仕様

( クリックで仕様毎の クリックで仕様毎の

詳細を表示します。) |

仕様記号 |

外観色 |

対応 |

最大

許容張力

kN/m |

チェーン

概略質量

kg/m2 |

許容速度

m/min |

使用温度範囲

゚C |

ピン材質 |

プラグ材質 |

プラグ外観色 |

能力線図 |

| 潤滑有 |

潤滑なし |

普通

(帯電防止有)  |

なし |

グレー |

△ |

15.4 |

7.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

能力線図を表示 |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2705-K09 |

228.6 |

200 |

3.52 |

1.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K12 |

304.8 |

200 |

4.69 |

2.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K15 |

381.0 |

200 |

5.86 |

2.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K18 |

457.2 |

200 |

7.04 |

3.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K21 |

533.4 |

100 |

8.21 |

4.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K24 |

609.6 |

100 |

9.38 |

4.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K27 |

685.8 |

100 |

10.5 |

5.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K30 |

762.0 |

100 |

11.7 |

5.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K33 |

838.2 |

100 |

12.9 |

6.37 |

DXF | お問合せください |

お問合せください |

| WT2705-K36 |

914.4 |

100 |

14.0 |

6.95 |

DXF | お問合せください |

お問合せください |

| WT2705-K39 |

990.6 |

80 |

15.2 |

7.53 |

DXF | お問合せください |

お問合せください |

| WT2705-K42 |

1066.8 |

80 |

16.4 |

8.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K45 |

1143.0 |

80 |

17.6 |

8.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K48 |

1219.2 |

80 |

18.7 |

9.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K51 |

1295.4 |

50 |

19.9 |

9.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K54 |

1371.6 |

50 |

21.1 |

10.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K57 |

1447.8 |

50 |

22.2 |

11.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K60 |

1524.0 |

50 |

23.4 |

11.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K63 |

1600.2 |

お問合せください |

24.6 |

12.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K66 |

1676.4 |

お問合せください |

25.8 |

12.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K69 |

1752.6 |

お問合せください |

26.9 |

13.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K72 |

1828.8 |

お問合せください |

28.1 |

13.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K75 |

1905 |

お問合せください |

29.3 |

14.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K78 |

1981.2 |

お問合せください |

30.5 |

15.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K81 |

2057.4 |

お問合せください |

31.6 |

15.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K84 |

2133.6 |

お問合せください |

32.8 |

16.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K87 |

2209.8 |

お問合せください |

34.0 |

16.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K90 |

2286 |

お問合せください |

35.2 |

17.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K93 |

2362.2 |

お問合せください |

36.3 |

17.96 |

DXF | お問合せください |

お問合せください |

| WT2705-K96 |

2438.4 |

お問合せください |

37.5 |

18.54 |

DXF | お問合せください |

お問合せください |

| WT2705-K99 |

2514.6 |

お問合せください |

38.7 |

19.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K102 |

2590.8 |

お問合せください |

39.8 |

19.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K105 |

2667 |

お問合せください |

41.0 |

20.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K108 |

2743.2 |

お問合せください |

42.2 |

20.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K111 |

2819.4 |

お問合せください |

43.4 |

21.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K114 |

2895.6 |

お問合せください |

44.5 |

22.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K117 |

2971.8 |

お問合せください |

45.7 |

22.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K120 |

3048 |

お問合せください |

46.9 |

23.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K123 |

3124.2 |

お問合せください |

48.1 |

23.75 |

DXF | お問合せください |

お問合せください |

| WT2705-K126 |

3200.4 |

お問合せください |

49.2 |

24.33 |

DXF | お問合せください |

お問合せください |

| WT2705-K129 |

3276.6 |

お問合せください |

50.4 |

24.91 |

DXF | お問合せください |

お問合せください |

| WT2705-K132 |

3352.8 |

お問合せください |

51.6 |

25.49 |

DXF | お問合せください |

お問合せください |

| WT2705-K135 |

3429 |

お問合せください |

52.8 |

26.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K138 |

3505.2 |

お問合せください |

53.9 |

26.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K141 |

3581.4 |

お問合せください |

55.1 |

27.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K144 |

3657.6 |

お問合せください |

56.3 |

27.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K147 |

3733.8 |

お問合せください |

57.5 |

28.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K150 |

3810 |

お問合せください |

58.6 |

28.96 |

DXF | お問合せください |

お問合せください |

|

普通

(帯電防止有)  |

B |

ブルー |

○ |

15.4 |

7.6 |

50 |

50 |

0~80 |

ポリプロピレン |

ポリアセタール |

イエロー |

能力線図を表示 |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2705-K09-B |

228.6 |

200 |

3.52 |

1.74 |

DXF | ¥778 |

お問合せください |

| WT2705-K12-B |

304.8 |

200 |

4.69 |

2.32 |

DXF | ¥990 |

お問合せください |

| WT2705-K15-B |

381.0 |

200 |

5.86 |

2.90 |

DXF | ¥1,180 |

お問合せください |

| WT2705-K18-B |

457.2 |

200 |

7.04 |

3.48 |

DXF | ¥1,390 |

お問合せください |

| WT2705-K21-B |

533.4 |

100 |

8.21 |

4.06 |

DXF | ¥1,570 |

お問合せください |

| WT2705-K24-B |

609.6 |

100 |

9.38 |

4.64 |

DXF | ¥1,810 |

お問合せください |

| WT2705-K27-B |

685.8 |

100 |

10.5 |

5.22 |

DXF | ¥2,020 |

お問合せください |

| WT2705-K30-B |

762.0 |

100 |

11.7 |

5.80 |

DXF | ¥2,240 |

お問合せください |

| WT2705-K33-B |

838.2 |

100 |

12.9 |

6.37 |

DXF | ¥2,480 |

お問合せください |

| WT2705-K36-B |

914.4 |

100 |

14.0 |

6.95 |

DXF | ¥2,680 |

お問合せください |

| WT2705-K39-B |

990.6 |

80 |

15.2 |

7.53 |

DXF | ¥2,900 |

お問合せください |

| WT2705-K42-B |

1066.8 |

80 |

16.4 |

8.11 |

DXF | ¥3,120 |

お問合せください |

| WT2705-K45-B |

1143.0 |

80 |

17.6 |

8.69 |

DXF | ¥3,380 |

お問合せください |

| WT2705-K48-B |

1219.2 |

80 |

18.7 |

9.27 |

DXF | ¥3,600 |

お問合せください |

| WT2705-K51-B |

1295.4 |

50 |

19.9 |

9.85 |

DXF | ¥3,800 |

お問合せください |

| WT2705-K54-B |

1371.6 |

50 |

21.1 |

10.43 |

DXF | ¥4,040 |

お問合せください |

| WT2705-K57-B |

1447.8 |

50 |

22.2 |

11.01 |

DXF | ¥4,260 |

お問合せください |

| WT2705-K60-B |

1524.0 |

50 |

23.4 |

11.59 |

DXF | ¥4,500 |

お問合せください |

| WT2705-K63-B |

1600.2 |

お問合せください |

24.6 |

12.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K66-B |

1676.4 |

お問合せください |

25.8 |

12.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K69-B |

1752.6 |

お問合せください |

26.9 |

13.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K72-B |

1828.8 |

お問合せください |

28.1 |

13.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K75-B |

1905 |

お問合せください |

29.3 |

14.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K78-B |

1981.2 |

お問合せください |

30.5 |

15.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K81-B |

2057.4 |

お問合せください |

31.6 |

15.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K84-B |

2133.6 |

お問合せください |

32.8 |

16.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K87-B |

2209.8 |

お問合せください |

34.0 |

