Ultra PX Belt HA Type (Oil proof/Water proof type) Major Specifications

Model No. :UP8M25-HA

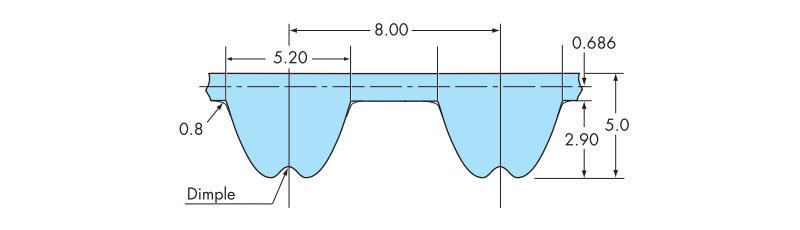

PDF Outline Drawing

See the table below

DXF drawings / 3D CAD data

Major Specifications

| Belt width | Unit mass g/(mm width x m length) |

Initial tension N {kgf} | |

|---|---|---|---|

| Recommended value | Maximum value | ||

| 25 | 4.7 | 317 {32.3} | 421 {42.9} |

| Material | Rubber | High strength synthetic rubber (Oil Proof Type) |

|---|---|---|

| Tooth fabric | Nylon with superior wear-resistance | |

| Cord | High strength glass fiber | |

| Ambient conditions | Oil and water resistant | Can be used in contact with oil and water (including water-soluble coolant). |

| Available for the following belt sprocket types | PX Belt Sprocket P8M | |

| Operating Ambient Temperature | 0℃~60℃(When in contact with oil ) | |

| RoHS compliant | Compliant | |

| Electroconductive | None |

※Can be used in heat resistant applications. Contact a Tsubaki representative for more information.

Belt length

| Model No. | Circumference mm | Number of teeth | Standard Price | Delivery | PDF drawing |

|---|---|---|---|---|---|

| BG480UP8M25-HA | 480 | 60 | Contact us for details. | Contact us for details. | |

| BG512UP8M25-HA | 512 | 64 | Contact us for details. | Contact us for details. | |

| BG520UP8M25-HA | 520 | 65 | Contact us for details. | Contact us for details. | |

| BG536UP8M25-HA | 536 | 67 | Contact us for details. | Contact us for details. | |

| BG560UP8M25-HA | 560 | 70 | Contact us for details. | Contact us for details. | |

| BG576UP8M25-HA | 576 | 72 | Contact us for details. | Contact us for details. | |

| BG584UP8M25-HA | 584 | 73 | Contact us for details. | Contact us for details. | |

| BG600UP8M25-HA | 600 | 75 | Contact us for details. | Contact us for details. | |

| BG616UP8M25-HA | 616 | 77 | Contact us for details. | Contact us for details. | |

| BG632UP8M25-HA | 632 | 79 | Contact us for details. | Contact us for details. |

| Model No. | Circumference mm | Number of teeth | Standard Price | Delivery | PDF drawing |

|---|---|---|---|---|---|

| BG640UP8M25-HA | 640 | 80 | Contact us for details. | Contact us for details. | |

| BG656UP8M25-HA | 656 | 82 | Contact us for details. | Contact us for details. | |

| BG680UP8M25-HA | 680 | 85 | Contact us for details. | Contact us for details. | |

| BG688UP8M25-HA | 688 | 86 | Contact us for details. | Contact us for details. | |

| BG712UP8M25-HA | 712 | 89 | Contact us for details. | Contact us for details. | |

| BG720UP8M25-HA | 720 | 90 | Contact us for details. | Contact us for details. | |

| BG752UP8M25-HA | 752 | 94 | Contact us for details. | Contact us for details. | |

| BG760UP8M25-HA | 760 | 95 | Contact us for details. | Contact us for details. | |

| BG776UP8M25-HA | 776 | 97 | Contact us for details. | Contact us for details. | |

| BG800UP8M25-HA | 800 | 100 | Contact us for details. | Contact us for details. |

