数 |

JIS番号 | 列数 | 最小引張強さ kN {kgf} |

ISO606引張強さ kN {kgf} |

最大許容張力 kN {kgf} |

概略質量 kg/m |

ユニットの リンク数 |

|---|---|---|---|---|---|---|---|

| RS48B-3 | 48B | 3 | 1520{155000} | 1500{153000} | 193{19700} | 75.00 | 40 |

注記

1.継手リンク(JL)をご使用の場合の最大許容張力は上表の80%になります。

2.1ピッチ、2ピッチオフセットリンク(OL,2POL)をご使用の場合の最大許容張力は上表の60%になります。

3.都度見積品です。

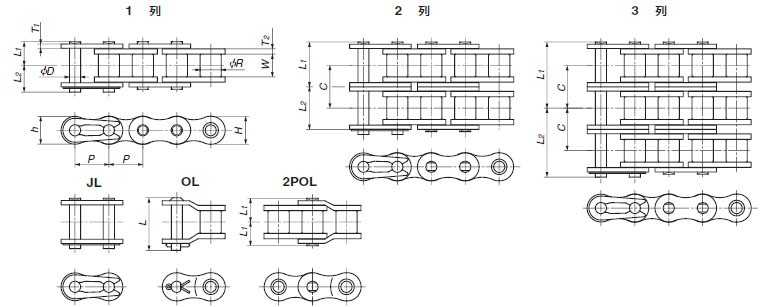

主要寸法 mm

| ピッチ P |

ローラ径 R |

内リンク内幅 W |

プレート | ピン | 横ピッチ C mm |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| T1 | T2 | H | h | D | L1 | L2 | L | ||||

| 76.2 | 48.26 | 45.72 | 10.0 | 12.1 | 63.8 | 59.8 | 29.23 | 140.6 | 150.0 | 300.2 | 91.21 |

注記

1.外プレート厚さは単列チェーンの値です。多列チェーンは横ピッチ寸法の関係で異なる場合があります。

適用継手リンク

| タイプ | 継手リンク | オフセットリンク | 2ピッチ オフセットリンク |

|---|---|---|---|

| 形番 | RS48B-3-MWJL | RS48B-3-OL | RS48B-3-2POL |

| 希望価格(税別) | お問合せください | お問合せください | お問合せください |

| 納期 | お問合せください | お問合せください | お問合せください |

伝動能力表 kW (多列係数2.5乗算済み)

| 小 スプロケット 歯数 |

小スプロケット回転速度 r/min | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 80 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 350 | 400 | 450 | |

| 潤滑形式AI | 潤滑形式AII | 潤滑形式B | 潤滑形式C | |||||||||||||||||

| 9 | 8.38 | 15.6 | 22.5 | 29.3 | 35.8 | 42.0 | 54.5 | 66.5 | 78.5 | 101 | 124 | 151 | 178 | 190 | 196 | 201 | 198 | 188 | 172 | 151 |

| 10 | 9.38 | 17.5 | 25.3 | 32.8 | 40.0 | 47.0 | 61.0 | 74.5 | 87.8 | 113 | 139 | 170 | 200 | 210 | 216 | 221 | 217 | 205 | 188 | 164 |

| 11 | 10.4 | 19.4 | 28.0 | 36.3 | 44.3 | 52.3 | 67.5 | 82.5 | 97.3 | 126 | 154 | 188 | 219 | 229 | 236 | 241 | 236 | 222 | 202 | 176 |

| 12 | 11.4 | 21.3 | 30.8 | 39.8 | 48.8 | 57.3 | 74.3 | 90.8 | 107 | 138 | 169 | 207 | 237 | 248 | 255 | 260 | 255 | 239 | 216 | 187 |

| 13 | 12.5 | 23.3 | 33.5 | 43.5 | 53.0 | 62.5 | 81.0 | 99.0 | 116 | 151 | 184 | 225 | 255 | 267 | 275 | 280 | 272 | 255 | 230 | 197 |

| 14 | 13.5 | 25.3 | 36.3 | 47.0 | 57.5 | 67.8 | 87.8 | 107 | 126 | 163 | 200 | 244 | 272 | 285 | 292 | 297 | 287 | 270 | 242 | 207 |