16.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K90-B |

2286 |

お問合せください |

35.2 |

17.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K93-B |

2362.2 |

お問合せください |

36.3 |

17.96 |

DXF | お問合せください |

お問合せください |

| WT2705-K96-B |

2438.4 |

お問合せください |

37.5 |

18.54 |

DXF | お問合せください |

お問合せください |

| WT2705-K99-B |

2514.6 |

お問合せください |

38.7 |

19.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K102-B |

2590.8 |

お問合せください |

39.8 |

19.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K105-B |

2667 |

お問合せください |

41.0 |

20.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K108-B |

2743.2 |

お問合せください |

42.2 |

20.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K111-B |

2819.4 |

お問合せください |

43.4 |

21.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K114-B |

2895.6 |

お問合せください |

44.5 |

22.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K117-B |

2971.8 |

お問合せください |

45.7 |

22.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K120-B |

3048 |

お問合せください |

46.9 |

23.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K123-B |

3124.2 |

お問合せください |

48.1 |

23.75 |

DXF | お問合せください |

お問合せください |

| WT2705-K126-B |

3200.4 |

お問合せください |

49.2 |

24.33 |

DXF | お問合せください |

お問合せください |

| WT2705-K129-B |

3276.6 |

お問合せください |

50.4 |

24.91 |

DXF | お問合せください |

お問合せください |

| WT2705-K132-B |

3352.8 |

お問合せください |

51.6 |

25.49 |

DXF | お問合せください |

お問合せください |

| WT2705-K135-B |

3429 |

お問合せください |

52.8 |

26.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K138-B |

3505.2 |

お問合せください |

53.9 |

26.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K141-B |

3581.4 |

お問合せください |

55.1 |

27.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K144-B |

3657.6 |

お問合せください |

56.3 |

27.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K147-B |

3733.8 |

お問合せください |

57.5 |

28.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K150-B |

3810 |

お問合せください |

58.6 |

28.96 |

DXF | お問合せください |

お問合せください |

|

普通

(帯電防止有)  |

BL |

スカイブルー |

△ |

15.4 |

7.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

能力線図を表示 |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2705-K09-BL |

228.6 |

200 |

3.52 |

1.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K12-BL |

304.8 |

200 |

4.69 |

2.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K15-BL |

381.0 |

200 |

5.86 |

2.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K18-BL |

457.2 |

200 |

7.04 |

3.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K21-BL |

533.4 |

100 |

8.21 |

4.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K24-BL |

609.6 |

100 |

9.38 |

4.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K27-BL |

685.8 |

100 |

10.5 |

5.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K30-BL |

762.0 |

100 |

11.7 |

5.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K33-BL |

838.2 |

100 |

12.9 |

6.37 |

DXF | お問合せください |

お問合せください |

| WT2705-K36-BL |

914.4 |

100 |

14.0 |

6.95 |

DXF | お問合せください |

お問合せください |

| WT2705-K39-BL |

990.6 |

80 |

15.2 |

7.53 |

DXF | お問合せください |

お問合せください |

| WT2705-K42-BL |

1066.8 |

80 |

16.4 |

8.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K45-BL |

1143.0 |

80 |

17.6 |

8.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K48-BL |

1219.2 |

80 |

18.7 |

9.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K51-BL |

1295.4 |

50 |

19.9 |

9.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K54-BL |

1371.6 |

50 |

21.1 |

10.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K57-BL |

1447.8 |

50 |

22.2 |

11.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K60-BL |

1524.0 |

50 |

23.4 |

11.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K63-BL |

1600.2 |

お問合せください |

24.6 |

12.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K66-BL |

1676.4 |

お問合せください |

25.8 |

12.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K69-BL |

1752.6 |

お問合せください |

26.9 |

13.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K72-BL |

1828.8 |

お問合せください |

28.1 |

13.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K75-BL |

1905 |

お問合せください |

29.3 |

14.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K78-BL |

1981.2 |

お問合せください |

30.5 |

15.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K81-BL |

2057.4 |

お問合せください |

31.6 |

15.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K84-BL |

2133.6 |

お問合せください |

32.8 |

16.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K87-BL |

2209.8 |

お問合せください |

34.0 |

16.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K90-BL |

2286 |

お問合せください |

35.2 |

17.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K93-BL |

2362.2 |

お問合せください |

36.3 |

17.96 |

DXF | お問合せください |

お問合せください |

| WT2705-K96-BL |

2438.4 |

お問合せください |

37.5 |

18.54 |

DXF | お問合せください |

お問合せください |

| WT2705-K99-BL |

2514.6 |

お問合せください |

38.7 |

19.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K102-BL |

2590.8 |

お問合せください |

39.8 |

19.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K105-BL |

2667 |

お問合せください |

41.0 |

20.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K108-BL |

2743.2 |

お問合せください |

42.2 |

20.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K111-BL |

2819.4 |

お問合せください |

43.4 |

21.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K114-BL |

2895.6 |

お問合せください |

44.5 |

22.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K117-BL |

2971.8 |

お問合せください |

45.7 |

22.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K120-BL |

3048 |

お問合せください |

46.9 |

23.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K123-BL |

3124.2 |

お問合せください |

48.1 |

23.75 |

DXF | お問合せください |

お問合せください |

| WT2705-K126-BL |

3200.4 |

お問合せください |

49.2 |

24.33 |

DXF | お問合せください |

お問合せください |

| WT2705-K129-BL |

3276.6 |

お問合せください |

50.4 |

24.91 |

DXF | お問合せください |

お問合せください |

| WT2705-K132-BL |

3352.8 |

お問合せください |

51.6 |

25.49 |

DXF | お問合せください |

お問合せください |

| WT2705-K135-BL |

3429 |

お問合せください |

52.8 |

26.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K138-BL |

3505.2 |

お問合せください |

53.9 |

26.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K141-BL |

3581.4 |

お問合せください |

55.1 |

27.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K144-BL |

3657.6 |

お問合せください |

56.3 |

27.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K147-BL |

3733.8 |

お問合せください |

57.5 |

28.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K150-BL |

3810 |

お問合せください |

58.6 |

28.96 |

DXF | お問合せください |

お問合せください |

|

低摩擦・耐摩耗  |

LFW |

ホワイト |

△ |

15.4 |

7.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

- |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2705-K09-LFW |

228.6 |

200 |

3.52 |

1.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K12-LFW |

304.8 |

200 |

4.69 |

2.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K15-LFW |

381.0 |

200 |

5.86 |

2.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K18-LFW |

457.2 |

200 |