| Model No. | Circumference mm | Number of teeth | Standard Price | Delivery | PDF drawing |

|---|---|---|---|---|---|

| BG816UP8M25-HA | 816 | 102 | Contact us for details. | Contact us for details. | |

| BG824UP8M25-HA | 824 | 103 | Contact us for details. | Contact us for details. | |

| BG832UP8M25-HA | 832 | 104 | Contact us for details. | Contact us for details. | |

| BG840UP8M25-HA | 840 | 105 | Contact us for details. | Contact us for details. | |

| BG848UP8M25-HA | 848 | 106 | Contact us for details. | Contact us for details. | |

| BG856UP8M25-HA | 856 | 107 | Contact us for details. | Contact us for details. | |

| BG880UP8M25-HA | 880 | 110 | Contact us for details. | Contact us for details. | |

| BG896UP8M25-HA | 896 | 112 | Contact us for details. | Contact us for details. | |

| BG912UP8M25-HA | 912 | 114 | Contact us for details. | Contact us for details. | |

| BG920UP8M25-HA | 920 | 115 | Contact us for details. | Contact us for details. |

| Model No. | Circumference mm | Number of teeth | Standard Price | Delivery | PDF drawing |

|---|---|---|---|---|---|

| BG936UP8M25-HA | 936 | 117 | Contact us for details. | Contact us for details. | |

| BG944UP8M25-HA | 944 | 118 | Contact us for details. | Contact us for details. | |

| BG960UP8M25-HA | 960 | 120 | Contact us for details. | Contact us for details. | |

| BG984UP8M25-HA | 984 | 123 | Contact us for details. | Contact us for details. | |

| BG1000UP8M25-HA | 1000 | 125 | Contact us for details. | Contact us for details. | |

| BG1032UP8M25-HA | 1032 | 129 | Contact us for details. | Contact us for details. | |

| BG1040UP8M25-HA | 1040 | 130 | Contact us for details. | Contact us for details. | |

| BG1056UP8M25-HA | 1056 | 132 | Contact us for details. | Contact us for details. | |

| BG1080UP8M25-HA | 1080 | 135 | Contact us for details. | Contact us for details. | |

| BG1096UP8M25-HA | 1096 | 137 | Contact us for details. | Contact us for details. |

| Model No. | Circumference mm | Number of teeth | Standard Price | Delivery | PDF drawing |

|---|---|---|---|---|---|

| BG1120UP8M25-HA | 1120 | 140 | Contact us for details. | Contact us for details. | |

| BG1128UP8M25-HA | 1128 | 141 | Contact us for details. | Contact us for details. | |

| BG1152UP8M25-HA | 1152 | 144 | Contact us for details. | Contact us for details. | |

| BG1160UP8M25-HA | 1160 | 145 | Contact us for details. | Contact us for details. | |

| BG1192UP8M25-HA | 1192 | 149 | Contact us for details. | Contact us for details. | |

| BG1200UP8M25-HA | 1200 | 150 | Contact us for details. | Contact us for details. | |

| BG1208UP8M25-HA | 1208 | 151 | Contact us for details. | Contact us for details. | |

| BG1216UP8M25-HA | 1216 | 152 | Contact us for details. | Contact us for details. | |

| BG1240UP8M25-HA | 1240 | 155 | Contact us for details. | Contact us for details. | |

| BG1248UP8M25-HA | 1248 | 156 | Contact us for details. | Contact us for details. |

| Model No. | Circumference mm | Number of teeth | Standard Price | Delivery | PDF drawing |

|---|---|---|---|---|---|

| BG1264UP8M25-HA | 1264 | 158 | Contact us for details. | Contact us for details. | |

| BG1280UP8M25-HA | 1280 | 160 | Contact us for details. | Contact us for details. | |

| BG1304UP8M25-HA | 1304 | 163 | Contact us for details. | Contact us for details. | |

