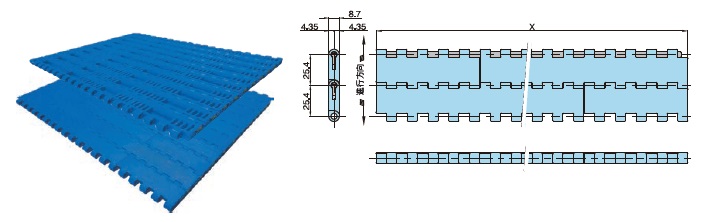

プラスチックモジュラーチェーンWT2515-W形 主要諸元

WT2515-W

特長

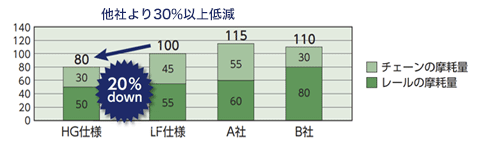

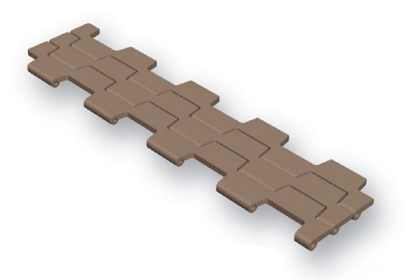

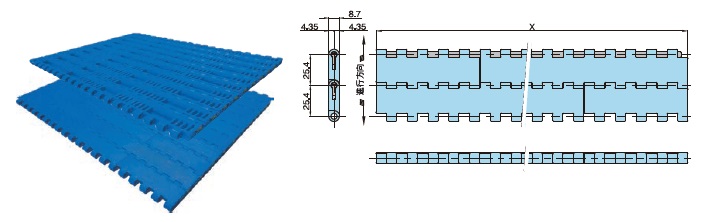

- ・幅85mmと170mmのモジュールリンクの組合せでチェーンを構成しています。

- ・ピン抜け止めはプラグ方式を採用。チェーンの連結・分解等メンテナンスが容易です。

[クリックで拡大]