7.04 |

3.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K21-LFW |

533.4 |

100 |

8.21 |

4.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K24-LFW |

609.6 |

100 |

9.38 |

4.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K27-LFW |

685.8 |

100 |

10.5 |

5.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K30-LFW |

762.0 |

100 |

11.7 |

5.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K33-LFW |

838.2 |

100 |

12.9 |

6.37 |

DXF | お問合せください |

お問合せください |

| WT2705-K36-LFW |

914.4 |

100 |

14.0 |

6.95 |

DXF | お問合せください |

お問合せください |

| WT2705-K39-LFW |

990.6 |

80 |

15.2 |

7.53 |

DXF | お問合せください |

お問合せください |

| WT2705-K42-LFW |

1066.8 |

80 |

16.4 |

8.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K45-LFW |

1143.0 |

80 |

17.6 |

8.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K48-LFW |

1219.2 |

80 |

18.7 |

9.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K51-LFW |

1295.4 |

50 |

19.9 |

9.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K54-LFW |

1371.6 |

50 |

21.1 |

10.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K57-LFW |

1447.8 |

50 |

22.2 |

11.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K60-LFW |

1524.0 |

50 |

23.4 |

11.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K63-LFW |

1600.2 |

お問合せください |

24.6 |

12.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K66-LFW |

1676.4 |

お問合せください |

25.8 |

12.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K69-LFW |

1752.6 |

お問合せください |

26.9 |

13.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K72-LFW |

1828.8 |

お問合せください |

28.1 |

13.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K75-LFW |

1905 |

お問合せください |

29.3 |

14.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K78-LFW |

1981.2 |

お問合せください |

30.5 |

15.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K81-LFW |

2057.4 |

お問合せください |

31.6 |

15.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K84-LFW |

2133.6 |

お問合せください |

32.8 |

16.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K87-LFW |

2209.8 |

お問合せください |

34.0 |

16.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K90-LFW |

2286 |

お問合せください |

35.2 |

17.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K93-LFW |

2362.2 |

お問合せください |

36.3 |

17.96 |

DXF | お問合せください |

お問合せください |

| WT2705-K96-LFW |

2438.4 |

お問合せください |

37.5 |

18.54 |

DXF | お問合せください |

お問合せください |

| WT2705-K99-LFW |

2514.6 |

お問合せください |

38.7 |

19.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K102-LFW |

2590.8 |

お問合せください |

39.8 |

19.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K105-LFW |

2667 |

お問合せください |

41.0 |

20.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K108-LFW |

2743.2 |

お問合せください |

42.2 |

20.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K111-LFW |

2819.4 |

お問合せください |

43.4 |

21.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K114-LFW |

2895.6 |

お問合せください |

44.5 |

22.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K117-LFW |

2971.8 |

お問合せください |

45.7 |

22.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K120-LFW |

3048 |

お問合せください |

46.9 |

23.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K123-LFW |

3124.2 |

お問合せください |

48.1 |

23.75 |

DXF | お問合せください |

お問合せください |

| WT2705-K126-LFW |

3200.4 |

お問合せください |

49.2 |

24.33 |

DXF | お問合せください |

お問合せください |

| WT2705-K129-LFW |

3276.6 |

お問合せください |

50.4 |

24.91 |

DXF | お問合せください |

お問合せください |

| WT2705-K132-LFW |

3352.8 |

お問合せください |

51.6 |

25.49 |

DXF | お問合せください |

お問合せください |

| WT2705-K135-LFW |

3429 |

お問合せください |

52.8 |

26.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K138-LFW |

3505.2 |

お問合せください |

53.9 |

26.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K141-LFW |

3581.4 |

お問合せください |

55.1 |

27.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K144-LFW |

3657.6 |

お問合せください |

56.3 |

27.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K147-LFW |

3733.8 |

お問合せください |

57.5 |

28.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K150-LFW |

3810 |

お問合せください |

58.6 |

28.96 |

DXF | お問合せください |

お問合せください |

|

低摩擦・耐摩耗  |

LFG |

グリーン |

△ |

15.4 |

7.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

- |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2705-K09-LFG |

228.6 |

200 |

3.52 |

1.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K12-LFG |

304.8 |

200 |

4.69 |

2.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K15-LFG |

381.0 |

200 |

5.86 |

2.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K18-LFG |

457.2 |

200 |

7.04 |

3.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K21-LFG |

533.4 |

100 |

8.21 |

4.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K24-LFG |

609.6 |

100 |

9.38 |

4.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K27-LFG |

685.8 |

100 |

10.5 |

5.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K30-LFG |

762.0 |

100 |

11.7 |

5.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K33-LFG |

838.2 |

100 |

12.9 |

6.37 |

DXF | お問合せください |

お問合せください |

| WT2705-K36-LFG |

914.4 |

100 |

14.0 |

6.95 |

DXF | お問合せください |

お問合せください |

| WT2705-K39-LFG |

990.6 |

80 |

15.2 |

7.53 |

DXF | お問合せください |

お問合せください |

| WT2705-K42-LFG |

1066.8 |

80 |

16.4 |

8.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K45-LFG |

1143.0 |

80 |

17.6 |

8.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K48-LFG |

1219.2 |

80 |

18.7 |

9.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K51-LFG |

1295.4 |

50 |

19.9 |

9.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K54-LFG |

1371.6 |

50 |

21.1 |

10.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K57-LFG |

1447.8 |

50 |

22.2 |

11.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K60-LFG |

1524.0 |

50 |

23.4 |

11.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K63-LFG |

1600.2 |

お問合せください |

24.6 |

12.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K66-LFG |

1676.4 |

お問合せください |

25.8 |

12.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K69-LFG |

1752.6 |

お問合せください |

26.9 |

13.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K72-LFG |

1828.8 |

お問合せください |

28.1 |

13.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K75-LFG |

1905 |

お問合せください |

29.3 |

14.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K78-LFG |

1981.2 |

お問合せください |

30.5 |

15.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K81-LFG |

2057.4 |

お問合せください |

31.6 |

15.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K84-LFG |

2133.6 |

お問合せください |

32.8 |

16.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K87-LFG |

2209.8 |

お問合せください |

34.0 |

16.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K90-LFG |

2286 |

お問合せください |

35.2 |

17.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K93-LFG |

2362.2 |

お問合せください |

36.3 |

17.96 |

DXF | お問合せください |

お問合せください |

| WT2705-K96-LFG |

2438.4 |

お問合せください |