| BG1320UP8M25-HA | 1320 | 165 | Contact us for details. | Contact us for details. | |

| BG1344UP8M25-HA | 1344 | 168 | Contact us for details. | Contact us for details. | |

| BG1352UP8M25-HA | 1352 | 169 | Contact us for details. | Contact us for details. | |

| BG1360UP8M25-HA | 1360 | 170 | Contact us for details. | Contact us for details. | |

| BG1400UP8M25-HA | 1400 | 175 | Contact us for details. | Contact us for details. | |

| BG1424UP8M25-HA | 1424 | 178 | Contact us for details. | Contact us for details. | |

| BG1440UP8M25-HA | 1440 | 180 | Contact us for details. | Contact us for details. |

| Model No. | Circumference mm | Number of teeth | Standard Price | Delivery | PDF drawing |

|---|---|---|---|---|---|

| BG1480UP8M25-HA | 1480 | 185 | Contact us for details. | Contact us for details. | |

| BG1520UP8M25-HA | 1520 | 190 | Contact us for details. | Contact us for details. | |

| BG1576UP8M25-HA | 1576 | 197 | Contact us for details. | Contact us for details. | |

| BG1600UP8M25-HA | 1600 | 200 | Contact us for details. | Contact us for details. | |

| BG1640UP8M25-HA | 1640 | 205 | Contact us for details. | Contact us for details. | |

| BG1680UP8M25-HA | 1680 | 210 | Contact us for details. | Contact us for details. | |

| BG1760UP8M25-HA | 1760 | 220 | Contact us for details. | Contact us for details. | |

| BG1800UP8M25-HA | 1800 | 225 | Contact us for details. | Contact us for details. | |

| BG1816UP8M25-HA | 1816 | 227 | Contact us for details. | Contact us for details. | |

| BG1888UP8M25-HA | 1888 | 236 | Contact us for details. | Contact us for details. |

| Model No. | Circumference mm | Number of teeth | Standard Price | Delivery | PDF drawing |

|---|---|---|---|---|---|

| BG1904UP8M25-HA | 1904 | 238 | Contact us for details. | Contact us for details. | |

| BG1960UP8M25-HA | 1960 | 245 | Contact us for details. | Contact us for details. | |

| BG2000UP8M25-HA | 2000 | 250 | Contact us for details. | Contact us for details. | |

| BG2032UP8M25-HA | 2032 | 254 | Contact us for details. | Contact us for details. | |

| BG2064UP8M25-HA | 2064 | 258 | Contact us for details. | Contact us for details. | |

| BG2104UP8M25-HA | 2104 | 263 | Contact us for details. | Contact us for details. | |

| BG2160UP8M25-HA | 2160 | 270 | Contact us for details. | Contact us for details. | |

| BG2240UP8M25-HA | 2240 | 280 | Contact us for details. | Contact us for details. | |

| BG2256UP8M25-HA | 2256 | 282 | Contact us for details. | Contact us for details. | |

| BG2304UP8M25-HA | 2304 | 288 | Contact us for details. | Contact us for details. |

| Model No. | Circumference mm | Number of teeth | Standard Price | Delivery | PDF drawing |

|---|---|---|---|---|---|

| BG2320UP8M25-HA | 2320 | 290 | Contact us for details. | Contact us for details. | |

| BG2400UP8M25-HA | 2400 | 300 | Contact us for details. | Contact us for details. | |

| BG2456UP8M25-HA | 2456 | 307 | Contact us for details. | Contact us for details. | |

| BG2496UP8M25-HA | 2496 | 312 | Contact us for details. | Contact us for details. | |

| BG2600UP8M25-HA | 2600 | 325 | Contact us for details. | Contact us for details. | |

| BG2712UP8M25-HA | 2712 | 339 | Contact us for details. | Contact us for details. | |

| BG2768UP8M25-HA | 2768 | 346 | Contact us for details. | Contact us for details. | |