カタログ・取扱説明書

主要諸元・価格・納期

| チェーンピッチ mm |

開孔率 % |

バックベンド半径 mm |

| 25.4 |

2

|

25 |

標準シリーズ

仕様

( クリックで仕様毎の クリックで仕様毎の

詳細を表示します。) |

仕様記号 |

外観色 |

対応 |

最大

許容張力

kN/m |

チェーン

概略質量

kg/m2 |

許容速度

m/min |

使用温度範囲

゚C |

ピン材質 |

プラグ材質 |

プラグ外観色 |

能力線図 |

| 潤滑有 |

潤滑なし |

普通

(帯電防止有)  |

なし |

グレー |

△ |

12.8 |

8.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

能力線図を表示 |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2515-W85 |

85 |

200 |

1.08 |

0.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W170 |

170 |

200 |

2.17 |

1.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W255 |

255 |

200 |

3.26 |

2.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W340 |

340 |

200 |

4.35 |

2.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W425 |

425 |

200 |

5.44 |

3.66 |

DXF | お問合せください |

お問合せください |

| WT2515-W510 |

510 |

100 |

6.52 |

4.39 |

DXF | お問合せください |

お問合せください |

| WT2515-W595 |

595 |

100 |

7.61 |

5.12 |

DXF | お問合せください |

お問合せください |

| WT2515-W680 |

680 |

100 |

8.70 |

5.85 |

DXF | お問合せください |

お問合せください |

| WT2515-W765 |

765 |

100 |

9.79 |

6.58 |

DXF | お問合せください |

お問合せください |

| WT2515-W850 |

850 |

100 |

10.8 |

7.31 |

DXF | お問合せください |

お問合せください |

| WT2515-W935 |

935 |

100 |

11.9 |

8.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W1020 |

1020 |

80 |

13.0 |

8.78 |

DXF | お問合せください |

お問合せください |

| WT2515-W1105 |

1105 |

80 |

14.1 |

9.51 |

DXF | お問合せください |

お問合せください |

| WT2515-W1190 |

1190 |

80 |

15.2 |

10.24 |

DXF | お問合せください |

お問合せください |

| WT2515-W1275 |

1275 |

50 |

16.3 |

10.97 |

DXF | お問合せください |

お問合せください |

| WT2515-W1360 |

1360 |

50 |

17.4 |

11.70 |

DXF | お問合せください |

お問合せください |

| WT2515-W1445 |

1445 |

50 |

18.4 |

12.43 |

DXF | お問合せください |

お問合せください |

| WT2515-W1530 |

1530 |

50 |

19.5 |

13.16 |

DXF | お問合せください |

お問合せください |

| WT2515-W1615 |

1615 |

50 |

20.6 |

13.89 |

DXF | お問合せください |

お問合せください |

| WT2515-W1700 |

1700 |

50 |

21.7 |

14.62 |

DXF | お問合せください |

お問合せください |

| WT2515-W1785 |

1785 |

50 |

22.8 |

15.36 |

DXF | お問合せください |

お問合せください |

| WT2515-W1870 |

1870 |

40 |

23.9 |

16.09 |

DXF | お問合せください |

お問合せください |

| WT2515-W1955 |

1955 |

お問合せください |

25.0 |

16.82 |

DXF | お問合せください |

お問合せください |

| WT2515-W2040 |

2040 |

お問合せください |

26.1 |

17.55 |

DXF | お問合せください |

お問合せください |

| WT2515-W2125 |

2125 |

お問合せください |

27.2 |

18.28 |

DXF | お問合せください |

お問合せください |

| WT2515-W2210 |

2210 |

お問合せください |

28.2 |

19.01 |

DXF | お問合せください |

お問合せください |

| WT2515-W2295 |

2295 |

お問合せください |

29.3 |

19.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W2380 |

2380 |

お問合せください |

30.4 |

20.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W2465 |

2465 |

お問合せください |

31.5 |

21.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W2550 |

2550 |

お問合せください |

32.6 |

21.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W2635 |

2635 |

お問合せください |

33.7 |

22.67 |

DXF | お問合せください |

お問合せください |

| WT2515-W2720 |

2720 |

お問合せください |

34.8 |

23.40 |

DXF | お問合せください |

お問合せください |

| WT2515-W2805 |

2805 |

お問合せください |

35.9 |

24.13 |

DXF | お問合せください |

お問合せください |

| WT2515-W2890 |

2890 |

お問合せください |

36.9 |

24.86 |

DXF | お問合せください |

お問合せください |

| WT2515-W2975 |

2975 |

お問合せください |

38.0 |

25.59 |

DXF | お問合せください |

お問合せください |

| WT2515-W3060 |

3060 |

お問合せください |

39.1 |

26.32 |

DXF | お問合せください |

お問合せください |

| WT2515-W3145 |

3145 |

お問合せください |

40.2 |

27.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W3230 |

3230 |

お問合せください |

41.3 |

27.78 |

DXF | お問合せください |

お問合せください |

|

普通

(帯電防止有)  |

B |

ブルー |

△ |

12.8 |

8.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

能力線図を表示 |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2515-W85-B |

85 |

200 |

1.08 |

0.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W170-B |

170 |

200 |

2.17 |

1.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W255-B |

255 |

200 |

3.26 |

2.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W340-B |

340 |

200 |

4.35 |

2.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W425-B |

425 |

200 |

5.44 |

3.66 |

DXF | お問合せください |

お問合せください |

| WT2515-W510-B |

510 |

100 |

6.52 |

4.39 |

DXF | お問合せください |

お問合せください |

| WT2515-W595-B |

595 |

100 |

7.61 |

5.12 |

DXF | お問合せください |

お問合せください |

| WT2515-W680-B |

680 |

100 |

8.70 |

5.85 |

DXF | お問合せください |

お問合せください |

| WT2515-W765-B |

765 |

100 |

9.79 |

6.58 |

DXF | お問合せください |

お問合せください |

| WT2515-W850-B |

850 |

100 |

10.8 |

7.31 |

DXF | お問合せください |

お問合せください |

| WT2515-W935-B |

935 |

100 |

11.9 |

8.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W1020-B |

1020 |

80 |

13.0 |

8.78 |

DXF | お問合せください |

お問合せください |

| WT2515-W1105-B |

1105 |

80 |

14.1 |

9.51 |

DXF | お問合せください |

お問合せください |

| WT2515-W1190-B |

1190 |

80 |

15.2 |

10.24 |

DXF | お問合せください |

お問合せください |

| WT2515-W1275-B |

1275 |

50 |

16.3 |

10.97 |

DXF | お問合せください |

お問合せください |

| WT2515-W1360-B |

1360 |

50 |

17.4 |

11.70 |

DXF | お問合せください |

お問合せください |

| WT2515-W1445-B |

1445 |

50 |

18.4 |

12.43 |

DXF | お問合せください |

お問合せください |

| WT2515-W1530-B |

1530 |

50 |

19.5 |

13.16 |

DXF | お問合せください |

お問合せください |

| WT2515-W1615-B |

1615 |

50 |

20.6 |

13.89 |

DXF | お問合せください |

お問合せください |

| WT2515-W1700-B |

1700 |

50 |

21.7 |

14.62 |

DXF | お問合せください |

お問合せください |

| WT2515-W1785-B |

1785 |

50 |

22.8 |

15.36 |

DXF | お問合せください |

お問合せください |

| WT2515-W1870-B |

1870 |

40 |

23.9 |

16.09 |

DXF | お問合せください |

お問合せください |

| WT2515-W1955-B |

1955 |

お問合せください |

25.0 |

16.82 |

DXF | お問合せください |

お問合せください |

| WT2515-W2040-B |

2040 |

お問合せください |

26.1 |

17.55 |

DXF | お問合せください |

お問合せください |

| WT2515-W2125-B |

2125 |

お問合せください |

27.2 |

18.28 |

DXF | お問合せください |

お問合せください |

| WT2515-W2210-B |

2210 |

お問合せください |

28.2 |

19.01 |

DXF | お問合せください |

お問合せください |

| WT2515-W2295-B |

2295 |

お問合せください |

29.3 |

19.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W2380-B |

2380 |

お問合せください |

30.4 |

20.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W2465-B |

2465 |

お問合せください |

31.5 |

21.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W2550-B |

2550 |

お問合せください |

32.6 |

21.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W2635-B |

2635 |

お問合せください |

33.7 |

22.67 |

DXF | お問合せください |

お問合せください |

| WT2515-W2720-B |

2720 |

お問合せください |

34.8 |

23.40 |

DXF | お問合せください |

お問合せください |

| WT2515-W2805-B |

2805 |

お問合せください |

35.9 |

24.13 |

DXF | お問合せください |

お問合せください |

| WT2515-W2890-B |

2890 |

お問合せください |

36.9 |

24.86 |

DXF | お問合せください |

お問合せください |

| WT2515-W2975-B |

2975 |

お問合せください |

38.0 |

25.59 |

DXF | お問合せください |

お問合せください |

| WT2515-W3060-B |

3060 |

お問合せください |

39.1 |

26.32 |

DXF | お問合せください |

お問合せください |

| WT2515-W3145-B |

3145 |

お問合せください |

40.2 |

27.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W3230-B |

3230 |

お問合せください |

41.3 |

27.78 |

DXF | お問合せください |

お問合せください |

|

普通

(帯電防止有)  |

BL |

スカイブルー |

△ |

12.8 |

8.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

能力線図を表示 |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2515-W85-BL |

85 |

200 |

1.08 |

0.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W170-BL |

170 |

200 |

2.17 |

1.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W255-BL |

255 |

200 |

3.26 |

2.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W340-BL |

340 |

200 |

4.35 |

2.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W425-BL |

425 |

200 |

5.44 |

3.66 |

DXF | お問合せください |

お問合せください |

| WT2515-W510-BL |

510 |