37.5 |

18.54 |

DXF | お問合せください |

お問合せください |

| WT2705-K99-LFG |

2514.6 |

お問合せください |

38.7 |

19.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K102-LFG |

2590.8 |

お問合せください |

39.8 |

19.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K105-LFG |

2667 |

お問合せください |

41.0 |

20.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K108-LFG |

2743.2 |

お問合せください |

42.2 |

20.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K111-LFG |

2819.4 |

お問合せください |

43.4 |

21.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K114-LFG |

2895.6 |

お問合せください |

44.5 |

22.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K117-LFG |

2971.8 |

お問合せください |

45.7 |

22.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K120-LFG |

3048 |

お問合せください |

46.9 |

23.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K123-LFG |

3124.2 |

お問合せください |

48.1 |

23.75 |

DXF | お問合せください |

お問合せください |

| WT2705-K126-LFG |

3200.4 |

お問合せください |

49.2 |

24.33 |

DXF | お問合せください |

お問合せください |

| WT2705-K129-LFG |

3276.6 |

お問合せください |

50.4 |

24.91 |

DXF | お問合せください |

お問合せください |

| WT2705-K132-LFG |

3352.8 |

お問合せください |

51.6 |

25.49 |

DXF | お問合せください |

お問合せください |

| WT2705-K135-LFG |

3429 |

お問合せください |

52.8 |

26.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K138-LFG |

3505.2 |

お問合せください |

53.9 |

26.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K141-LFG |

3581.4 |

お問合せください |

55.1 |

27.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K144-LFG |

3657.6 |

お問合せください |

56.3 |

27.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K147-LFG |

3733.8 |

お問合せください |

57.5 |

28.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K150-LFG |

3810 |

お問合せください |

58.6 |

28.96 |

DXF | お問合せください |

お問合せください |

|

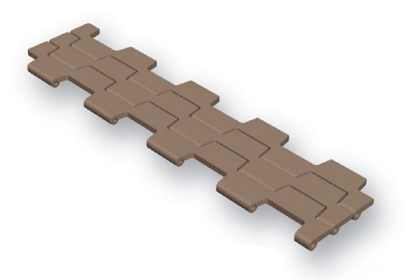

低摩擦・耐摩耗  |

LFB |

ブラウン |

○ |

15.4 |

7.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

能力線図を表示 |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2705-K09-LFB |

228.6 |

200 |

3.52 |

1.74 |

DXF | ¥866 |

お問合せください |

| WT2705-K12-LFB |

304.8 |

200 |

4.69 |

2.32 |

DXF | ¥1,090 |

お問合せください |

| WT2705-K15-LFB |

381.0 |

200 |

5.86 |

2.90 |

DXF | ¥1,300 |

お問合せください |

| WT2705-K18-LFB |

457.2 |

200 |

7.04 |

3.48 |

DXF | ¥1,540 |

お問合せください |

| WT2705-K21-LFB |

533.4 |

100 |

8.21 |

4.06 |

DXF | ¥1,730 |

お問合せください |

| WT2705-K24-LFB |

609.6 |

100 |

9.38 |

4.64 |

DXF | ¥1,990 |

お問合せください |

| WT2705-K27-LFB |

685.8 |

100 |

10.5 |

5.22 |

DXF | ¥2,220 |

お問合せください |

| WT2705-K30-LFB |

762.0 |

100 |

11.7 |

5.80 |

DXF | ¥2,480 |

お問合せください |

| WT2705-K33-LFB |

838.2 |

100 |

12.9 |

6.37 |

DXF | ¥2,700 |

お問合せください |

| WT2705-K36-LFB |

914.4 |

100 |

14.0 |

6.95 |

DXF | ¥2,960 |

お問合せください |

| WT2705-K39-LFB |

990.6 |

80 |

15.2 |

7.53 |

DXF | ¥3,200 |

お問合せください |

| WT2705-K42-LFB |

1066.8 |

80 |

16.4 |

8.11 |

DXF | ¥3,460 |

お問合せください |

| WT2705-K45-LFB |

1143.0 |

80 |

17.6 |

8.69 |

DXF | ¥3,720 |

お問合せください |

| WT2705-K48-LFB |

1219.2 |

80 |

18.7 |

9.27 |

DXF | ¥3,940 |

お問合せください |

| WT2705-K51-LFB |

1295.4 |

50 |

19.9 |

9.85 |

DXF | ¥4,180 |

お問合せください |

| WT2705-K54-LFB |

1371.6 |

50 |

21.1 |

10.43 |

DXF | ¥4,460 |

お問合せください |

| WT2705-K57-LFB |

1447.8 |

50 |

22.2 |

11.01 |

DXF | ¥4,700 |

お問合せください |

| WT2705-K60-LFB |

1524.0 |

50 |

23.4 |

11.59 |

DXF | ¥4,940 |

お問合せください |

| WT2705-K63-LFB |

1600.2 |

お問合せください |

24.6 |

12.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K66-LFB |

1676.4 |

お問合せください |

25.8 |

12.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K69-LFB |

1752.6 |

お問合せください |

26.9 |

13.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K72-LFB |

1828.8 |

お問合せください |

28.1 |

13.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K75-LFB |

1905 |

お問合せください |

29.3 |

14.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K78-LFB |

1981.2 |

お問合せください |

30.5 |

15.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K81-LFB |

2057.4 |

お問合せください |

31.6 |

15.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K84-LFB |

2133.6 |

お問合せください |

32.8 |

16.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K87-LFB |

2209.8 |

お問合せください |

34.0 |

16.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K90-LFB |

2286 |

お問合せください |

35.2 |

17.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K93-LFB |

2362.2 |

お問合せください |

36.3 |

17.96 |

DXF | お問合せください |

お問合せください |

| WT2705-K96-LFB |

2438.4 |

お問合せください |

37.5 |

18.54 |

DXF | お問合せください |

お問合せください |

| WT2705-K99-LFB |

2514.6 |

お問合せください |

38.7 |

19.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K102-LFB |

2590.8 |

お問合せください |

39.8 |

19.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K105-LFB |

2667 |

お問合せください |

41.0 |

20.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K108-LFB |

2743.2 |

お問合せください |

42.2 |

20.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K111-LFB |

2819.4 |

お問合せください |

43.4 |

21.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K114-LFB |

2895.6 |

お問合せください |

44.5 |

22.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K117-LFB |

2971.8 |

お問合せください |

45.7 |

22.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K120-LFB |

3048 |

お問合せください |

46.9 |

23.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K123-LFB |

3124.2 |

お問合せください |

48.1 |

23.75 |

DXF | お問合せください |

お問合せください |

| WT2705-K126-LFB |

3200.4 |

お問合せください |

49.2 |

24.33 |

DXF | お問合せください |

お問合せください |

| WT2705-K129-LFB |

3276.6 |

お問合せください |

50.4 |

24.91 |

DXF | お問合せください |

お問合せください |

| WT2705-K132-LFB |

3352.8 |

お問合せください |

51.6 |

25.49 |

DXF | お問合せください |

お問合せください |

| WT2705-K135-LFB |

3429 |

お問合せください |

52.8 |

26.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K138-LFB |

3505.2 |

お問合せください |

53.9 |

26.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K141-LFB |

3581.4 |

お問合せください |

55.1 |

27.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K144-LFB |

3657.6 |

お問合せください |

56.3 |

27.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K147-LFB |

3733.8 |

お問合せください |

57.5 |

28.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K150-LFB |

3810 |

お問合せください |

58.6 |

28.96 |

DXF | お問合せください |

お問合せください |

|

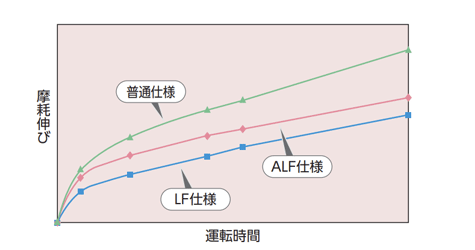

超低摩擦・耐摩耗  |

ALF |

ライトブルー |

△ |

15.4 |

7.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

- |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2705-K09-ALF |

228.6 |

200 |

3.52 |

1.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K12-ALF |

304.8 |

200 |

4.69 |

2.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K15-ALF |

381.0 |

200 |

5.86 |

2.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K18-ALF |

457.2 |

200 |

7.04 |

3.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K21-ALF |

533.4 |

100 |

8.21 |

4.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K24-ALF |

609.6 |

100 |

9.38 |

4.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K27-ALF |