| BG2800UP8M25-HA | 2800 | 350 | Contact us for details. | Contact us for details. | |

| BG2896UP8M25-HA | 2896 | 362 | Contact us for details. | Contact us for details. | |

| BG2944UP8M25-HA | 2944 | 368 | Contact us for details. | Contact us for details. |

| Model No. | Circumference mm | Number of teeth | Standard Price | Delivery | PDF drawing |

|---|---|---|---|---|---|

| BG3048UP8M25-HA | 3048 | 381 | Contact us for details. | Contact us for details. | |

| BG3200UP8M25-HA | 3200 | 400 | Contact us for details. | Contact us for details. | |

| BG3304UP8M25-HA | 3304 | 413 | Contact us for details. | Contact us for details. | |

| BG3440UP8M25-HA | 3440 | 430 | Contact us for details. | Contact us for details. | |

| BG3600UP8M25-HA | 3600 | 450 | Contact us for details. | Contact us for details. | |

| BG3920UP8M25-HA | 3920 | 490 | Contact us for details. | Contact us for details. | |

| BG4400UP8M25-HA | 4400 | 550 | Contact us for details. | Contact us for details. |

Standard transmission capacity kW (Multiplied by the 1.79 coefficient of width)

| Small belt sprocket rotation speed r/min |

Upper row: Number of teeth of small belt sprocket Lower row: Pitch diameter mm | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 22 | 24 | 26 | 28 | 30 | 32 | 34 | 36 | 38 | 40 | 44 | 48 | 50 | 56 | 60 | 64 | 72 | |

| 50.93 | 56.02 | 61.12 | 66.21 | 71.30 | 76.39 | 81.49 | 86.58 | 91.67 | 96.77 | 101.86 | 112.05 | 122.23 | 127.32 | 142.60 | 152.79 | 162.97 | 183.35 | |

| 20 | 0.21 | 0.23 | 0.25 | 0.26 | 0.28 | 0.30 | 0.34 | 0.35 | 0.37 | 0.39 | 0.42 | 0.48 | 0.51 | 0.55 | 0.62 | 0.68 | 0.73 | 0.85 |

| 40 | 0.37 | 0.41 | 0.46 | 0.50 | 0.53 | 0.57 | 0.62 | 0.66 | 0.69 | 0.75 | 0.78 | 0.87 | 0.96 | 1.02 | 1.16 | 1.25 | 1.37 | 1.59 |

| 60 | 0.51 | 0.57 | 0.62 | 0.68 | 0.75 | 0.80 | 0.87 | 0.93 | 1.00 | 1.05 | 1.12 | 1.27 | 1.39 | 1.44 | 1.66 | 1.79 | 1.95 | 2.25 |

| 100 | 0.80 | 0.89 | 0.98 | 1.07 | 1.16 | 1.27 | 1.34 | 1.43 | 1.53 | 1.64 | 1.73 | 1.93 | 2.14 | 2.25 | 2.59 | 2.81 | 3.04 | 3.50 |

| 200 | 1.41 | 1.57 | 1.75 | 1.89 | 2.07 | 2.23 | 2.39 | 2.57 | 2.75 | 2.93 | 3.13 | 3.47 | 3.86 | 4.06 | 4.65 | 5.08 | 5.49 | 6.39 |

| 300 | 1.98 | 2.20 | 2.43 | 2.66 | 2.88 | 3.11 | 3.34 | 3.59 | 3.84 | 4.09 | 4.34 | 4.86 | 5.40 | 5.69 | 6.55 | 7.12 | 7.71 | 9.00 |

| 400 | 2.48 | 2.75 | 3.04 | 3.34 | 3.61 | 3.93 | 4.22 | 4.52 | 4.85 | 5.17 | 5.49 | 6.17 | 6.87 | 7.21 | 8.28 | 9.03 | 9.80 | 11.4 |