100 |

6.52 |

4.39 |

DXF | お問合せください |

お問合せください |

| WT2515-W595-BL |

595 |

100 |

7.61 |

5.12 |

DXF | お問合せください |

お問合せください |

| WT2515-W680-BL |

680 |

100 |

8.70 |

5.85 |

DXF | お問合せください |

お問合せください |

| WT2515-W765-BL |

765 |

100 |

9.79 |

6.58 |

DXF | お問合せください |

お問合せください |

| WT2515-W850-BL |

850 |

100 |

10.8 |

7.31 |

DXF | お問合せください |

お問合せください |

| WT2515-W935-BL |

935 |

100 |

11.9 |

8.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W1020-BL |

1020 |

80 |

13.0 |

8.78 |

DXF | お問合せください |

お問合せください |

| WT2515-W1105-BL |

1105 |

80 |

14.1 |

9.51 |

DXF | お問合せください |

お問合せください |

| WT2515-W1190-BL |

1190 |

80 |

15.2 |

10.24 |

DXF | お問合せください |

お問合せください |

| WT2515-W1275-BL |

1275 |

50 |

16.3 |

10.97 |

DXF | お問合せください |

お問合せください |

| WT2515-W1360-BL |

1360 |

50 |

17.4 |

11.70 |

DXF | お問合せください |

お問合せください |

| WT2515-W1445-BL |

1445 |

50 |

18.4 |

12.43 |

DXF | お問合せください |

お問合せください |

| WT2515-W1530-BL |

1530 |

50 |

19.5 |

13.16 |

DXF | お問合せください |

お問合せください |

| WT2515-W1615-BL |

1615 |

50 |

20.6 |

13.89 |

DXF | お問合せください |

お問合せください |

| WT2515-W1700-BL |

1700 |

50 |

21.7 |

14.62 |

DXF | お問合せください |

お問合せください |

| WT2515-W1785-BL |

1785 |

50 |

22.8 |

15.36 |

DXF | お問合せください |

お問合せください |

| WT2515-W1870-BL |

1870 |

40 |

23.9 |

16.09 |

DXF | お問合せください |

お問合せください |

| WT2515-W1955-BL |

1955 |

お問合せください |

25.0 |

16.82 |

DXF | お問合せください |

お問合せください |

| WT2515-W2040-BL |

2040 |

お問合せください |

26.1 |

17.55 |

DXF | お問合せください |

お問合せください |

| WT2515-W2125-BL |

2125 |

お問合せください |

27.2 |

18.28 |

DXF | お問合せください |

お問合せください |

| WT2515-W2210-BL |

2210 |

お問合せください |

28.2 |

19.01 |

DXF | お問合せください |

お問合せください |

| WT2515-W2295-BL |

2295 |

お問合せください |

29.3 |

19.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W2380-BL |

2380 |

お問合せください |

30.4 |

20.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W2465-BL |

2465 |

お問合せください |

31.5 |

21.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W2550-BL |

2550 |

お問合せください |

32.6 |

21.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W2635-BL |

2635 |

お問合せください |

33.7 |

22.67 |

DXF | お問合せください |

お問合せください |

| WT2515-W2720-BL |

2720 |

お問合せください |

34.8 |

23.40 |

DXF | お問合せください |

お問合せください |

| WT2515-W2805-BL |

2805 |

お問合せください |

35.9 |

24.13 |

DXF | お問合せください |

お問合せください |

| WT2515-W2890-BL |

2890 |

お問合せください |

36.9 |

24.86 |

DXF | お問合せください |

お問合せください |

| WT2515-W2975-BL |

2975 |

お問合せください |

38.0 |

25.59 |

DXF | お問合せください |

お問合せください |

| WT2515-W3060-BL |

3060 |

お問合せください |

39.1 |

26.32 |

DXF | お問合せください |

お問合せください |

| WT2515-W3145-BL |

3145 |

お問合せください |

40.2 |

27.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W3230-BL |

3230 |

お問合せください |

41.3 |

27.78 |

DXF | お問合せください |

お問合せください |

|

低摩擦・耐摩耗  |

LFW |

ホワイト |

△ |

12.8 |

8.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

能力線図を表示 |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2515-W85-LFW |

85 |

200 |

1.08 |

0.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W170-LFW |

170 |

200 |

2.17 |

1.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W255-LFW |

255 |

200 |

3.26 |

2.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W340-LFW |

340 |

200 |

4.35 |

2.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W425-LFW |

425 |

200 |

5.44 |

3.66 |

DXF | お問合せください |

お問合せください |

| WT2515-W510-LFW |

510 |

100 |

6.52 |

4.39 |

DXF | お問合せください |

お問合せください |

| WT2515-W595-LFW |

595 |

100 |

7.61 |

5.12 |

DXF | お問合せください |

お問合せください |

| WT2515-W680-LFW |

680 |

100 |

8.70 |

5.85 |

DXF | お問合せください |

お問合せください |

| WT2515-W765-LFW |

765 |

100 |

9.79 |

6.58 |

DXF | お問合せください |

お問合せください |

| WT2515-W850-LFW |

850 |

100 |

10.8 |

7.31 |

DXF | お問合せください |

お問合せください |

| WT2515-W935-LFW |

935 |

100 |

11.9 |

8.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W1020-LFW |

1020 |

80 |

13.0 |

8.78 |

DXF | お問合せください |

お問合せください |

| WT2515-W1105-LFW |

1105 |

80 |

14.1 |

9.51 |

DXF | お問合せください |

お問合せください |

| WT2515-W1190-LFW |

1190 |

80 |

15.2 |

10.24 |

DXF | お問合せください |

お問合せください |

| WT2515-W1275-LFW |

1275 |

50 |

16.3 |

10.97 |

DXF | お問合せください |

お問合せください |

| WT2515-W1360-LFW |

1360 |

50 |

17.4 |

11.70 |

DXF | お問合せください |

お問合せください |

| WT2515-W1445-LFW |

1445 |

50 |

18.4 |

12.43 |

DXF | お問合せください |

お問合せください |

| WT2515-W1530-LFW |

1530 |

50 |

19.5 |

13.16 |

DXF | お問合せください |

お問合せください |

| WT2515-W1615-LFW |

1615 |

50 |

20.6 |

13.89 |

DXF | お問合せください |

お問合せください |

| WT2515-W1700-LFW |

1700 |

50 |

21.7 |

14.62 |

DXF | お問合せください |

お問合せください |

| WT2515-W1785-LFW |

1785 |

50 |

22.8 |

15.36 |

DXF | お問合せください |

お問合せください |

| WT2515-W1870-LFW |

1870 |

40 |

23.9 |

16.09 |

DXF | お問合せください |

お問合せください |

| WT2515-W1955-LFW |

1955 |

お問合せください |

25.0 |

16.82 |

DXF | お問合せください |

お問合せください |

| WT2515-W2040-LFW |

2040 |

お問合せください |

26.1 |

17.55 |

DXF | お問合せください |

お問合せください |

| WT2515-W2125-LFW |

2125 |

お問合せください |

27.2 |

18.28 |

DXF | お問合せください |

お問合せください |

| WT2515-W2210-LFW |

2210 |

お問合せください |

28.2 |

19.01 |

DXF | お問合せください |

お問合せください |

| WT2515-W2295-LFW |

2295 |

お問合せください |

29.3 |

19.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W2380-LFW |

2380 |

お問合せください |

30.4 |

20.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W2465-LFW |

2465 |

お問合せください |

31.5 |

21.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W2550-LFW |

2550 |

お問合せください |

32.6 |

21.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W2635-LFW |

2635 |

お問合せください |

33.7 |

22.67 |

DXF | お問合せください |

お問合せください |

| WT2515-W2720-LFW |

2720 |

お問合せください |

34.8 |

23.40 |

DXF | お問合せください |

お問合せください |

| WT2515-W2805-LFW |

2805 |

お問合せください |

35.9 |

24.13 |

DXF | お問合せください |

お問合せください |

| WT2515-W2890-LFW |

2890 |

お問合せください |

36.9 |

24.86 |

DXF | お問合せください |

お問合せください |

| WT2515-W2975-LFW |

2975 |

お問合せください |

38.0 |

25.59 |

DXF | お問合せください |

お問合せください |

| WT2515-W3060-LFW |

3060 |

お問合せください |

39.1 |

26.32 |

DXF | お問合せください |

お問合せください |

| WT2515-W3145-LFW |

3145 |

お問合せください |

40.2 |

27.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W3230-LFW |

3230 |

お問合せください |

41.3 |

27.78 |

DXF | お問合せください |

お問合せください |

|

低摩擦・耐摩耗  |

LFG |

グリーン |

△ |

12.8 |

8.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

能力線図を表示 |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2515-W85-LFG |

85 |

200 |

1.08 |

0.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W170-LFG |

170 |

200 |

2.17 |

1.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W255-LFG |

255 |

200 |

3.26 |

2.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W340-LFG |

340 |

200 |

4.35 |

2.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W425-LFG |

425 |

200 |

5.44 |

3.66 |

DXF | お問合せください |

お問合せください |

| WT2515-W510-LFG |

510 |

100 |

6.52 |

4.39 |

DXF | お問合せください |

お問合せください |

| WT2515-W595-LFG |

595 |

100 |

7.61 |

5.12 |

DXF | お問合せください |

お問合せください |

| WT2515-W680-LFG |

680 |

100 |

8.70 |

5.85 |

DXF | お問合せください |

お問合せください |

| WT2515-W765-LFG |

765 |

100 |

9.79 |

6.58 |

DXF | お問合せください |

お問合せください |

| WT2515-W850-LFG |

850 |

100 |

10.8 |

7.31 |

DXF | お問合せください |

お問合せください |

| WT2515-W935-LFG |

935 |

100 |

11.9 |

8.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W1020-LFG |

1020 |

80 |

13.0 |

8.78 |

DXF | お問合せください |

お問合せください |

| WT2515-W1105-LFG |

1105 |

80 |

14.1 |

9.51 |

DXF | お問合せください |

お問合せください |

| WT2515-W1190-LFG |

1190 |

80 |

15.2 |

10.24 |

DXF | お問合せください |

