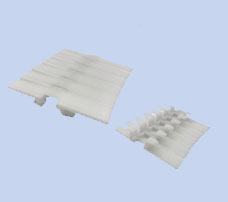

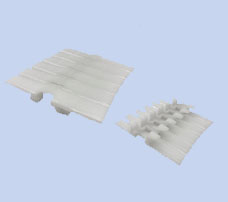

Plastic top chain TPUMF-T/TPUMF-TB type

- Chain pitch

19.05mm - Sideflexing

- Effective in saving the space in transfer section by adopting a chain pitch of 19.05mm, which is 1/2 of conventional TPU type (chain pitch of 38.1 mm).

- Chain with float-preventive attachments (tabs)

- Prevents the chain from floating on corner section and ascending/descending conveyors, and scratches on top surface of plate on return side.

Features

-

・Chain can be selected according to conveying conditions

Features Sideflexing running chain with a flat conveying surface Three convex shapes of the conveying surface suppress the conveyed material from sliding down In combination with TPUMF-T and TPUMF-TB types, inclined conveyance with flight links is possible. Model TPUMF1200-T

TPUMF1200-TB

TPUMF1200F-T

Application examples

- Note )1.Plate top surface of TPUMF1200-TB is mirror surface finish without texture.

- 2.Plate top surface and flight of TPUMF1200F-T are mirror surface finish without texture.

-

・Shorter pitch reduces transit space.

The chain pitch is 19.05mm, which is 1/2 of the conventional TPU chain pitch.

The dead space is small due to the in-line layout, enabling smooth transfers.

-

・Prevents the chain from floating and scratches on the conveying surface with float-preventive attachments (tabs).

Prevents the chain from floating on corner section and ascending/descending conveyors with float-preventive attachments (tabs).

In addition, prevents scratches on conveyor surface by hanging float-preventive attachment (tabs) on return side, making it ideal for conveying food.

-

・D-pin is used for connecting pin to prevent pin hole cracks

Connecting pin has a D-shaped cross-section and two protrusions to prevent it from falling out.

This protrusion hooks inside the pin hole of base chain link and prevents the pin from falling out.

D-pin and chain pin hole are loose fit to prevent fitting stress in a pin hole of base chain link and to prevent cracking.

-

・Conforms to the Food Sanitation Act (Ministry of Health and Welfare Notification No. 370)

Standard (W) series and Low-friction/Wear-resistant (LFG) series comply with the Food Sanitation Act (Ministry of Health and Welfare Notification No. 370).

Standard (W) series uses FDA (US Food and Drug Administration) approved materials.

■Application

The following are the industries we recommend.

May not be used depending on conveying capacity (conveyor speed), material to be conveyed (weight, shape), environment and application.

Use as a guide when selecting.

Contact us if there are any applications or conditions not described.

Recommended industry /Conveyed material size (●:Recommended ○:Can be used △:Varies depending on conveying conditions. )

| Conveying size (Weight ) |

Industry | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Can manufacturing | Beverages | Tire | Mechanical parts | Logistics | Pharmaceuticals | Bakery/Food | Secondary battery | Semiconductor ・ Solar panel related |

|

| High | △ | ||||||||

| Medium | △ | △ | △ | △ | ○ | ||||

| Low | ○ | ○ | ○ | ○ | ● | ||||

Application

- ■Noodle production line

Note )1.In case of using chains for food direct conveyance, it is necessary to acquire detailed information of the usage and to provide the safety confirmation sheet in compliance with the Product Liability Act.

2.Application example is an image.

List of Models

※Click "model" for more information

| Chain pitch mm | 19.05 | ||

|---|---|---|---|

| Application | Sideflexing | ||

| Chain type | - | ||

| - | |||

| Base chain specifications | - | ||

| Pin type | Stainless steel pin type | ||

| Pin material | SUS304 | ||

| Pin shape | D-shaped pin | ||

| Top plate thickness mm | 3.5 | ||

| Material of the pusher | - | ||

| Other functions | With float-preventive tabs | With float-preventive attachments (tabs) Links with flight |

|

| Model | TPUMF1200-T | TPUMF1200-TB | TPUMF1200F-T |

|

|

|

|

| Top plate width mm | 120 | ||