| 500 | 2.95 | 3.27 | 3.63 | 3.97 | 4.31 | 4.68 | 5.06 | 5.42 | 5.81 | 6.19 | 6.58 | 7.39 | 8.21 | 8.64 | 9.97 | 10.8 | 11.8 | 13.7 |

| 600 | 3.40 | 3.77 | 4.17 | 4.58 | 4.99 | 5.40 | 5.83 | 6.26 | 6.69 | 7.14 | 7.60 | 8.53 | 9.50 | 10.0 | 11.5 | 12.6 | 13.6 | 16.0 |

| 700 | 3.83 | 4.26 | 4.70 | 5.15 | 5.62 | 6.08 | 6.56 | 7.05 | 7.55 | 8.05 | 8.59 | 9.64 | 10.7 | 11.2 | 13.0 | 14.2 | 15.5 | 18.1 |

| 800 | 4.24 | 4.72 | 5.19 | 5.71 | 6.22 | 6.74 | 7.28 | 7.82 | 8.37 | 8.95 | 9.52 | 10.7 | 11.9 | 12.5 | 14.5 | 15.8 | 17.2 | 20.2 |

| 900 | 4.61 | 5.13 | 5.69 | 6.22 | 6.78 | 7.37 | 7.98 | 8.55 | 9.18 | 9.79 | 10.4 | 11.7 | 13.1 | 13.8 | 15.9 | 17.4 | 18.9 | 22.2 |

| 1000 | 4.99 | 5.54 | 6.15 | 6.73 | 7.35 | 7.98 | 8.62 | 9.27 | 9.91 | 10.6 | 11.2 | 12.7 | 14.2 | 14.9 | 17.3 | 18.9 | 20.6 | 24.2 |

| 1100 | 5.37 | 5.99 | 6.62 | 7.28 | 7.94 | 8.62 | 9.30 | 10.0 | 10.7 | 11.4 | 12.2 | 13.7 | 15.3 | 16.1 | 18.7 | 20.5 | 22.3 | 26.2 |

| 1200 | 5.76 | 6.42 | 7.10 | 7.80 | 8.53 | 9.23 | 9.98 | 10.7 | 11.5 | 12.3 | 13.1 | 14.7 | 16.5 | 17.4 | 20.2 | 22.1 | 24.0 | 28.2 |

| 1300 | 6.12 | 6.83 | 7.55 | 8.32 | 9.05 | 9.86 | 10.6 | 11.4 | 12.2 | 13.1 | 13.9 | 15.7 | 17.6 | 18.6 | 21.5 | 23.6 | 25.7 | 30.2 |

| 1400 | 6.49 | 7.24 | 8.01 | 8.82 | 9.61 | 10.4 | 11.2 | 12.1 | 13.0 | 13.9 | 14.8 | 16.7 | 18.7 | 19.7 | 22.9 | 25.1 | 27.4 | 32.2 |

| 1450 | 6.67 | 7.44 | 8.25 | 9.05 | 9.89 | 10.7 | 11.6 | 12.5 | 13.4 | 14.3 | 15.3 | 17.2 | 19.3 | 20.3 | 23.6 | 25.9 | 28.3 | 33.2 |

| 1500 | 6.85 | 7.64 | 8.48 | 9.30 | 10.1 | 11.0 | 11.9 | 12.8 | 13.8 | 14.7 | 15.7 | 17.7 | 19.8 | 20.9 | 24.3 | 26.7 | 29.1 | 34.2 |

| 1600 | 7.17 | 8.03 | 8.87 | 9.79 | 10.7 | 11.6 | 12.5 | 13.5 | 14.5 | 15.5 | 16.6 | 18.7 | 20.9 | 22.1 | 25.7 | 28.1 | 30.7 | 36.1 |

| 1750 | 7.71 | 8.60 | 9.54 | 10.5 | 11.5 | 12.4 | 13.5 | 14.5 | 15.6 | 16.7 | 17.8 | 20.1 | 22.6 | 23.8 | 27.7 | 30.4 | 33.2 | 39.1 |