お問合せください |

| WT2515-W1275-LFG |

1275 |

50 |

16.3 |

10.97 |

DXF | お問合せください |

お問合せください |

| WT2515-W1360-LFG |

1360 |

50 |

17.4 |

11.70 |

DXF | お問合せください |

お問合せください |

| WT2515-W1445-LFG |

1445 |

50 |

18.4 |

12.43 |

DXF | お問合せください |

お問合せください |

| WT2515-W1530-LFG |

1530 |

50 |

19.5 |

13.16 |

DXF | お問合せください |

お問合せください |

| WT2515-W1615-LFG |

1615 |

50 |

20.6 |

13.89 |

DXF | お問合せください |

お問合せください |

| WT2515-W1700-LFG |

1700 |

50 |

21.7 |

14.62 |

DXF | お問合せください |

お問合せください |

| WT2515-W1785-LFG |

1785 |

50 |

22.8 |

15.36 |

DXF | お問合せください |

お問合せください |

| WT2515-W1870-LFG |

1870 |

40 |

23.9 |

16.09 |

DXF | お問合せください |

お問合せください |

| WT2515-W1955-LFG |

1955 |

お問合せください |

25.0 |

16.82 |

DXF | お問合せください |

お問合せください |

| WT2515-W2040-LFG |

2040 |

お問合せください |

26.1 |

17.55 |

DXF | お問合せください |

お問合せください |

| WT2515-W2125-LFG |

2125 |

お問合せください |

27.2 |

18.28 |

DXF | お問合せください |

お問合せください |

| WT2515-W2210-LFG |

2210 |

お問合せください |

28.2 |

19.01 |

DXF | お問合せください |

お問合せください |

| WT2515-W2295-LFG |

2295 |

お問合せください |

29.3 |

19.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W2380-LFG |

2380 |

お問合せください |

30.4 |

20.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W2465-LFG |

2465 |

お問合せください |

31.5 |

21.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W2550-LFG |

2550 |

お問合せください |

32.6 |

21.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W2635-LFG |

2635 |

お問合せください |

33.7 |

22.67 |

DXF | お問合せください |

お問合せください |

| WT2515-W2720-LFG |

2720 |

お問合せください |

34.8 |

23.40 |

DXF | お問合せください |

お問合せください |

| WT2515-W2805-LFG |

2805 |

お問合せください |

35.9 |

24.13 |

DXF | お問合せください |

お問合せください |

| WT2515-W2890-LFG |

2890 |

お問合せください |

36.9 |

24.86 |

DXF | お問合せください |

お問合せください |

| WT2515-W2975-LFG |

2975 |

お問合せください |

38.0 |

25.59 |

DXF | お問合せください |

お問合せください |

| WT2515-W3060-LFG |

3060 |

お問合せください |

39.1 |

26.32 |

DXF | お問合せください |

お問合せください |

| WT2515-W3145-LFG |

3145 |

お問合せください |

40.2 |

27.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W3230-LFG |

3230 |

お問合せください |

41.3 |

27.78 |

DXF | お問合せください |

お問合せください |

|

低摩擦・耐摩耗  |

LFB |

ブラウン |

△ |

12.8 |

8.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

能力線図を表示 |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2515-W85-LFB |

85 |

200 |

1.08 |

0.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W170-LFB |

170 |

200 |

2.17 |

1.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W255-LFB |

255 |

200 |

3.26 |

2.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W340-LFB |

340 |

200 |

4.35 |

2.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W425-LFB |

425 |

200 |

5.44 |

3.66 |

DXF | お問合せください |

お問合せください |

| WT2515-W510-LFB |

510 |

100 |

6.52 |

4.39 |

DXF | お問合せください |

お問合せください |

| WT2515-W595-LFB |

595 |

100 |

7.61 |

5.12 |

DXF | お問合せください |

お問合せください |

| WT2515-W680-LFB |

680 |

100 |

8.70 |

5.85 |

DXF | お問合せください |

お問合せください |

| WT2515-W765-LFB |

765 |

100 |

9.79 |

6.58 |

DXF | お問合せください |

お問合せください |

| WT2515-W850-LFB |

850 |

100 |

10.8 |

7.31 |

DXF | お問合せください |

お問合せください |

| WT2515-W935-LFB |

935 |

100 |

11.9 |

8.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W1020-LFB |

1020 |

80 |

13.0 |

8.78 |

DXF | お問合せください |

お問合せください |

| WT2515-W1105-LFB |

1105 |

80 |

14.1 |

9.51 |

DXF | お問合せください |

お問合せください |

| WT2515-W1190-LFB |

1190 |

80 |

15.2 |

10.24 |

DXF | お問合せください |

お問合せください |

| WT2515-W1275-LFB |

1275 |

50 |

16.3 |

10.97 |

DXF | お問合せください |

お問合せください |

| WT2515-W1360-LFB |

1360 |

50 |

17.4 |

11.70 |

DXF | お問合せください |

お問合せください |

| WT2515-W1445-LFB |

1445 |

50 |

18.4 |

12.43 |

DXF | お問合せください |

お問合せください |

| WT2515-W1530-LFB |

1530 |

50 |

19.5 |

13.16 |

DXF | お問合せください |

お問合せください |

| WT2515-W1615-LFB |

1615 |

50 |

20.6 |

13.89 |

DXF | お問合せください |

お問合せください |

| WT2515-W1700-LFB |

1700 |

50 |

21.7 |

14.62 |

DXF | お問合せください |

お問合せください |

| WT2515-W1785-LFB |

1785 |

50 |

22.8 |

15.36 |

DXF | お問合せください |

お問合せください |

| WT2515-W1870-LFB |

1870 |

40 |

23.9 |

16.09 |

DXF | お問合せください |

お問合せください |

| WT2515-W1955-LFB |

1955 |

お問合せください |

25.0 |

16.82 |

DXF | お問合せください |

お問合せください |

| WT2515-W2040-LFB |

2040 |

お問合せください |

26.1 |

17.55 |

DXF | お問合せください |

お問合せください |

| WT2515-W2125-LFB |

2125 |

お問合せください |

27.2 |

18.28 |

DXF | お問合せください |

お問合せください |

| WT2515-W2210-LFB |

2210 |

お問合せください |

28.2 |

19.01 |

DXF | お問合せください |

お問合せください |

| WT2515-W2295-LFB |

2295 |

お問合せください |

29.3 |

19.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W2380-LFB |

2380 |

お問合せください |

30.4 |

20.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W2465-LFB |

2465 |

お問合せください |

31.5 |

21.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W2550-LFB |

2550 |

お問合せください |

32.6 |

21.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W2635-LFB |

2635 |

お問合せください |

33.7 |

22.67 |

DXF | お問合せください |

お問合せください |

| WT2515-W2720-LFB |

2720 |

お問合せください |

34.8 |

23.40 |

DXF | お問合せください |

お問合せください |

| WT2515-W2805-LFB |

2805 |

お問合せください |

35.9 |

24.13 |

DXF | お問合せください |

お問合せください |

| WT2515-W2890-LFB |

2890 |

お問合せください |

36.9 |

24.86 |

DXF | お問合せください |

お問合せください |

| WT2515-W2975-LFB |

2975 |

お問合せください |

38.0 |

25.59 |

DXF | お問合せください |

お問合せください |

| WT2515-W3060-LFB |

3060 |

お問合せください |

39.1 |

26.32 |

DXF | お問合せください |

お問合せください |

| WT2515-W3145-LFB |

3145 |

お問合せください |

40.2 |

27.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W3230-LFB |

3230 |

お問合せください |

41.3 |

27.78 |

DXF | お問合せください |

お問合せください |

|

低摩擦・耐摩耗  |

CB |

ブルー |

○ |

12.8 |

8.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

能力線図を表示 |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2515-W85-CB |

85 |

200 |

1.08 |

0.74 |

DXF | ¥240 |

お問合せください |

| WT2515-W170-CB |

170 |

200 |

2.17 |

1.47 |

DXF | ¥296 |

お問合せください |

| WT2515-W255-CB |

255 |

200 |

3.26 |

2.20 |

DXF | ¥478 |

お問合せください |

| WT2515-W340-CB |

340 |

200 |

4.35 |

2.93 |

DXF | ¥598 |

お問合せください |

| WT2515-W425-CB |

425 |

200 |

5.44 |

3.66 |

DXF | ¥712 |

お問合せください |

| WT2515-W510-CB |

510 |

100 |

6.52 |

4.39 |

DXF | ¥832 |

お問合せください |

| WT2515-W595-CB |

595 |

100 |

7.61 |

5.12 |

DXF | ¥952 |

お問合せください |

| WT2515-W680-CB |

680 |

100 |

8.70 |

5.85 |

DXF | ¥1,070 |

お問合せください |

| WT2515-W765-CB |

765 |

100 |

9.79 |

6.58 |

DXF | ¥1,190 |

お問合せください |

| WT2515-W850-CB |

850 |

100 |

10.8 |

7.31 |

DXF | ¥1,310 |

お問合せください |

| WT2515-W935-CB |

935 |

100 |

11.9 |

8.05 |

DXF | ¥1,430 |

お問合せください |

| WT2515-W1020-CB |

1020 |

80 |

13.0 |

8.78 |

DXF | ¥1,550 |

お問合せください |

| WT2515-W1105-CB |

1105 |

80 |

14.1 |

9.51 |

DXF | ¥1,670 |

お問合せください |

| WT2515-W1190-CB |

1190 |

80 |

15.2 |

10.24 |

DXF | ¥1,780 |

お問合せください |

| WT2515-W1275-CB |

1275 |

50 |

16.3 |

10.97 |

DXF | ¥1,900 |

お問合せください |

| WT2515-W1360-CB |

1360 |

50 |

17.4 |

11.70 |

DXF | ¥2,020 |

お問合せください |

| WT2515-W1445-CB |

1445 |

50 |

18.4 |

12.43 |

DXF | ¥2,140 |

お問合せください |

| WT2515-W1530-CB |

1530 |

50 |

19.5 |

13.16 |

DXF | ¥2,240 |

お問合せください |

| WT2515-W1615-CB |

1615 |

50 |

20.6 |

13.89 |

DXF | ¥2,380 |

お問合せください |

| WT2515-W1700-CB |

1700 |

50 |

21.7 |

14.62 |

DXF | お問合せください |

お問合せください |

| WT2515-W1785-CB |

1785 |

50 |

22.8 |

15.36 |

DXF | お問合せください |

お問合せください |

| WT2515-W1870-CB |

1870 |

40 |

23.9 |

16.09 |

DXF | お問合せください |

お問合せください |

| WT2515-W1955-CB |

1955 |

お問合せください |

25.0 |

16.82 |

DXF | お問合せください |

お問合せください |

| WT2515-W2040-CB |