685.8 |

100 |

10.5 |

5.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K30-ALF |

762.0 |

100 |

11.7 |

5.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K33-ALF |

838.2 |

100 |

12.9 |

6.37 |

DXF | お問合せください |

お問合せください |

| WT2705-K36-ALF |

914.4 |

100 |

14.0 |

6.95 |

DXF | お問合せください |

お問合せください |

| WT2705-K39-ALF |

990.6 |

80 |

15.2 |

7.53 |

DXF | お問合せください |

お問合せください |

| WT2705-K42-ALF |

1066.8 |

80 |

16.4 |

8.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K45-ALF |

1143.0 |

80 |

17.6 |

8.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K48-ALF |

1219.2 |

80 |

18.7 |

9.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K51-ALF |

1295.4 |

50 |

19.9 |

9.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K54-ALF |

1371.6 |

50 |

21.1 |

10.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K57-ALF |

1447.8 |

50 |

22.2 |

11.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K60-ALF |

1524.0 |

50 |

23.4 |

11.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K63-ALF |

1600.2 |

お問合せください |

24.6 |

12.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K66-ALF |

1676.4 |

お問合せください |

25.8 |

12.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K69-ALF |

1752.6 |

お問合せください |

26.9 |

13.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K72-ALF |

1828.8 |

お問合せください |

28.1 |

13.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K75-ALF |

1905 |

お問合せください |

29.3 |

14.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K78-ALF |

1981.2 |

お問合せください |

30.5 |

15.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K81-ALF |

2057.4 |

お問合せください |

31.6 |

15.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K84-ALF |

2133.6 |

お問合せください |

32.8 |

16.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K87-ALF |

2209.8 |

お問合せください |

34.0 |

16.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K90-ALF |

2286 |

お問合せください |

35.2 |

17.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K93-ALF |

2362.2 |

お問合せください |

36.3 |

17.96 |

DXF | お問合せください |

お問合せください |

| WT2705-K96-ALF |

2438.4 |

お問合せください |

37.5 |

18.54 |

DXF | お問合せください |

お問合せください |

| WT2705-K99-ALF |

2514.6 |

お問合せください |

38.7 |

19.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K102-ALF |

2590.8 |

お問合せください |

39.8 |

19.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K105-ALF |

2667 |

お問合せください |

41.0 |

20.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K108-ALF |

2743.2 |

お問合せください |

42.2 |

20.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K111-ALF |

2819.4 |

お問合せください |

43.4 |

21.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K114-ALF |

2895.6 |

お問合せください |

44.5 |

22.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K117-ALF |

2971.8 |

お問合せください |

45.7 |

22.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K120-ALF |

3048 |

お問合せください |

46.9 |

23.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K123-ALF |

3124.2 |

お問合せください |

48.1 |

23.75 |

DXF | お問合せください |

お問合せください |

| WT2705-K126-ALF |

3200.4 |

お問合せください |

49.2 |

24.33 |

DXF | お問合せください |

お問合せください |

| WT2705-K129-ALF |

3276.6 |

お問合せください |

50.4 |

24.91 |

DXF | お問合せください |

お問合せください |

| WT2705-K132-ALF |

3352.8 |

お問合せください |

51.6 |

25.49 |

DXF | お問合せください |

お問合せください |

| WT2705-K135-ALF |

3429 |

お問合せください |

52.8 |

26.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K138-ALF |

3505.2 |

お問合せください |

53.9 |

26.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K141-ALF |

3581.4 |

お問合せください |

55.1 |

27.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K144-ALF |

3657.6 |

お問合せください |

56.3 |

27.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K147-ALF |

3733.8 |

お問合せください |

57.5 |

28.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K150-ALF |

3810 |

お問合せください |

58.6 |

28.96 |

DXF | お問合せください |

お問合せください |

|

低摩擦  |

NLF |

ダークグレー |

△ |

15.4 |

7.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

- |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2705-K09-NLF |

228.6 |

200 |

3.52 |

1.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K12-NLF |

304.8 |

200 |

4.69 |

2.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K15-NLF |

381.0 |

200 |

5.86 |

2.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K18-NLF |

457.2 |

200 |

7.04 |

3.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K21-NLF |

533.4 |

100 |

8.21 |

4.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K24-NLF |

609.6 |

100 |

9.38 |

4.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K27-NLF |

685.8 |

100 |

10.5 |

5.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K30-NLF |

762.0 |

100 |

11.7 |

5.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K33-NLF |

838.2 |

100 |

12.9 |

6.37 |

DXF | お問合せください |

お問合せください |

| WT2705-K36-NLF |

914.4 |

100 |

14.0 |

6.95 |

DXF | お問合せください |

お問合せください |

| WT2705-K39-NLF |

990.6 |

80 |

15.2 |

7.53 |

DXF | お問合せください |

お問合せください |

| WT2705-K42-NLF |

1066.8 |

80 |

16.4 |

8.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K45-NLF |

1143.0 |

80 |

17.6 |

8.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K48-NLF |

1219.2 |

80 |

18.7 |

9.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K51-NLF |

1295.4 |

50 |

19.9 |

9.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K54-NLF |

1371.6 |

50 |

21.1 |

10.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K57-NLF |

1447.8 |

50 |

22.2 |

11.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K60-NLF |

1524.0 |

50 |

23.4 |

11.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K63-NLF |

1600.2 |

お問合せください |

24.6 |

12.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K66-NLF |

1676.4 |

お問合せください |

25.8 |

12.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K69-NLF |

1752.6 |

お問合せください |

26.9 |

13.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K72-NLF |

1828.8 |

お問合せください |

28.1 |

13.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K75-NLF |

1905 |

お問合せください |

29.3 |

14.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K78-NLF |

1981.2 |

お問合せください |

30.5 |

15.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K81-NLF |

2057.4 |

お問合せください |

31.6 |

15.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K84-NLF |

2133.6 |

お問合せください |

32.8 |

16.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K87-NLF |

2209.8 |

お問合せください |

34.0 |

16.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K90-NLF |

2286 |

お問合せください |

35.2 |

17.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K93-NLF |

2362.2 |

お問合せください |

36.3 |

17.96 |

DXF | お問合せください |

お問合せください |

| WT2705-K96-NLF |

2438.4 |

お問合せください |

37.5 |

18.54 |

DXF | お問合せください |

お問合せください |

| WT2705-K99-NLF |

2514.6 |

お問合せください |

38.7 |

19.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K102-NLF |

2590.8 |

お問合せください |

39.8 |