| 1800 | 7.87 | 8.82 | 9.77 | 10.7 | 11.7 | 12.7 | 13.8 | 14.8 | 16.0 | 17.1 | 18.2 | 20.6 | 23.1 | 24.4 | 28.3 | 31.1 | 34.0 | 40.0 |

| 2000 | 8.53 | 9.57 | 10.5 | 11.6 | 12.7 | 13.9 | 15.0 | 16.2 | 17.4 | 18.6 | 19.9 | 22.5 | 25.2 | 26.6 | 31.0 | 34.0 | 37.2 | 43.9 |

| 2400 | 9.88 | 11.0 | 12.2 | 13.4 | 14.7 | 16.0 | 17.4 | 18.8 | 20.2 | 21.6 | 23.1 | 26.2 | 29.3 | 31.0 | 36.1 | 39.8 | 43.5 | 51.4 |

| 2800 | 11.0 | 12.4 | 13.7 | 15.2 | 16.6 | 18.1 | 19.6 | 21.2 | 22.8 | 24.5 | 26.2 | 29.7 | 33.4 | 35.3 | 41.2 | 45.4 | 49.7 | 58.9 |

| 3000 | 11.6 | 13.1 | 14.5 | 16.0 | 17.5 | 19.2 | 20.8 | 22.5 | 24.2 | 25.9 | 27.8 | 31.5 | 35.4 | 37.4 | 43.8 | 48.2 | 52.8 | 62.6 |

| 3600 | 13.0 | 14.6 | 16.3 | 17.9 | 19.7 | 21.5 | 23.3 | 25.3 | 27.2 | 29.2 | 31.3 | 35.5 | 40.1 | 42.3 | 49.6 | 54.7 | 60.1 | 71.3 |

| 4000 | 13.8 | 15.5 | 17.3 | 19.1 | 21.0 | 22.9 | 24.9 | 27.0 | 29.0 | 31.2 | 33.4 | 38.1 | 42.9 | 45.4 | 53.3 | 58.8 | 64.5 | 76.7 |

| 5000 | 15.5 | 17.5 | 19.6 | 21.6 | 23.8 | 26.0 | 28.3 | 30.8 | 33.1 | 35.7 | 38.3 | 43.7 | 49.4 | 52.3 | 61.5 | 68.0 | ||

| 6000 | 17.0 | 19.3 | 21.3 | 23.7 | 26.2 | 28.7 | 31.3 | 34.0 | 36.7 | 39.5 | 42.5 | 48.5 | 54.9 | 58.2 | 68.7 | 76.0 | ||

・Avoid using in the gray highlighted range as the belt will have a shorter service life.

・The lower right of the bold outlined cells have a belt sprocket speed greater than 33m/s. Ensure the belt sprocket is well balanced.

Standard Transmission Torque N・m (Multiplied by the 1.79 coefficient of width)

| Small belt sprocket rotation speed r/min |

Upper row: Number of teeth of small belt sprocket Lower row: Pitch diameter mm | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 22 | 24 | 26 | 28 | 30 | 32 | 34 | 36 | 38 | 40 | 44 | 48 | 50 | 56 | 60 | 64 | 72 | |

| 50.93 | 56.02 | 61.12 | 66.21 | 71.30 | 76.39 | 81.49 | 86.58 | 91.67 | 96.77 | 101.86 | 112.05 | 122.23 | 127.32 | 142.60 | 152.79 | 162.97 | 183.35 | |

| 20 | 100 | 109 | 118 | 127 | 136 | 148 | 158 | 169 | 179 | 190 | 203 | 227 | 251 | 263 | 299 | 327 | 354 | 409 |

| 40 | 90.9 | 100 | 109 | 118 | 127 | 138 | 149 | 159 | 168 | 177 | 187 | 209 | 232 | 244 | 277 | 300 | 328 | 378 |

| 60 | 82.1 | 91.2 | 100 | 109 | 118 | 128 | 139 | 149 | 158 | 168 | 179 | 200 | 222 | 231 | 264 | 286 | 310 | 359 |