2040 |

お問合せください |

26.1 |

17.55 |

DXF | お問合せください |

お問合せください |

| WT2515-W2125-CB |

2125 |

お問合せください |

27.2 |

18.28 |

DXF | お問合せください |

お問合せください |

| WT2515-W2210-CB |

2210 |

お問合せください |

28.2 |

19.01 |

DXF | お問合せください |

お問合せください |

| WT2515-W2295-CB |

2295 |

お問合せください |

29.3 |

19.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W2380-CB |

2380 |

お問合せください |

30.4 |

20.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W2465-CB |

2465 |

お問合せください |

31.5 |

21.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W2550-CB |

2550 |

お問合せください |

32.6 |

21.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W2635-CB |

2635 |

お問合せください |

33.7 |

22.67 |

DXF | お問合せください |

お問合せください |

| WT2515-W2720-CB |

2720 |

お問合せください |

34.8 |

23.40 |

DXF | お問合せください |

お問合せください |

| WT2515-W2805-CB |

2805 |

お問合せください |

35.9 |

24.13 |

DXF | お問合せください |

お問合せください |

| WT2515-W2890-CB |

2890 |

お問合せください |

36.9 |

24.86 |

DXF | お問合せください |

お問合せください |

| WT2515-W2975-CB |

2975 |

お問合せください |

38.0 |

25.59 |

DXF | お問合せください |

お問合せください |

| WT2515-W3060-CB |

3060 |

お問合せください |

39.1 |

26.32 |

DXF | お問合せください |

お問合せください |

| WT2515-W3145-CB |

3145 |

お問合せください |

40.2 |

27.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W3230-CB |

3230 |

お問合せください |

41.3 |

27.78 |

DXF | お問合せください |

お問合せください |

|

超低摩擦・耐摩耗  |

ALF |

ライトブルー |

○ |

12.8 |

8.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

能力線図を表示 |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2515-W85-ALF |

85 |

200 |

1.08 |

0.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W170-ALF |

170 |

200 |

2.17 |

1.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W255-ALF |

255 |

200 |

3.26 |

2.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W340-ALF |

340 |

200 |

4.35 |

2.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W425-ALF |

425 |

200 |

5.44 |

3.66 |

DXF | お問合せください |

お問合せください |

| WT2515-W510-ALF |

510 |

100 |

6.52 |

4.39 |

DXF | お問合せください |

お問合せください |

| WT2515-W595-ALF |

595 |

100 |

7.61 |

5.12 |

DXF | お問合せください |

お問合せください |

| WT2515-W680-ALF |

680 |

100 |

8.70 |

5.85 |

DXF | お問合せください |

お問合せください |

| WT2515-W765-ALF |

765 |

100 |

9.79 |

6.58 |

DXF | お問合せください |

お問合せください |

| WT2515-W850-ALF |

850 |

100 |

10.8 |

7.31 |

DXF | お問合せください |

お問合せください |

| WT2515-W935-ALF |

935 |

100 |

11.9 |

8.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W1020-ALF |

1020 |

80 |

13.0 |

8.78 |

DXF | お問合せください |

お問合せください |

| WT2515-W1105-ALF |

1105 |

80 |

14.1 |

9.51 |

DXF | お問合せください |

お問合せください |

| WT2515-W1190-ALF |

1190 |

80 |

15.2 |

10.24 |

DXF | お問合せください |

お問合せください |

| WT2515-W1275-ALF |

1275 |

50 |

16.3 |

10.97 |

DXF | お問合せください |

お問合せください |

| WT2515-W1360-ALF |

1360 |

50 |

17.4 |

11.70 |

DXF | お問合せください |

お問合せください |

| WT2515-W1445-ALF |

1445 |

50 |

18.4 |

12.43 |

DXF | お問合せください |

お問合せください |

| WT2515-W1530-ALF |

1530 |

50 |

19.5 |

13.16 |

DXF | お問合せください |

お問合せください |

| WT2515-W1615-ALF |

1615 |

50 |

20.6 |

13.89 |

DXF | お問合せください |

お問合せください |

| WT2515-W1700-ALF |

1700 |

50 |

21.7 |

14.62 |

DXF | お問合せください |

お問合せください |

| WT2515-W1785-ALF |

1785 |

50 |

22.8 |

15.36 |

DXF | お問合せください |

お問合せください |

| WT2515-W1870-ALF |

1870 |

40 |

23.9 |

16.09 |

DXF | お問合せください |

お問合せください |

| WT2515-W1955-ALF |

1955 |

お問合せください |

25.0 |

16.82 |

DXF | お問合せください |

お問合せください |

| WT2515-W2040-ALF |

2040 |

お問合せください |

26.1 |

17.55 |

DXF | お問合せください |

お問合せください |

| WT2515-W2125-ALF |

2125 |

お問合せください |

27.2 |

18.28 |

DXF | お問合せください |

お問合せください |

| WT2515-W2210-ALF |

2210 |

お問合せください |

28.2 |

19.01 |

DXF | お問合せください |

お問合せください |

| WT2515-W2295-ALF |

2295 |

お問合せください |

29.3 |

19.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W2380-ALF |

2380 |

お問合せください |

30.4 |

20.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W2465-ALF |

2465 |

お問合せください |

31.5 |

21.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W2550-ALF |

2550 |

お問合せください |

32.6 |

21.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W2635-ALF |

2635 |

お問合せください |

33.7 |

22.67 |

DXF | お問合せください |

お問合せください |

| WT2515-W2720-ALF |

2720 |

お問合せください |

34.8 |

23.40 |

DXF | お問合せください |

お問合せください |

| WT2515-W2805-ALF |

2805 |

お問合せください |

35.9 |

24.13 |

DXF | お問合せください |

お問合せください |

| WT2515-W2890-ALF |

2890 |

お問合せください |

36.9 |

24.86 |

DXF | お問合せください |

お問合せください |

| WT2515-W2975-ALF |

2975 |

お問合せください |

38.0 |

25.59 |

DXF | お問合せください |

お問合せください |

| WT2515-W3060-ALF |

3060 |

お問合せください |

39.1 |

26.32 |

DXF | お問合せください |

お問合せください |

| WT2515-W3145-ALF |

3145 |

お問合せください |

40.2 |

27.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W3230-ALF |

3230 |

お問合せください |

41.3 |

27.78 |

DXF | お問合せください |

お問合せください |

|

低摩擦  |

NLF |

ダークグレー |

△ |

12.8 |

8.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

能力線図を表示 |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2515-W85-NLF |

85 |

200 |

1.08 |

0.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W170-NLF |

170 |

200 |

2.17 |

1.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W255-NLF |

255 |

200 |

3.26 |

2.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W340-NLF |

340 |

200 |

4.35 |

2.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W425-NLF |

425 |

200 |

5.44 |

3.66 |

DXF | お問合せください |

お問合せください |

| WT2515-W510-NLF |

510 |

100 |

6.52 |

4.39 |

DXF | お問合せください |

お問合せください |

| WT2515-W595-NLF |

595 |

100 |

7.61 |

5.12 |

DXF | お問合せください |

お問合せください |

| WT2515-W680-NLF |

680 |

100 |

8.70 |

5.85 |

DXF | お問合せください |

お問合せください |

| WT2515-W765-NLF |

765 |

100 |

9.79 |

6.58 |

DXF | お問合せください |

お問合せください |

| WT2515-W850-NLF |

850 |

100 |

10.8 |

7.31 |

DXF | お問合せください |

お問合せください |

| WT2515-W935-NLF |

935 |

100 |

11.9 |

8.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W1020-NLF |

1020 |

80 |

13.0 |

8.78 |

DXF | お問合せください |

お問合せください |

| WT2515-W1105-NLF |

1105 |

80 |

14.1 |

9.51 |

DXF | お問合せください |

お問合せください |

| WT2515-W1190-NLF |

1190 |

80 |

15.2 |

10.24 |

DXF | お問合せください |

お問合せください |

| WT2515-W1275-NLF |

1275 |

50 |

16.3 |

10.97 |

DXF | お問合せください |

お問合せください |

| WT2515-W1360-NLF |

1360 |

50 |

17.4 |

11.70 |

DXF | お問合せください |

お問合せください |

| WT2515-W1445-NLF |

1445 |

50 |

18.4 |

12.43 |

DXF | お問合せください |

お問合せください |

| WT2515-W1530-NLF |

1530 |

50 |

19.5 |

13.16 |

DXF | お問合せください |

お問合せください |

| WT2515-W1615-NLF |

1615 |

50 |

20.6 |

13.89 |

DXF | お問合せください |

お問合せください |

| WT2515-W1700-NLF |

1700 |

50 |

21.7 |

14.62 |

DXF | お問合せください |

お問合せください |

| WT2515-W1785-NLF |

1785 |

50 |

22.8 |

15.36 |

DXF | お問合せください |

お問合せください |

| WT2515-W1870-NLF |

1870 |

40 |

23.9 |

16.09 |

DXF | お問合せください |

お問合せください |

| WT2515-W1955-NLF |

1955 |

お問合せください |

25.0 |

16.82 |

DXF | お問合せください |

お問合せください |

| WT2515-W2040-NLF |

2040 |

お問合せください |

26.1 |

17.55 |

DXF | お問合せください |

お問合せください |

| WT2515-W2125-NLF |

2125 |

お問合せください |

27.2 |

18.28 |

DXF | お問合せください |

お問合せください |

| WT2515-W2210-NLF |

2210 |

お問合せください |

28.2 |

19.01 |

DXF | お問合せください |

お問合せください |

| WT2515-W2295-NLF |

2295 |

お問合せください |

29.3 |

19.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W2380-NLF |

2380 |

お問合せください |

30.4 |

20.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W2465-NLF |

2465 |

お問合せください |

31.5 |

21.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W2550-NLF |

2550 |

お問合せください |

32.6 |

21.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W2635-NLF |

2635 |

お問合せください |