19.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K105-NLF |

2667 |

お問合せください |

41.0 |

20.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K108-NLF |

2743.2 |

お問合せください |

42.2 |

20.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K111-NLF |

2819.4 |

お問合せください |

43.4 |

21.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K114-NLF |

2895.6 |

お問合せください |

44.5 |

22.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K117-NLF |

2971.8 |

お問合せください |

45.7 |

22.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K120-NLF |

3048 |

お問合せください |

46.9 |

23.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K123-NLF |

3124.2 |

お問合せください |

48.1 |

23.75 |

DXF | お問合せください |

お問合せください |

| WT2705-K126-NLF |

3200.4 |

お問合せください |

49.2 |

24.33 |

DXF | お問合せください |

お問合せください |

| WT2705-K129-NLF |

3276.6 |

お問合せください |

50.4 |

24.91 |

DXF | お問合せください |

お問合せください |

| WT2705-K132-NLF |

3352.8 |

お問合せください |

51.6 |

25.49 |

DXF | お問合せください |

お問合せください |

| WT2705-K135-NLF |

3429 |

お問合せください |

52.8 |

26.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K138-NLF |

3505.2 |

お問合せください |

53.9 |

26.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K141-NLF |

3581.4 |

お問合せください |

55.1 |

27.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K144-NLF |

3657.6 |

お問合せください |

56.3 |

27.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K147-NLF |

3733.8 |

お問合せください |

57.5 |

28.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K150-NLF |

3810 |

お問合せください |

58.6 |

28.96 |

DXF | お問合せください |

お問合せください |

|

低摩擦  |

WR |

ダークグリーン |

△ |

15.4 |

7.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

- |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2705-K09-WR |

228.6 |

200 |

3.52 |

1.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K12-WR |

304.8 |

200 |

4.69 |

2.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K15-WR |

381.0 |

200 |

5.86 |

2.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K18-WR |

457.2 |

200 |

7.04 |

3.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K21-WR |

533.4 |

100 |

8.21 |

4.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K24-WR |

609.6 |

100 |

9.38 |

4.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K27-WR |

685.8 |

100 |

10.5 |

5.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K30-WR |

762.0 |

100 |

11.7 |

5.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K33-WR |

838.2 |

100 |

12.9 |

6.37 |

DXF | お問合せください |

お問合せください |

| WT2705-K36-WR |

914.4 |

100 |

14.0 |

6.95 |

DXF | お問合せください |

お問合せください |

| WT2705-K39-WR |

990.6 |

80 |

15.2 |

7.53 |

DXF | お問合せください |

お問合せください |

| WT2705-K42-WR |

1066.8 |

80 |

16.4 |

8.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K45-WR |

1143.0 |

80 |

17.6 |

8.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K48-WR |

1219.2 |

80 |

18.7 |

9.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K51-WR |

1295.4 |

50 |

19.9 |

9.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K54-WR |

1371.6 |

50 |

21.1 |

10.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K57-WR |

1447.8 |

50 |

22.2 |

11.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K60-WR |

1524.0 |

50 |

23.4 |

11.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K63-WR |

1600.2 |

お問合せください |

24.6 |

12.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K66-WR |

1676.4 |

お問合せください |

25.8 |

12.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K69-WR |

1752.6 |

お問合せください |

26.9 |

13.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K72-WR |

1828.8 |

お問合せください |

28.1 |

13.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K75-WR |

1905 |

お問合せください |

29.3 |

14.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K78-WR |

1981.2 |

お問合せください |

30.5 |

15.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K81-WR |

2057.4 |

お問合せください |

31.6 |

15.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K84-WR |

2133.6 |

お問合せください |

32.8 |

16.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K87-WR |

2209.8 |

お問合せください |

34.0 |

16.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K90-WR |

2286 |

お問合せください |

35.2 |

17.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K93-WR |

2362.2 |

お問合せください |

36.3 |

17.96 |

DXF | お問合せください |

お問合せください |

| WT2705-K96-WR |

2438.4 |

お問合せください |

37.5 |

18.54 |

DXF | お問合せください |

お問合せください |

| WT2705-K99-WR |

2514.6 |

お問合せください |

38.7 |

19.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K102-WR |

2590.8 |

お問合せください |

39.8 |

19.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K105-WR |

2667 |

お問合せください |

41.0 |

20.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K108-WR |

2743.2 |

お問合せください |

42.2 |

20.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K111-WR |

2819.4 |

お問合せください |

43.4 |

21.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K114-WR |

2895.6 |

お問合せください |

44.5 |

22.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K117-WR |

2971.8 |

お問合せください |

45.7 |

22.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K120-WR |

3048 |

お問合せください |

46.9 |

23.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K123-WR |

3124.2 |

お問合せください |

48.1 |

23.75 |

DXF | お問合せください |

お問合せください |

| WT2705-K126-WR |

3200.4 |

お問合せください |

49.2 |

24.33 |

DXF | お問合せください |

お問合せください |

| WT2705-K129-WR |

3276.6 |

お問合せください |

50.4 |

24.91 |

DXF | お問合せください |

お問合せください |

| WT2705-K132-WR |

3352.8 |

お問合せください |

51.6 |

25.49 |

DXF | お問合せください |

お問合せください |

| WT2705-K135-WR |

3429 |

お問合せください |

52.8 |

26.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K138-WR |

3505.2 |

お問合せください |

53.9 |

26.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K141-WR |

3581.4 |

お問合せください |

55.1 |

27.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K144-WR |

3657.6 |

お問合せください |

56.3 |

27.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K147-WR |

3733.8 |

お問合せください |

57.5 |

28.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K150-WR |

3810 |

お問合せください |

58.6 |

28.96 |

DXF | お問合せください |

お問合せください |

|

仕様

( クリックで仕様毎の クリックで仕様毎の

詳細を表示します。) |

仕様記号 |

外観色 |

対応 |

最大

許容張力

kN/m |

チェーン

概略質量

kg/m2 |

許容速度

m/min |

使用温度範囲

゚C |

ピン材質 |

プラグ材質 |

プラグ外観色 |

能力線図 |

| 潤滑有 |

潤滑なし |

低摩擦・耐摩耗  |

HG |

ネイビーブルー |

△ |

15.4 |

7.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

- |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2705-K09-HG |

228.6 |

200 |

3.52 |

1.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K12-HG |

304.8 |

200 |

4.69 |

2.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K15-HG |

381.0 |

200 |

5.86 |

2.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K18-HG |

457.2 |

200 |

7.04 |

3.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K21-HG |

533.4 |

100 |

8.21 |

4.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K24-HG |

609.6 |

100 |

9.38 |

4.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K27-HG |

685.8 |