| 100 | 76.7 | 86.0 | 93.4 | 102 | 111 | 120 | 128 | 137 | 146 | 157 | 166 | 184 | 204 | 215 | 247 | 269 | 290 | 334 |

| 200 | 67.8 | 75.1 | 83.4 | 90.7 | 98.9 | 106 | 114 | 122 | 131 | 140 | 149 | 166 | 184 | 193 | 222 | 242 | 262 | 304 |

| 300 | 63.1 | 69.9 | 77.3 | 84.6 | 91.8 | 99.1 | 106 | 114 | 122 | 130 | 138 | 155 | 172 | 181 | 208 | 226 | 245 | 286 |

| 400 | 59.4 | 65.8 | 72.6 | 79.6 | 86.4 | 93.7 | 100 | 108 | 115 | 123 | 131 | 147 | 163 | 172 | 197 | 215 | 234 | 272 |

| 500 | 56.3 | 62.6 | 69.2 | 75.8 | 82.5 | 89.5 | 96.6 | 103 | 110 | 118 | 125 | 141 | 156 | 165 | 190 | 207 | 225 | 262 |

| 600 | 54.0 | 60.1 | 66.4 | 72.8 | 79.2 | 86.0 | 92.9 | 99.7 | 106 | 113 | 121 | 135 | 151 | 159 | 183 | 200 | 217 | 254 |

| 700 | 52.2 | 57.9 | 64.0 | 70.3 | 76.6 | 83.0 | 89.6 | 96.3 | 102 | 109 | 117 | 131 | 146 | 154 | 178 | 194 | 211 | 247 |

| 800 | 50.4 | 56.3 | 62.1 | 68.0 | 74.2 | 80.3 | 86.8 | 93.4 | 100 | 106 | 113 | 127 | 142 | 150 | 173 | 189 | 206 | 241 |

| 900 | 49.0 | 54.5 | 60.3 | 66.2 | 71.9 | 78.2 | 84.6 | 90.7 | 97.3 | 103 | 110 | 124 | 138 | 146 | 169 | 185 | 201 | 235 |

| 1000 | 47.7 | 52.9 | 58.8 | 64.2 | 70.3 | 76.0 | 82.3 | 88.6 | 94.6 | 101 | 107 | 121 | 135 | 142 | 165 | 180 | 197 | 230 |

| 1100 | 46.5 | 52.0 | 57.4 | 63.1 | 68.9 | 74.8 | 80.9 | 86.8 | 93.0 | 99.7 | 106 | 119 | 133 | 140 | 162 | 178 | 194 | 227 |

| 1200 | 45.8 | 51.1 | 56.5 | 62.1 | 67.8 | 73.5 | 79.4 | 85.5 | 91.4 | 97.9 | 104 | 117 | 131 | 138 | 160 | 175 | 191 | 225 |

| 1300 | 44.9 | 50.1 | 55.4 | 61.0 | 66.5 | 72.3 | 78.2 | 84.1 | 90.2 | 96.4 | 102 | 115 | 129 | 136 | 158 | 173 | 189 | 222 |

| 1400 | 44.3 | 49.4 | 54.7 | 60.1 | 65.5 | 71.2 | 77.1 | 82.8 | 89.1 | 95.2 | 101 | 114 | 127 | 134 | 156 | 171 | 187 | 220 |

| 1450 | 44.0 | 49.0 | 54.2 | 59.6 | 65.1 | 70.7 | 76.4 | 82.3 | 88.4 | 94.5 | 100 | 113 | 127 | 134 | 155 | 170 | 186 | 218 |

| 1500 | 43.6 | 48.6 | 53.8 | 59.2 | 64.6 | 70.3 | 75.8 | 81.9 | 87.7 | 93.9 | 100 | 113 | 126 | 133 | 154 | 169 | 185 | 218 |