33.7 |

22.67 |

DXF | お問合せください |

お問合せください |

| WT2515-W2720-NLF |

2720 |

お問合せください |

34.8 |

23.40 |

DXF | お問合せください |

お問合せください |

| WT2515-W2805-NLF |

2805 |

お問合せください |

35.9 |

24.13 |

DXF | お問合せください |

お問合せください |

| WT2515-W2890-NLF |

2890 |

お問合せください |

36.9 |

24.86 |

DXF | お問合せください |

お問合せください |

| WT2515-W2975-NLF |

2975 |

お問合せください |

38.0 |

25.59 |

DXF | お問合せください |

お問合せください |

| WT2515-W3060-NLF |

3060 |

お問合せください |

39.1 |

26.32 |

DXF | お問合せください |

お問合せください |

| WT2515-W3145-NLF |

3145 |

お問合せください |

40.2 |

27.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W3230-NLF |

3230 |

お問合せください |

41.3 |

27.78 |

DXF | お問合せください |

お問合せください |

|

低摩擦  |

WR |

ダークグリーン |

△ |

12.8 |

8.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

能力線図を表示 |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2515-W85-WR |

85 |

200 |

1.08 |

0.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W170-WR |

170 |

200 |

2.17 |

1.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W255-WR |

255 |

200 |

3.26 |

2.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W340-WR |

340 |

200 |

4.35 |

2.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W425-WR |

425 |

200 |

5.44 |

3.66 |

DXF | お問合せください |

お問合せください |

| WT2515-W510-WR |

510 |

100 |

6.52 |

4.39 |

DXF | お問合せください |

お問合せください |

| WT2515-W595-WR |

595 |

100 |

7.61 |

5.12 |

DXF | お問合せください |

お問合せください |

| WT2515-W680-WR |

680 |

100 |

8.70 |

5.85 |

DXF | お問合せください |

お問合せください |

| WT2515-W765-WR |

765 |

100 |

9.79 |

6.58 |

DXF | お問合せください |

お問合せください |

| WT2515-W850-WR |

850 |

100 |

10.8 |

7.31 |

DXF | お問合せください |

お問合せください |

| WT2515-W935-WR |

935 |

100 |

11.9 |

8.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W1020-WR |

1020 |

80 |

13.0 |

8.78 |

DXF | お問合せください |

お問合せください |

| WT2515-W1105-WR |

1105 |

80 |

14.1 |

9.51 |

DXF | お問合せください |

お問合せください |

| WT2515-W1190-WR |

1190 |

80 |

15.2 |

10.24 |

DXF | お問合せください |

お問合せください |

| WT2515-W1275-WR |

1275 |

50 |

16.3 |

10.97 |

DXF | お問合せください |

お問合せください |

| WT2515-W1360-WR |

1360 |

50 |

17.4 |

11.70 |

DXF | お問合せください |

お問合せください |

| WT2515-W1445-WR |

1445 |

50 |

18.4 |

12.43 |

DXF | お問合せください |

お問合せください |

| WT2515-W1530-WR |

1530 |

50 |

19.5 |

13.16 |

DXF | お問合せください |

お問合せください |

| WT2515-W1615-WR |

1615 |

50 |

20.6 |

13.89 |

DXF | お問合せください |

お問合せください |

| WT2515-W1700-WR |

1700 |

50 |

21.7 |

14.62 |

DXF | お問合せください |

お問合せください |

| WT2515-W1785-WR |

1785 |

50 |

22.8 |

15.36 |

DXF | お問合せください |

お問合せください |

| WT2515-W1870-WR |

1870 |

40 |

23.9 |

16.09 |

DXF | お問合せください |

お問合せください |

| WT2515-W1955-WR |

1955 |

お問合せください |

25.0 |

16.82 |

DXF | お問合せください |

お問合せください |

| WT2515-W2040-WR |

2040 |

お問合せください |

26.1 |

17.55 |

DXF | お問合せください |

お問合せください |

| WT2515-W2125-WR |

2125 |

お問合せください |

27.2 |

18.28 |

DXF | お問合せください |

お問合せください |

| WT2515-W2210-WR |

2210 |

お問合せください |

28.2 |

19.01 |

DXF | お問合せください |

お問合せください |

| WT2515-W2295-WR |

2295 |

お問合せください |

29.3 |

19.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W2380-WR |

2380 |

お問合せください |

30.4 |

20.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W2465-WR |

2465 |

お問合せください |

31.5 |

21.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W2550-WR |

2550 |

お問合せください |

32.6 |

21.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W2635-WR |

2635 |

お問合せください |

33.7 |

22.67 |

DXF | お問合せください |

お問合せください |

| WT2515-W2720-WR |

2720 |

お問合せください |

34.8 |

23.40 |

DXF | お問合せください |

お問合せください |

| WT2515-W2805-WR |

2805 |

お問合せください |

35.9 |

24.13 |

DXF | お問合せください |

お問合せください |

| WT2515-W2890-WR |

2890 |

お問合せください |

36.9 |

24.86 |

DXF | お問合せください |

お問合せください |

| WT2515-W2975-WR |

2975 |

お問合せください |

38.0 |

25.59 |

DXF | お問合せください |

お問合せください |

| WT2515-W3060-WR |

3060 |

お問合せください |

39.1 |

26.32 |

DXF | お問合せください |

お問合せください |

| WT2515-W3145-WR |

3145 |

お問合せください |

40.2 |

27.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W3230-WR |

3230 |

お問合せください |

41.3 |

27.78 |

DXF | お問合せください |

お問合せください |

|

高機能シリーズ

仕様

( クリックで仕様毎の クリックで仕様毎の

詳細を表示します。) |

仕様記号 |

外観色 |

対応 |

最大

許容張力

kN/m |

チェーン

概略質量

kg/m2 |

許容速度

m/min |

使用温度範囲

゚C |

ピン材質 |

プラグ材質 |

プラグ外観色 |

能力線図 |

| 潤滑有 |

潤滑なし |

低摩擦・耐摩耗  |

HG |

ネイビーブルー |

○ |

12.8 |

8.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

能力線図を表示 |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2515-W85-HG |

85 |

200 |

1.08 |

0.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W170-HG |

170 |

200 |

2.17 |

1.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W255-HG |

255 |

200 |

3.26 |

2.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W340-HG |

340 |

200 |

4.35 |

2.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W425-HG |

425 |

200 |

5.44 |

3.66 |

DXF | お問合せください |

お問合せください |

| WT2515-W510-HG |

510 |

100 |

6.52 |

4.39 |

DXF | お問合せください |

お問合せください |

| WT2515-W595-HG |

595 |

100 |

7.61 |

5.12 |

DXF | お問合せください |

お問合せください |

| WT2515-W680-HG |

680 |

100 |

8.70 |

5.85 |

DXF | お問合せください |

お問合せください |

| WT2515-W765-HG |

765 |

100 |

9.79 |

6.58 |

DXF | お問合せください |

お問合せください |

| WT2515-W850-HG |

850 |

100 |

10.8 |

7.31 |

DXF | お問合せください |

お問合せください |

| WT2515-W935-HG |

935 |

100 |

11.9 |

8.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W1020-HG |

1020 |

80 |

13.0 |

8.78 |

DXF | お問合せください |

お問合せください |

| WT2515-W1105-HG |

1105 |

80 |

14.1 |

9.51 |

DXF | お問合せください |

お問合せください |

| WT2515-W1190-HG |

1190 |

80 |

15.2 |

10.24 |

DXF | お問合せください |

お問合せください |

| WT2515-W1275-HG |

1275 |

50 |

16.3 |

10.97 |

DXF | お問合せください |

お問合せください |

| WT2515-W1360-HG |

1360 |

50 |

17.4 |

11.70 |

DXF | お問合せください |

お問合せください |

| WT2515-W1445-HG |

1445 |

50 |

18.4 |

12.43 |

DXF | お問合せください |

お問合せください |

| WT2515-W1530-HG |

1530 |

50 |

19.5 |

13.16 |

DXF | お問合せください |

お問合せください |

| WT2515-W1615-HG |

1615 |

50 |

20.6 |

13.89 |

DXF | お問合せください |

お問合せください |

| WT2515-W1700-HG |

1700 |

50 |

21.7 |

14.62 |

DXF | お問合せください |

お問合せください |

| WT2515-W1785-HG |

1785 |

50 |

22.8 |

15.36 |

DXF | お問合せください |

お問合せください |

| WT2515-W1870-HG |

1870 |

40 |

23.9 |

16.09 |

DXF | お問合せください |

お問合せください |

| WT2515-W1955-HG |

1955 |

お問合せください |

25.0 |

16.82 |

DXF | お問合せください |

お問合せください |

| WT2515-W2040-HG |

2040 |

お問合せください |

26.1 |

17.55 |

DXF | お問合せください |

お問合せください |

| WT2515-W2125-HG |

2125 |

お問合せください |

27.2 |

18.28 |

DXF | お問合せください |

お問合せください |

| WT2515-W2210-HG |

2210 |

お問合せください |

28.2 |

19.01 |

DXF | お問合せください |

お問合せください |

| WT2515-W2295-HG |

2295 |

お問合せください |

29.3 |

19.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W2380-HG |

2380 |

お問合せください |

30.4 |

20.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W2465-HG |

2465 |

お問合せください |

31.5 |

21.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W2550-HG |

2550 |

お問合せください |

32.6 |

21.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W2635-HG |

2635 |

お問合せください |

33.7 |

22.67 |

DXF | お問合せください |

お問合せください |

| WT2515-W2720-HG |

2720 |

お問合せください |

34.8 |

23.40 |

DXF | お問合せください |

お問合せください |

| WT2515-W2805-HG |

2805 |

お問合せください |

35.9 |

24.13 |

DXF | お問合せください |

お問合せください |

| WT2515-W2890-HG |

2890 |

お問合せください |

36.9 |

24.86 |

DXF | お問合せください |

お問合せください |

| WT2515-W2975-HG |

2975 |

お問合せください |

38.0 |

25.59 |

DXF | お問合せください |

お問合せください |

| WT2515-W3060-HG |

3060 |

お問合せください |

39.1 |

26.32 |

DXF | お問合せください |

お問合せください |

| WT2515-W3145-HG |

3145 |

お問合せください |

40.2 |

