技術資料 カップリング 取扱

ジョーフレックスカップリング LNシリーズ 取扱

心出し

カップリングの最初の心出し精度が高ければ高い程、使用中に発生する偏心回転応力を抑えることができます。

軸受の摩耗、据付面の沈下、温度による状態変化、振動等による使用中の変化が、お客様の機器とカップリングの寿命を短くすることになります。定期的に調整を行ってください。

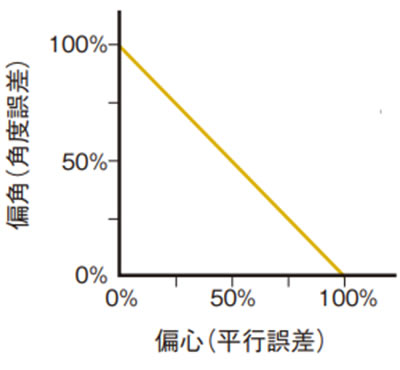

カップリングの許容偏角(角度誤差)、偏心(平行誤差)は相関関係にあり、一方が増加すると一方が減ずるため同時に考慮する必要があります。

| 形番 | スパイダー 硬度 |

許容ミスアライメント | ||

|---|---|---|---|---|

| 偏角(角度誤差) deg |

偏心(平行誤差) mm |

エンドプレイ (軸方向変位) mm |

||

| LN24 | 98A | 0.9 | 0.10 | -0.5~+1.4 |

| 64D | 0.8 | 0.07 | ||

| LN28 | 98A | 0.9 | 0.11 | -0.7~+1.5 |

| 64D | 0.8 | 0.08 | ||

| LN38 | 98A | 0.9 | 0.12 | -0.7~+1.8 |

| 64D | 0.8 | 0.09 | ||

偏角(角度誤差)と偏心(平行誤差)は他方のミスアライメントが0の時の値です。

偏角(角度誤差)と偏心(平行誤差)の関係

使用環境

スパイダーは、空気中の水分、大気ガス、熱、紫外線などの影響を受け、時間経過とともに少しずつ劣化が進行しますので、ご使用環境にご注意ください。

周囲温度-30℃~80℃のなるべく風通しの良いほこりや湿気の少ない所で使用してください。

腐食性の液体やガスのある場所、引火性・爆発性のある場所でのご使用は避けてください。

耐水性・耐食性はありませんので、屋外でのご使用は避けてください。

点検

実際の運転に入って1~2時間後に、偏角(角度誤差)と偏心(平行誤差)を再チェックしてください。

また、定期的(例えば半年~1年毎)に部品の異常やスパイダーの摩耗を確認してください。

スパイダーは消耗品です。定期的に交換をしてください。