100 |

10.5 |

5.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K30-HG |

762.0 |

100 |

11.7 |

5.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K33-HG |

838.2 |

100 |

12.9 |

6.37 |

DXF | お問合せください |

お問合せください |

| WT2705-K36-HG |

914.4 |

100 |

14.0 |

6.95 |

DXF | お問合せください |

お問合せください |

| WT2705-K39-HG |

990.6 |

80 |

15.2 |

7.53 |

DXF | お問合せください |

お問合せください |

| WT2705-K42-HG |

1066.8 |

80 |

16.4 |

8.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K45-HG |

1143.0 |

80 |

17.6 |

8.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K48-HG |

1219.2 |

80 |

18.7 |

9.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K51-HG |

1295.4 |

50 |

19.9 |

9.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K54-HG |

1371.6 |

50 |

21.1 |

10.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K57-HG |

1447.8 |

50 |

22.2 |

11.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K60-HG |

1524.0 |

50 |

23.4 |

11.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K63-HG |

1600.2 |

お問合せください |

24.6 |

12.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K66-HG |

1676.4 |

お問合せください |

25.8 |

12.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K69-HG |

1752.6 |

お問合せください |

26.9 |

13.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K72-HG |

1828.8 |

お問合せください |

28.1 |

13.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K75-HG |

1905 |

お問合せください |

29.3 |

14.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K78-HG |

1981.2 |

お問合せください |

30.5 |

15.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K81-HG |

2057.4 |

お問合せください |

31.6 |

15.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K84-HG |

2133.6 |

お問合せください |

32.8 |

16.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K87-HG |

2209.8 |

お問合せください |

34.0 |

16.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K90-HG |

2286 |

お問合せください |

35.2 |

17.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K93-HG |

2362.2 |

お問合せください |

36.3 |

17.96 |

DXF | お問合せください |

お問合せください |

| WT2705-K96-HG |

2438.4 |

お問合せください |

37.5 |

18.54 |

DXF | お問合せください |

お問合せください |

| WT2705-K99-HG |

2514.6 |

お問合せください |

38.7 |

19.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K102-HG |

2590.8 |

お問合せください |

39.8 |

19.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K105-HG |

2667 |

お問合せください |

41.0 |

20.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K108-HG |

2743.2 |

お問合せください |

42.2 |

20.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K111-HG |

2819.4 |

お問合せください |

43.4 |

21.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K114-HG |

2895.6 |

お問合せください |

44.5 |

22.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K117-HG |

2971.8 |

お問合せください |

45.7 |

22.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K120-HG |

3048 |

お問合せください |

46.9 |

23.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K123-HG |

3124.2 |

お問合せください |

48.1 |

23.75 |

DXF | お問合せください |

お問合せください |

| WT2705-K126-HG |

3200.4 |

お問合せください |

49.2 |

24.33 |

DXF | お問合せください |

お問合せください |

| WT2705-K129-HG |

3276.6 |

お問合せください |

50.4 |

24.91 |

DXF | お問合せください |

お問合せください |

| WT2705-K132-HG |

3352.8 |

お問合せください |

51.6 |

25.49 |

DXF | お問合せください |

お問合せください |

| WT2705-K135-HG |

3429 |

お問合せください |

52.8 |

26.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K138-HG |

3505.2 |

お問合せください |

53.9 |

26.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K141-HG |

3581.4 |

お問合せください |

55.1 |

27.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K144-HG |

3657.6 |

お問合せください |

56.3 |

27.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K147-HG |

3733.8 |

お問合せください |

57.5 |

28.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K150-HG |

3810 |

お問合せください |

58.6 |

28.96 |

DXF | お問合せください |

お問合せください |

|

高温  |

HTW |

ホワイト |

△ |

7.7 |

5.2 |

50 |

50 |

5~105 |

ポリプロピレン |

ポリプロピレン |

ブルー |

能力線図を表示 |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2705-K09-HTW |

228.6 |

200 |

1.76 |

1.19 |

DXF | お問合せください |

お問合せください |

| WT2705-K12-HTW |

304.8 |

200 |

2.34 |

1.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K15-HTW |

381.0 |

200 |

2.93 |

1.99 |

DXF | お問合せください |

お問合せください |

| WT2705-K18-HTW |

457.2 |

200 |

3.52 |

2.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K21-HTW |

533.4 |

100 |

4.10 |

2.78 |

DXF | お問合せください |

お問合せください |

| WT2705-K24-HTW |

609.6 |

100 |

4.69 |

3.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K27-HTW |

685.8 |

100 |

5.28 |

3.57 |

DXF | お問合せください |

お問合せください |

| WT2705-K30-HTW |

762.0 |

100 |

5.86 |

3.97 |

DXF | お問合せください |

お問合せください |

| WT2705-K33-HTW |

838.2 |

100 |

6.45 |

4.36 |

DXF | お問合せください |

お問合せください |

| WT2705-K36-HTW |

914.4 |

100 |

7.04 |

4.76 |

DXF | お問合せください |

お問合せください |

| WT2705-K39-HTW |

990.6 |

80 |

7.62 |

5.16 |

DXF | お問合せください |

お問合せください |

| WT2705-K42-HTW |

1066.8 |

80 |

8.21 |

5.55 |

DXF | お問合せください |

お問合せください |

| WT2705-K45-HTW |

1143.0 |

80 |

8.80 |

5.95 |

DXF | お問合せください |

お問合せください |

| WT2705-K48-HTW |

1219.2 |

80 |

9.38 |

6.34 |

DXF | お問合せください |

お問合せください |

| WT2705-K51-HTW |

1295.4 |

50 |

9.97 |

6.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K54-HTW |

1371.6 |

50 |

10.5 |

7.14 |

DXF | お問合せください |

お問合せください |

| WT2705-K57-HTW |

1447.8 |

50 |

11.1 |

7.53 |

DXF | お問合せください |

お問合せください |

| WT2705-K60-HTW |

1524.0 |

50 |

11.7 |

7.93 |

DXF | お問合せください |

お問合せください |

| WT2705-K63-HTW |

1600.2 |

お問合せください |

12.3 |

8.33 |

DXF | お問合せください |

お問合せください |

| WT2705-K66-HTW |

1676.4 |

お問合せください |

12.9 |

8.72 |

DXF | お問合せください |

お問合せください |

| WT2705-K69-HTW |

1752.6 |

お問合せください |

13.4 |

9.12 |

DXF | お問合せください |

お問合せください |

| WT2705-K72-HTW |

1828.8 |

お問合せください |

14.0 |

9.51 |

DXF | お問合せください |

お問合せください |

| WT2705-K75-HTW |

1905 |

お問合せください |

14.6 |

9.91 |

DXF | お問合せください |

お問合せください |

| WT2705-K78-HTW |

1981.2 |

お問合せください |

15.2 |

10.31 |

DXF | お問合せください |

お問合せください |

| WT2705-K81-HTW |

2057.4 |

お問合せください |

15.8 |

10.70 |

DXF | お問合せください |

お問合せください |

| WT2705-K84-HTW |

2133.6 |

お問合せください |

16.4 |

11.10 |

DXF | お問合せください |

お問合せください |

| WT2705-K87-HTW |

2209.8 |

お問合せください |

17.0 |

11.49 |

DXF | お問合せください |

お問合せください |

| WT2705-K90-HTW |

2286 |

お問合せください |

17.6 |

11.89 |

DXF | お問合せください |

お問合せください |

| WT2705-K93-HTW |

2362.2 |

お問合せください |

18.1 |

12.29 |

DXF | お問合せください |

お問合せください |

| WT2705-K96-HTW |

2438.4 |

お問合せください |

18.7 |

12.68 |

DXF | お問合せください |

お問合せください |

| WT2705-K99-HTW |

2514.6 |

お問合せください |

19.3 |

13.08 |

DXF | お問合せください |

お問合せください |

| WT2705-K102-HTW |

2590.8 |

お問合せください |

19.9 |

13.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K105-HTW |

2667 |

お問合せください |

20.5 |

13.87 |

DXF | お問合せください |

お問合せください |

| WT2705-K108-HTW |

2743.2 |

お問合せください |

21.1 |

14.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K111-HTW |

2819.4 |

お問合せください |

21.7 |

14.66 |