27.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W3230-HG |

3230 |

お問合せください |

41.3 |

27.78 |

DXF | お問合せください |

お問合せください |

|

高温  |

HTW |

ホワイト |

△ |

6.4 |

5.7 |

50 |

50 |

5~105 |

ポリプロピレン |

ポリプロピレン |

ブルー |

- |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2515-W85-HTW |

85 |

200 |

0.54 |

0.49 |

DXF | お問合せください |

お問合せください |

| WT2515-W170-HTW |

170 |

200 |

1.08 |

0.97 |

DXF | お問合せください |

お問合せください |

| WT2515-W255-HTW |

255 |

200 |

1.63 |

1.46 |

DXF | お問合せください |

お問合せください |

| WT2515-W340-HTW |

340 |

200 |

2.17 |

1.94 |

DXF | お問合せください |

お問合せください |

| WT2515-W425-HTW |

425 |

200 |

2.72 |

2.43 |

DXF | お問合せください |

お問合せください |

| WT2515-W510-HTW |

510 |

100 |

3.26 |

2.91 |

DXF | お問合せください |

お問合せください |

| WT2515-W595-HTW |

595 |

100 |

3.80 |

3.40 |

DXF | お問合せください |

お問合せください |

| WT2515-W680-HTW |

680 |

100 |

4.35 |

3.88 |

DXF | お問合せください |

お問合せください |

| WT2515-W765-HTW |

765 |

100 |

4.89 |

4.36 |

DXF | お問合せください |

お問合せください |

| WT2515-W850-HTW |

850 |

100 |

5.44 |

4.85 |

DXF | お問合せください |

お問合せください |

| WT2515-W935-HTW |

935 |

100 |

5.98 |

5.33 |

DXF | お問合せください |

お問合せください |

| WT2515-W1020-HTW |

1020 |

80 |

6.52 |

5.82 |

DXF | お問合せください |

お問合せください |

| WT2515-W1105-HTW |

1105 |

80 |

7.07 |

6.30 |

DXF | お問合せください |

お問合せください |

| WT2515-W1190-HTW |

1190 |

80 |

7.61 |

6.79 |

DXF | お問合せください |

お問合せください |

| WT2515-W1275-HTW |

1275 |

50 |

8.16 |

7.27 |

DXF | お問合せください |

お問合せください |

| WT2515-W1360-HTW |

1360 |

50 |

8.70 |

7.76 |

DXF | お問合せください |

お問合せください |

| WT2515-W1445-HTW |

1445 |

50 |

9.24 |

8.24 |

DXF | お問合せください |

お問合せください |

| WT2515-W1530-HTW |

1530 |

50 |

9.79 |

8.73 |

DXF | お問合せください |

お問合せください |

| WT2515-W1615-HTW |

1615 |

50 |

10.3 |

9.21 |

DXF | お問合せください |

お問合せください |

| WT2515-W1700-HTW |

1700 |

50 |

10.8 |

9.69 |

DXF | お問合せください |

お問合せください |

| WT2515-W1785-HTW |

1785 |

50 |

11.4 |

10.18 |

DXF | お問合せください |

お問合せください |

| WT2515-W1870-HTW |

1870 |

40 |

11.9 |

10.66 |

DXF | お問合せください |

お問合せください |

| WT2515-W1955-HTW |

1955 |

お問合せください |

12.5 |

11.15 |

DXF | お問合せください |

お問合せください |

| WT2515-W2040-HTW |

2040 |

お問合せください |

13.0 |

11.63 |

DXF | お問合せください |

お問合せください |

| WT2515-W2125-HTW |

2125 |

お問合せください |

13.6 |

12.12 |

DXF | お問合せください |

お問合せください |

| WT2515-W2210-HTW |

2210 |

お問合せください |

14.1 |

12.60 |

DXF | お問合せください |

お問合せください |

| WT2515-W2295-HTW |

2295 |

お問合せください |

14.6 |

13.09 |

DXF | お問合せください |

お問合せください |

| WT2515-W2380-HTW |

2380 |

お問合せください |

15.2 |

13.57 |

DXF | お問合せください |

お問合せください |

| WT2515-W2465-HTW |

2465 |

お問合せください |

15.7 |

14.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W2550-HTW |

2550 |

お問合せください |

16.3 |

14.54 |

DXF | お問合せください |

お問合せください |

| WT2515-W2635-HTW |

2635 |

お問合せください |

16.8 |

15.02 |

DXF | お問合せください |

お問合せください |

| WT2515-W2720-HTW |

2720 |

お問合せください |

17.4 |

15.51 |

DXF | お問合せください |

お問合せください |

| WT2515-W2805-HTW |

2805 |

お問合せください |

17.9 |

15.99 |

DXF | お問合せください |

お問合せください |

| WT2515-W2890-HTW |

2890 |

お問合せください |

18.4 |

16.48 |

DXF | お問合せください |

お問合せください |

| WT2515-W2975-HTW |

2975 |

お問合せください |

19.0 |

16.96 |

DXF | お問合せください |

お問合せください |

| WT2515-W3060-HTW |

3060 |

お問合せください |

19.5 |

17.45 |

DXF | お問合せください |

お問合せください |

| WT2515-W3145-HTW |

3145 |

お問合せください |

20.1 |

17.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W3230-HTW |

3230 |

お問合せください |

20.6 |

18.42 |

DXF | お問合せください |

お問合せください |

|

導電  |

E |

ブラック |

△ |

9.0 |

8.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

- |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2515-W85-E |

85 |

200 |

0.76 |

0.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W170-E |

170 |

200 |

1.53 |

1.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W255-E |

255 |

200 |

2.29 |

2.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W340-E |

340 |

200 |

3.06 |

2.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W425-E |

425 |

200 |

3.82 |

3.66 |

DXF | お問合せください |

お問合せください |

| WT2515-W510-E |

510 |

100 |

4.59 |

4.39 |

DXF | お問合せください |

お問合せください |

| WT2515-W595-E |

595 |

100 |

5.35 |

5.12 |

DXF | お問合せください |

お問合せください |

| WT2515-W680-E |

680 |

100 |

6.12 |

5.85 |

DXF | お問合せください |

お問合せください |

| WT2515-W765-E |

765 |

100 |

6.88 |

6.58 |

DXF | お問合せください |

お問合せください |

| WT2515-W850-E |

850 |

100 |

7.65 |

7.31 |

DXF | お問合せください |

お問合せください |

| WT2515-W935-E |

935 |

100 |

8.41 |

8.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W1020-E |

1020 |

80 |

9.18 |

8.78 |

DXF | お問合せください |

お問合せください |

| WT2515-W1105-E |

1105 |

80 |

9.94 |

9.51 |

DXF | お問合せください |

お問合せください |

| WT2515-W1190-E |

1190 |

80 |

10.7 |

10.24 |

DXF | お問合せください |

お問合せください |

| WT2515-W1275-E |

1275 |

50 |

11.4 |

10.97 |

DXF | お問合せください |

お問合せください |

| WT2515-W1360-E |

1360 |

50 |

12.2 |

11.70 |

DXF | お問合せください |

お問合せください |

| WT2515-W1445-E |

1445 |

50 |

13.0 |

12.43 |

DXF | お問合せください |

お問合せください |

| WT2515-W1530-E |

1530 |

50 |

13.7 |

13.16 |

DXF | お問合せください |

お問合せください |

| WT2515-W1615-E |

1615 |

50 |

14.5 |

13.89 |

DXF | お問合せください |

お問合せください |

| WT2515-W1700-E |

1700 |

50 |

15.3 |

14.62 |

DXF | お問合せください |

お問合せください |

| WT2515-W1785-E |

1785 |

50 |

16.0 |

15.36 |

DXF | お問合せください |

お問合せください |

| WT2515-W1870-E |

1870 |

40 |

16.8 |

16.09 |

DXF | お問合せください |

お問合せください |

| WT2515-W1955-E |

1955 |

お問合せください |

17.5 |

16.82 |

DXF | お問合せください |

お問合せください |

| WT2515-W2040-E |

2040 |

お問合せください |

18.3 |

17.55 |

DXF | お問合せください |

お問合せください |

| WT2515-W2125-E |

2125 |

お問合せください |

19.1 |

18.28 |

DXF | お問合せください |

お問合せください |

| WT2515-W2210-E |

2210 |

お問合せください |

19.8 |

19.01 |

DXF | お問合せください |

お問合せください |

| WT2515-W2295-E |

2295 |

お問合せください |

20.6 |

19.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W2380-E |

2380 |

お問合せください |

21.4 |

20.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W2465-E |

2465 |

お問合せください |

22.1 |

21.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W2550-E |

2550 |

お問合せください |

22.9 |

21.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W2635-E |

2635 |

お問合せください |

23.7 |

22.67 |

DXF | お問合せください |

お問合せください |

| WT2515-W2720-E |

2720 |

お問合せください |

24.4 |

23.40 |

DXF | お問合せください |

お問合せください |

| WT2515-W2805-E |

2805 |

お問合せください |

25.2 |

24.13 |

DXF | お問合せください |

お問合せください |

| WT2515-W2890-E |

2890 |

お問合せください |

26.0 |

24.86 |

DXF | お問合せください |

お問合せください |

| WT2515-W2975-E |

2975 |

お問合せください |

26.7 |

25.59 |

DXF | お問合せください |

お問合せください |

| WT2515-W3060-E |

3060 |

お問合せください |

27.5 |

26.32 |

DXF | お問合せください |

お問合せください |

| WT2515-W3145-E |

3145 |

お問合せください |

28.3 |

27.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W3230-E |

3230 |

お問合せください |

29.0 |

27.78 |

DXF | お問合せください |

お問合せください |

|

抗菌・防カビ  |

MWS |

クリーム |

△ |

12.8 |

8.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

- |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2515-W85-MWS |

85 |

200 |

1.08 |

0.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W170-MWS |

170 |

200 |

2.17 |

1.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W255-MWS |

255 |

200 |

3.26 |

2.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W340-MWS |

340 |

200 |

4.35 |

2.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W425-MWS |

425 |

200 |

5.44 |

3.66 |

DXF | お問合せください |

お問合せください |

| WT2515-W510-MWS |

510 |

100 |

6.52 |

4.39 |

DXF | お問合せください |

お問合せください |

| WT2515-W595-MWS |

595 |

100 |

7.61 |