| 1600 | 42.7 | 47.9 | 52.9 | 58.5 | 63.9 | 69.2 | 75.0 | 80.9 | 86.8 | 92.9 | 98.9 | 111 | 125 | 131 | 153 | 168 | 183 | 215 |

| 1750 | 42.0 | 47.0 | 52.0 | 57.2 | 62.8 | 68.0 | 73.7 | 79.4 | 85.3 | 91.2 | 97.3 | 110 | 123 | 130 | 151 | 165 | 181 | 213 |

| 1800 | 41.7 | 46.7 | 51.9 | 56.9 | 62.4 | 67.6 | 73.3 | 78.9 | 85.0 | 90.7 | 97.0 | 109 | 122 | 129 | 150 | 165 | 180 | 212 |

| 2000 | 40.8 | 45.6 | 50.4 | 55.8 | 60.8 | 66.4 | 71.7 | 77.5 | 83.2 | 89.1 | 95.0 | 107 | 120 | 127 | 148 | 162 | 177 | 209 |

| 2400 | 39.2 | 43.8 | 48.6 | 53.5 | 58.7 | 63.9 | 69.2 | 74.8 | 80.3 | 86.0 | 92.1 | 104 | 116 | 123 | 143 | 158 | 173 | 204 |

| 2800 | 37.7 | 42.2 | 47.0 | 51.9 | 56.7 | 61.7 | 67.1 | 72.4 | 78.0 | 83.5 | 89.5 | 101 | 114 | 120 | 140 | 155 | 169 | 200 |

| 3000 | 37.2 | 41.7 | 46.3 | 51.1 | 56.0 | 61.0 | 66.4 | 71.6 | 77.1 | 82.6 | 88.6 | 100 | 112 | 119 | 139 | 153 | 168 | 199 |

| 3600 | 34.5 | 38.6 | 43.3 | 47.6 | 52.2 | 57.1 | 62.1 | 67.1 | 72.1 | 77.6 | 83.0 | 94.3 | 106 | 112 | 131 | 145 | 159 | 189 |

| 4000 | 33.1 | 37.2 | 41.3 | 45.6 | 50.1 | 54.7 | 59.6 | 64.4 | 69.2 | 74.6 | 79.8 | 90.9 | 102 | 108 | 127 | 140 | 154 | 183 |

| 5000 | 29.7 | 33.4 | 37.4 | 41.3 | 45.4 | 49.7 | 54.0 | 58.8 | 63.3 | 68.1 | 73.0 | 83.4 | 94.3 | 100 | 117 | 129 | ||

| 6000 | 27.0 | 30.7 | 34.0 | 37.7 | 41.7 | 45.6 | 49.7 | 54.0 | 58.5 | 63.0 | 67.6 | 77.3 | 87.3 | 92.7 | 109 | 121 | ||

・Avoid using in the gray highlighted range as the belt will have a shorter service life.

・The lower right of the bold outlined cells have a belt sprocket speed greater than 33m/s. Ensure the belt sprocket is well balanced.

Available for the following belt sprocket types

| Type | Material | Base Model No. | Tooth no. range | |

|---|---|---|---|---|

| AF/A BF/B |

|

Carbon steel | P8M25AF P8M25A P8M25BF P8M25B |

20T~120T |

| Aluminum | P8M25AF-A P8M25A-A P8M25BF-A P8M25B-A |

20T~120T | ||

| Fit bore |  |

Carbon steel | P8M25AF-H□□□N-J□□D□M□□ P8M25BF-H□□□N-J□□D□M□□ |

20T~60T |

| Lock S type |

|

Carbon steel | P8M25AF-□S□□□ P8M25BF-□S□□□ |

20T~72T |

| Aluminum | P8M25AF-A-□S□□□ | 20T~60T | ||

| Plated | P8M25AF-□S□□□-K | 20T~72T | ||

Contact Information

Online Inquiries

For inquiries in English, visit the Inquiries page on our Tsubaki Group website.