| 15 | 14.6 | 27.3 | 39.0 | 50.8 | 62.0 | 73.0 | 94.5 | 115 | 136 | 176 | 215 | 262 | 290 | 302 | 310 | 315 | 305 | 285 | 255 | 215 |

| 16 | 15.6 | 29.0 | 42.0 | 54.3 | 66.3 | 78.3 | 101 | 123 | 146 | 189 | 231 | 282 | 307 | 320 | 330 | 332 | 320 | 297 | 265 | 223 |

| 17 | 16.7 | 31.0 | 44.8 | 58.0 | 70.8 | 83.5 | 108 | 132 | 155 | 201 | 246 | 302 | 325 | 337 | 345 | 350 | 337 | 312 | 275 | 230 |

| 18 | 17.7 | 33.0 | 47.5 | 61.8 | 75.3 | 88.8 | 115 | 140 | 165 | 214 | 262 | 320 | 340 | 355 | 362 | 365 | 352 | 325 | 285 | 236 |

| 19 | 18.8 | 35.0 | 50.5 | 65.3 | 80.0 | 94.3 | 122 | 149 | 175 | 227 | 277 | 335 | 357 | 372 | 380 | 380 | 365 | 335 | 295 | 241 |

| 20 | 19.8 | 37.0 | 53.3 | 69.0 | 84.5 | 99.5 | 129 | 157 | 185 | 240 | 295 | 352 | 372 | 387 | 395 | 397 | 380 | 347 | 302 | 246 |

| 21 | 20.9 | 39.0 | 56.3 | 72.8 | 89.0 | 105 | 136 | 166 | 195 | 252 | 310 | 367 | 390 | 405 | 412 | 412 | 392 | 357 | 310 | 250 |

| 22 | 22.0 | 41.0 | 59.0 | 76.5 | 93.5 | 110 | 143 | 174 | 205 | 267 | 325 | 382 | 405 | 420 | 427 | 425 | 405 | 367 | 315 | 252 |

| 23 | 23.1 | 43.0 | 62.0 | 80.3 | 98.3 | 115 | 150 | 183 | 216 | 280 | 342 | 397 | 420 | 435 | 442 | 440 | 417 | 377 | 322 | 255 |

| 24 | 24.2 | 45.0 | 65.0 | 84.0 | 102 | 121 | 157 | 191 | 226 | 292 | 357 | 410 | 435 | 450 | 457 | 455 | 427 | 385 | 327 | 255 |

| 25 | 25.3 | 47.0 | 67.8 | 88.0 | 107 | 126 | 164 | 200 | 236 | 305 | 375 | 425 | 450 | 465 | 472 | 467 | 440 | 392 | 332 | 255 |

| 26 | 26.3 | 49.3 | 70.8 | 91.8 | 112 | 132 | 171 | 209 | 246 | 320 | 390 | 440 | 465 | 480 | 487 | 480 | 450 | 400 | 335 | 255 |

注記

1.1ピッチ形オフセットリンクを使用する場合、伝動能力は表記値の80%になります。

2.伝動能力表の灰色着色部分でご使用の場合は当社にご相談ください。

| 潤滑形式 | AI | AII | B | C | |

|---|---|---|---|---|---|

| 方法 | 油差し | 滴下給油 | 油浴、または回転板による潤滑 | 強制ポンプ潤滑 |

ホームページからのお問い合わせ/資料請求

製品お問い合わせ

各製品へのお問い合わせ及び製品カタログ・資料請求はこちらより承っております。

ご利用の際は当サイトの会員登録をお願いします。

【お問い合わせ】 |

【資料請求】 |

|---|

各種証明書の発行について

一部の証明書は弊社製造番号と紐づけて発行しております。

以下についてはご購入先を通じてご依頼ください。

・該非判定書

・EAR判定書

・原産地証明書

見積依頼、納期確認について

弊社では直接販売をしておりません。

購入価格・納期に関するお問い合わせはお取引のある商社様を通じてご確認ください。

購入先をお探しのお客様は取扱販売店一覧をご覧ください。

お問い合わせ窓口

製品窓口

| チェーン | TEL : 0120-251-664 | FAX : 0120-251-665 |

|---|

月曜日~金曜日 9:00~12:00 / 13:00~17:00

(祝日・弊社休業日を除く)