5.12 |

DXF | お問合せください |

お問合せください |

| WT2515-W680-MWS |

680 |

100 |

8.70 |

5.85 |

DXF | お問合せください |

お問合せください |

| WT2515-W765-MWS |

765 |

100 |

9.79 |

6.58 |

DXF | お問合せください |

お問合せください |

| WT2515-W850-MWS |

850 |

100 |

10.8 |

7.31 |

DXF | お問合せください |

お問合せください |

| WT2515-W935-MWS |

935 |

100 |

11.9 |

8.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W1020-MWS |

1020 |

80 |

13.0 |

8.78 |

DXF | お問合せください |

お問合せください |

| WT2515-W1105-MWS |

1105 |

80 |

14.1 |

9.51 |

DXF | お問合せください |

お問合せください |

| WT2515-W1190-MWS |

1190 |

80 |

15.2 |

10.24 |

DXF | お問合せください |

お問合せください |

| WT2515-W1275-MWS |

1275 |

50 |

16.3 |

10.97 |

DXF | お問合せください |

お問合せください |

| WT2515-W1360-MWS |

1360 |

50 |

17.4 |

11.70 |

DXF | お問合せください |

お問合せください |

| WT2515-W1445-MWS |

1445 |

50 |

18.4 |

12.43 |

DXF | お問合せください |

お問合せください |

| WT2515-W1530-MWS |

1530 |

50 |

19.5 |

13.16 |

DXF | お問合せください |

お問合せください |

| WT2515-W1615-MWS |

1615 |

50 |

20.6 |

13.89 |

DXF | お問合せください |

お問合せください |

| WT2515-W1700-MWS |

1700 |

50 |

21.7 |

14.62 |

DXF | お問合せください |

お問合せください |

| WT2515-W1785-MWS |

1785 |

50 |

22.8 |

15.36 |

DXF | お問合せください |

お問合せください |

| WT2515-W1870-MWS |

1870 |

40 |

23.9 |

16.09 |

DXF | お問合せください |

お問合せください |

| WT2515-W1955-MWS |

1955 |

お問合せください |

25.0 |

16.82 |

DXF | お問合せください |

お問合せください |

| WT2515-W2040-MWS |

2040 |

お問合せください |

26.1 |

17.55 |

DXF | お問合せください |

お問合せください |

| WT2515-W2125-MWS |

2125 |

お問合せください |

27.2 |

18.28 |

DXF | お問合せください |

お問合せください |

| WT2515-W2210-MWS |

2210 |

お問合せください |

28.2 |

19.01 |

DXF | お問合せください |

お問合せください |

| WT2515-W2295-MWS |

2295 |

お問合せください |

29.3 |

19.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W2380-MWS |

2380 |

お問合せください |

30.4 |

20.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W2465-MWS |

2465 |

お問合せください |

31.5 |

21.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W2550-MWS |

2550 |

お問合せください |

32.6 |

21.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W2635-MWS |

2635 |

お問合せください |

33.7 |

22.67 |

DXF | お問合せください |

お問合せください |

| WT2515-W2720-MWS |

2720 |

お問合せください |

34.8 |

23.40 |

DXF | お問合せください |

お問合せください |

| WT2515-W2805-MWS |

2805 |

お問合せください |

35.9 |

24.13 |

DXF | お問合せください |

お問合せください |

| WT2515-W2890-MWS |

2890 |

お問合せください |

36.9 |

24.86 |

DXF | お問合せください |

お問合せください |

| WT2515-W2975-MWS |

2975 |

お問合せください |

38.0 |

25.59 |

DXF | お問合せください |

お問合せください |

| WT2515-W3060-MWS |

3060 |

お問合せください |

39.1 |

26.32 |

DXF | お問合せください |

お問合せください |

| WT2515-W3145-MWS |

3145 |

お問合せください |

40.2 |

27.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W3230-MWS |

3230 |

お問合せください |

41.3 |

27.78 |

DXF | お問合せください |

お問合せください |

|

中摩擦

(ドライ条件専用)  |

MF |

イエロー |

△ |

9.47 |

8.6 |

- |

50 |

-20~80 |

特殊エンプラ |

ポリアセタール |

イエロー |

- |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2515-W85-MF |

85 |

200 |

0.80 |

0.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W170-MF |

170 |

200 |

1.60 |

1.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W255-MF |

255 |

200 |

2.41 |

2.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W340-MF |

340 |

200 |

3.21 |

2.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W425-MF |

425 |

200 |

4.02 |

3.66 |

DXF | お問合せください |

お問合せください |

| WT2515-W510-MF |

510 |

100 |

4.82 |

4.39 |

DXF | お問合せください |

お問合せください |

| WT2515-W595-MF |

595 |

100 |

5.63 |

5.12 |

DXF | お問合せください |

お問合せください |

| WT2515-W680-MF |

680 |

100 |

6.43 |

5.85 |

DXF | お問合せください |

お問合せください |

| WT2515-W765-MF |

765 |

100 |

7.24 |

6.58 |

DXF | お問合せください |

お問合せください |

| WT2515-W850-MF |

850 |

100 |

8.04 |

7.31 |

DXF | お問合せください |

お問合せください |

| WT2515-W935-MF |

935 |

100 |

8.85 |

8.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W1020-MF |

1020 |

80 |

9.65 |

8.78 |

DXF | お問合せください |

お問合せください |

| WT2515-W1105-MF |

1105 |

80 |

10.4 |

9.51 |

DXF | お問合せください |

お問合せください |

| WT2515-W1190-MF |

1190 |

80 |

11.2 |

10.24 |

DXF | お問合せください |

お問合せください |

| WT2515-W1275-MF |

1275 |

50 |

12.0 |

10.97 |

DXF | お問合せください |

お問合せください |

| WT2515-W1360-MF |

1360 |

50 |

12.8 |

11.70 |

DXF | お問合せください |

お問合せください |

| WT2515-W1445-MF |

1445 |

50 |

13.6 |

12.43 |

DXF | お問合せください |

お問合せください |

| WT2515-W1530-MF |

1530 |

50 |

14.4 |

13.16 |

DXF | お問合せください |

お問合せください |

| WT2515-W1615-MF |

1615 |

50 |

15.2 |

13.89 |

DXF | お問合せください |

お問合せください |

| WT2515-W1700-MF |

1700 |

50 |

16.0 |

14.62 |

DXF | お問合せください |

お問合せください |

| WT2515-W1785-MF |

1785 |

50 |

16.9 |

15.36 |

DXF | お問合せください |

お問合せください |

| WT2515-W1870-MF |

1870 |

40 |

17.7 |

16.09 |

DXF | お問合せください |

お問合せください |

| WT2515-W1955-MF |

1955 |

お問合せください |

18.5 |

16.82 |

DXF | お問合せください |

お問合せください |

| WT2515-W2040-MF |

2040 |

お問合せください |

19.3 |

17.55 |

DXF | お問合せください |

お問合せください |

| WT2515-W2125-MF |

2125 |

お問合せください |

20.1 |

18.28 |

DXF | お問合せください |

お問合せください |

| WT2515-W2210-MF |

2210 |

お問合せください |

20.9 |

19.01 |

DXF | お問合せください |

お問合せください |

| WT2515-W2295-MF |

2295 |

お問合せください |

21.7 |

19.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W2380-MF |

2380 |

お問合せください |

22.5 |

20.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W2465-MF |

2465 |

お問合せください |

23.3 |

21.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W2550-MF |

2550 |

お問合せください |

24.1 |

21.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W2635-MF |

2635 |

お問合せください |

24.9 |

22.67 |

DXF | お問合せください |

お問合せください |

| WT2515-W2720-MF |

2720 |

お問合せください |

25.7 |

23.40 |

DXF | お問合せください |

お問合せください |

| WT2515-W2805-MF |

2805 |

お問合せください |

26.5 |

24.13 |

DXF | お問合せください |

お問合せください |

| WT2515-W2890-MF |

2890 |

お問合せください |

27.3 |

24.86 |

DXF | お問合せください |

お問合せください |

| WT2515-W2975-MF |

2975 |

お問合せください |

28.1 |

25.59 |

DXF | お問合せください |

お問合せください |

| WT2515-W3060-MF |

3060 |

お問合せください |

28.9 |

26.32 |

DXF | お問合せください |

お問合せください |

| WT2515-W3145-MF |

3145 |

お問合せください |

29.7 |

27.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W3230-MF |

3230 |

お問合せください |

30.5 |

27.78 |

DXF | お問合せください |

お問合せください |

|

耐紫外線  |

UVR |

ライトグレー |

△ |

12.8 |

8.6 |

50 |

50 |

-20~(60)80 |

特殊エンプラ |

ポリアセタール |

イエロー |

- |

|

| 形番 |

チェーン幅

X

mm |

1ユニットの

リンク数 |

最大許容張力

kN |

チェーン

質量

kg/m |

DXF

図形

データ |

標準価格/リンク |

納期 |

| WT2515-W85-UVR |

85 |

200 |

1.08 |

0.74 |

DXF | お問合せください |

お問合せください |

| WT2515-W170-UVR |

170 |

200 |

2.17 |

1.47 |

DXF | お問合せください |

お問合せください |

| WT2515-W255-UVR |

255 |

200 |

3.26 |

2.20 |

DXF | お問合せください |

お問合せください |

| WT2515-W340-UVR |

340 |

200 |

4.35 |

2.93 |

DXF | お問合せください |

お問合せください |

| WT2515-W425-UVR |

425 |

200 |

5.44 |

3.66 |

DXF | お問合せください |

お問合せください |

| WT2515-W510-UVR |

510 |

100 |

6.52 |

4.39 |

DXF | お問合せください |

お問合せください |

| WT2515-W595-UVR |

595 |

100 |

7.61 |

5.12 |

DXF | お問合せください |

お問合せください |

| WT2515-W680-UVR |

680 |

100 |

8.70 |

5.85 |

DXF | お問合せください |

お問合せください |

| WT2515-W765-UVR |

765 |

100 |

9.79 |

6.58 |

DXF | お問合せください |

お問合せください |

| WT2515-W850-UVR |

850 |

100 |

10.8 |

7.31 |

DXF | お問合せください |

お問合せください |

| WT2515-W935-UVR |

935 |

100 |

11.9 |

8.05 |

DXF | お問合せください |

お問合せください |

| WT2515-W1020-UVR |

1020 |

80 |

13.0 |

8.78 |

DXF | お問合せください |

お問合せください |

| WT2515-W1105-UVR |

1105 |

80 |

14.1 |

9.51 |

DXF | お問合せください |

お問合せください |

| WT2515-W1190-UVR |

1190 |

80 |

15.2 |

10.24 |

DXF | お問合せください |

お問合せください |

| WT2515-W1275-UVR |

1275 |

50 |

16.3 |

10.97 |

DXF | お問合せください |