DXF | お問合せください |

お問合せください |

| WT2705-K114-HTW |

2895.6 |

お問合せください |

22.2 |

15.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K117-HTW |

2971.8 |

お問合せください |

22.8 |

15.46 |

DXF | お問合せください |

お問合せください |

| WT2705-K120-HTW |

3048 |

お問合せください |

23.4 |

15.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K123-HTW |

3124.2 |

お問合せください |

24.0 |

16.25 |

DXF | お問合せください |

お問合せください |

| WT2705-K126-HTW |

3200.4 |

お問合せください |

24.6 |

16.65 |

DXF | お問合せください |

お問合せください |

| WT2705-K129-HTW |

3276.6 |

お問合せください |

25.2 |

17.04 |

DXF | お問合せください |

お問合せください |

| WT2705-K132-HTW |

3352.8 |

お問合せください |

25.8 |

17.44 |

DXF | お問合せください |

お問合せください |

| WT2705-K135-HTW |

3429 |

お問合せください |

26.4 |

17.83 |

DXF | お問合せください |

お問合せください |

| WT2705-K138-HTW |

3505.2 |

お問合せください |

26.9 |

18.23 |

DXF | お問合せください |

お問合せください |

| WT2705-K141-HTW |

3581.4 |

お問合せください |

27.5 |

18.63 |

DXF | お問合せください |

お問合せください |

| WT2705-K144-HTW |

3657.6 |

お問合せください |

28.1 |

19.02 |

DXF | お問合せください |

お問合せください |

| WT2705-K147-HTW |

3733.8 |

お問合せください |

28.7 |

19.42 |

DXF | お問合せください |

お問合せください |

| WT2705-K150-HTW |

3810 |

お問合せください |

29.3 |

19.82 |

DXF | お問合せください |

お問合せください |

|

導電  |

E |

ブラック |

△ |

10.8 |

7.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

- |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2705-K09-E |

228.6 |

200 |

2.46 |

1.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K12-E |

304.8 |

200 |

3.29 |

2.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K15-E |

381.0 |

200 |

4.11 |

2.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K18-E |

457.2 |

200 |

4.93 |

3.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K21-E |

533.4 |

100 |

5.76 |

4.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K24-E |

609.6 |

100 |

6.58 |

4.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K27-E |

685.8 |

100 |

7.40 |

5.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K30-E |

762.0 |

100 |

8.22 |

5.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K33-E |

838.2 |

100 |

9.05 |

6.37 |

DXF | お問合せください |

お問合せください |

| WT2705-K36-E |

914.4 |

100 |

9.87 |

6.95 |

DXF | お問合せください |

お問合せください |

| WT2705-K39-E |

990.6 |

80 |

10.6 |

7.53 |

DXF | お問合せください |

お問合せください |

| WT2705-K42-E |

1066.8 |

80 |

11.5 |

8.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K45-E |

1143.0 |

80 |

12.3 |

8.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K48-E |

1219.2 |

80 |

13.1 |

9.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K51-E |

1295.4 |

50 |

13.9 |

9.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K54-E |

1371.6 |

50 |

14.8 |

10.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K57-E |

1447.8 |

50 |

15.6 |

11.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K60-E |

1524.0 |

50 |

16.4 |

11.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K63-E |

1600.2 |

お問合せください |

17.2 |

12.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K66-E |

1676.4 |

お問合せください |

18.1 |

12.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K69-E |

1752.6 |

お問合せください |

18.9 |

13.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K72-E |

1828.8 |

お問合せください |

19.7 |

13.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K75-E |

1905 |

お問合せください |

20.5 |

14.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K78-E |

1981.2 |

お問合せください |

21.3 |

15.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K81-E |

2057.4 |

お問合せください |

22.2 |

15.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K84-E |

2133.6 |

お問合せください |

23.0 |

16.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K87-E |

2209.8 |

お問合せください |

23.8 |

16.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K90-E |

2286 |

お問合せください |

24.6 |

17.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K93-E |

2362.2 |

お問合せください |

25.5 |

17.96 |

DXF | お問合せください |

お問合せください |

| WT2705-K96-E |

2438.4 |

お問合せください |

26.3 |

18.54 |

DXF | お問合せください |

お問合せください |

| WT2705-K99-E |

2514.6 |

お問合せください |

27.1 |

19.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K102-E |

2590.8 |

お問合せください |

27.9 |

19.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K105-E |

2667 |

お問合せください |

28.8 |

20.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K108-E |

2743.2 |

お問合せください |

29.6 |

20.85 |

DXF | お問合せください |

お問合せください |

| WT2705-K111-E |

2819.4 |

お問合せください |

30.4 |

21.43 |

DXF | お問合せください |

お問合せください |

| WT2705-K114-E |

2895.6 |

お問合せください |

31.2 |

22.01 |

DXF | お問合せください |

お問合せください |

| WT2705-K117-E |

2971.8 |

お問合せください |

32.0 |

22.59 |

DXF | お問合せください |

お問合せください |

| WT2705-K120-E |

3048 |

お問合せください |

32.9 |

23.17 |

DXF | お問合せください |

お問合せください |

| WT2705-K123-E |

3124.2 |

お問合せください |

33.7 |

23.75 |

DXF | お問合せください |

お問合せください |

| WT2705-K126-E |

3200.4 |

お問合せください |

34.5 |

24.33 |

DXF | お問合せください |

お問合せください |

| WT2705-K129-E |

3276.6 |

お問合せください |

35.3 |

24.91 |

DXF | お問合せください |

お問合せください |

| WT2705-K132-E |

3352.8 |

お問合せください |

36.2 |

25.49 |

DXF | お問合せください |

お問合せください |

| WT2705-K135-E |

3429 |

お問合せください |

37.0 |

26.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K138-E |

3505.2 |

お問合せください |

37.8 |

26.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K141-E |

3581.4 |

お問合せください |

38.6 |

27.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K144-E |

3657.6 |

お問合せください |

39.5 |

27.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K147-E |

3733.8 |

お問合せください |

40.3 |

28.38 |

DXF | お問合せください |

お問合せください |

| WT2705-K150-E |

3810 |

お問合せください |

41.1 |

28.96 |

DXF | お問合せください |

お問合せください |

|

抗菌・防カビ  |

MWS |

クリーム |

△ |

15.4 |

7.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

- |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2705-K09-MWS |

228.6 |

200 |

3.52 |

1.74 |

DXF | お問合せください |

お問合せください |

| WT2705-K12-MWS |

304.8 |

200 |

4.69 |

2.32 |

DXF | お問合せください |

お問合せください |

| WT2705-K15-MWS |

381.0 |

200 |

5.86 |

2.90 |

DXF | お問合せください |

お問合せください |

| WT2705-K18-MWS |

457.2 |

200 |

7.04 |

3.48 |

DXF | お問合せください |

お問合せください |

| WT2705-K21-MWS |

533.4 |

100 |

8.21 |

4.06 |

DXF | お問合せください |

お問合せください |

| WT2705-K24-MWS |

609.6 |

100 |

9.38 |

4.64 |

DXF | お問合せください |

お問合せください |

| WT2705-K27-MWS |

685.8 |

100 |

10.5 |

5.22 |

DXF | お問合せください |

お問合せください |

| WT2705-K30-MWS |

762.0 |

100 |

11.7 |

5.80 |

DXF | お問合せください |

お問合せください |

| WT2705-K33-MWS |

838.2 |

100 |

12.9 |

6.37 |

DXF | お問合せください |

お問合せください |

| WT2705-K36-MWS |

914.4 |

100 |

14.0 |

6.95 |

DXF | お問合せください |

お問合せください |

| WT2705-K39-MWS |

990.6 |

80 |

15.2 |

7.53 |

DXF | お問合せください |

お問合せください |

| WT2705-K42-MWS |

1066.8 |

80 |

16.4 |

8.11 |

DXF | お問合せください |

お問合せください |

| WT2705-K45-MWS |

1143.0 |

80 |

17.6 |

8.69 |

DXF | お問合せください |

お問合せください |

| WT2705-K48-MWS |

1219.2 |

80 |

18.7 |

9.27 |

DXF | お問合せください |

お問合せください |

| WT2705-K51-MWS |

1295.4 |