ケーブルベヤ® プラシリーズ 3次元 TKRB形 主要諸元

TKRB21H10

構造

リンク

TKRB形(ロボトラックス)はリンク構造です。

リンク一端はボール形状、もう一端にはボールの受け皿となっており、リンク同士はスナップ連結されます。リンクに設定されたストッパーは3次元で最小屈曲半径を確保しています。リンク自身を回転させる動きも可能です。

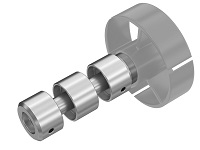

スチールワイヤーとシムボルト

ロボットのアームが素早く動くと、その際の加速度の影響でケーブルべヤには大きな張力が作用します。この張力に対応するために、リンク中央の孔にスチール製のワイヤーを通し、スチールワイヤーの両端にはシムを固定するボルトを取り付けています。

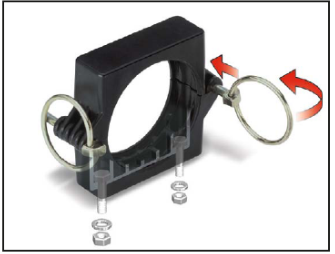

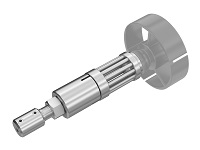

素早く開閉可能なブラケット

TKRB形(ロボトラックス)を(ロボットのアームなど)装置に取付けるためのブラケットは素早く容易に開閉でき、2本のボルトで装置に取付けられます。なお、ブラケットはどの位置のリンクにも取付けることができ、複雑な動きに対しても適します。

素早く開く構造

ピンを引き抜くとブラケットが開きます。

曲面に固定可能なブラケットホルダ

ブラケットを曲面のロボットアームに取り付けることが可能です。

ホースバンドにより容易に取り外しができます。

| ※ | CADデータはキャデナス・ウェブ・ツー・キャド(株)のCAD図面ライブラリーサイト「PARTcommunity」へのリンクにより提供いたします。 |

| ※ | CADデータ及びPARTcommunityのお問い合わせにつきましてはキャデナス・ウェブ・ツー・キャドまでご連絡ください。 【キャデナス・ウェブ・ツー・キャド株式会社】TEL: (03)5961‐5031 FAX: (03)5961‐5032 |

カタログ・取扱説明書

形番表示例

| TKRB | 21 | H10 | -10 | R70 | + | 50L | - | WB | - | CP | |

| | 品種記号 |

| ピッチ mm |

| 内高さ mm |

| 屈曲半径 mm |

| リンク数 L |

| 端末A |

| 端末B |

|||||

| * 端末A | ||

|---|---|---|

| WB | WBCL | SR |

| (ワイヤーボルト) | (クランプ付きワイヤーボルト) | (ロッキングボルト) |

|

|

|

| * 端末B | |

|---|---|

| CP | CPCL |

| (チャッキングパーツ) | (クランプ付チャッキングパーツ) |

|

|

注)

端末A・Bはそれぞれ記載の中からお選びください。記載以外はお問い合わせください。

なお端末A・Bは組み込んで納入します。

熱シールド/保護スリーブ

| TKRB21H10 | - | HS | + | 1.0M |

| | サイズ |

| HS:熱シールド DS:保護スリーブ |

| 長さ m |

||

注)

長さは小数点以下第1位までご指定が必要です。

1M(メートル)の場合でも1.0Mとご指定ください。

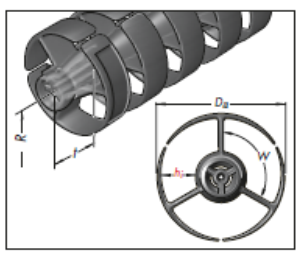

基本仕様

| サイズ | TKRB21H10 |

|---|---|

| 適合ケーブル・ホースの外径 mm | 2~8 |

| 屈曲半径 mm | 70 |

| 許容ねじり角度(1m当り) | ±450° |

| Da mm | 40 |

| hi mm | 10 |

| t(ピッチ) mm | 21.5 |

アクセサリ

プロテクタ

ロボットの動きに伴いTKRB形(ロボトラックス)本体が装置と接触する可能性があります。

プロテクタを用いれば、強い衝撃からTKRB形(ロボトラックス)本体を保護したり、屈曲半径を規制することが可能です。

ご注文はセット単位です(1セット=5個)。

| 形番 | 材質 | 質量 | 希望価格(税別) | 納期 | DXF図形・3DCADデータ |

|---|---|---|---|---|---|

| TKRB21H10-PT | エンプラ | お問合せください | ¥13,300 | お問合せください | DXF・3DCAD |

熱シールド/保護スリーブ

熱シールド:

アルミニウム被覆の繊維織物シールドはTKRB形(ロボトラックス)やケーブル類をスパッターから保護します。スパッターなどが飛散する使用環境に適します。(左図の上側)

保護スリーブ:

層状ポリエステル保護スリーブは降り掛かる切粉や切削油、粉塵、吹き付け塗料などから保護します。(左図の下側)

| 形番 | 材質 | 質量 | 希望価格(税別) /m |

納期 |

|---|---|---|---|---|

| TKRB21H10-HS (熱シールド) |

アラミド繊維 (アルミニウム被膜) |

お問合せください | ¥27,400 | お問合せください |

| TKRB21H10-DS (保護スリーブ) |

ポリエステル繊維 | お問合せください | ¥11,300 | お問合せください |

チャッキングパーツ

チャッキングパーツを用いれば素早く・容易にスチールワイヤーの張力を調整できます。再調整も容易です。

| 形番 | 材質 | 質量 | 希望価格(税別) | 納期 |

|---|---|---|---|---|

| お問合せください | スチール | お問合せください | お問合せください | お問合せください |

クランプ

結束バンドを用いてケーブルやホースを固定できます。

| 形番 | 材質 | 質量 | 希望価格(税別) | 納期 |

|---|---|---|---|---|

| お問合せください | スチール | お問合せください | お問合せください | お問合せください |

PBU(Pull Back Unit)

高速で広範囲にわたる動作を繰り返すロボットの動きに対し、長尺を要するTKRB形(ロボトラックス)本体とロボットとの接触を防止します。

| 形番 | 材質 | 質量 | 希望価格(税別) | 納期 |

|---|---|---|---|---|

| お問合せください | お問合せください | お問合せください | お問合せください | お問合せください |

ガイドホルダ

ケーブルベヤ本体と装置との接触を防止させ、システム故障を防止します。

・TKRB形はガイドホルダ内を移動します。取付けは簡単です。

・ケーブル類の挿入作業時等には素早く、容易に開閉できます。

| 形番 | 材質 | 質量 | 希望価格(税別) | 納期 | DXF図形・3DCADデータ |

|---|---|---|---|---|---|

| TKRB21H10-GH | エンプラ+スチール | お問合せください | ¥50,200 | お問合せください | DXF・3DCAD |

ブラケット

工具不要で開閉が容易なため、TKRB形を装置へ簡単に固定することができます。

TKRB形中間部の垂れを支持し、軌道の安定性を確保します。

旋回プレートやスプリング固定台と組み合わせて使用することで、より複雑な装置の軌道にも柔軟に対応します。

ブラケットと装置との固定には、ボルト呼び径M4の六角穴付ボルトをご使用ください。

注)納入時には装置へ固定するためのボルト用穴は貫通されていませんので、

貴社にてパンチなどを用いて貫通加工してください。

| 形番 | 材質 | 質量 | 希望価格(税別) | 納期 | DXF図形・3DCADデータ |

|---|---|---|---|---|---|

| TKRB21H10-QMB | エンプラ+スチール | お問合せください | ¥3,890 | お問合せください | DXF・3DCAD |

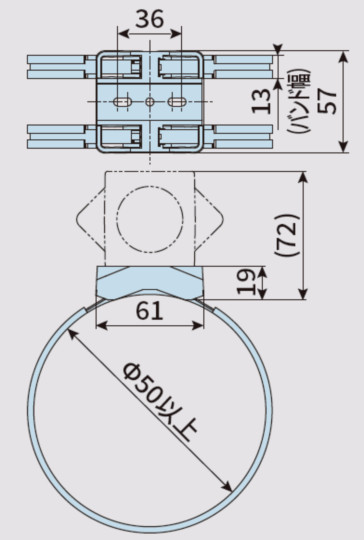

ブラケットホルダ

ホースバンドで曲面のロボットアームへも容易に取り付けることができます。

| 形番 | 取付可能 ロボットアーム直径 mm |

質量 g/個 |

希望価格 (税別) |

納期 | DXF図形 3DCADデータ |

|---|---|---|---|---|---|

| TKRB21H10-BH070 | Φ50~70 | 68 | ¥13,600 | お問合せください | DXF・3DCAD |

| TKRB21H10-BH090 | Φ50~90 | 76 | ¥16,700 | お問合せください | DXF・3DCAD |

| TKRB21H10-BH110 | Φ50~110 | 85 | ¥17,500 | お問合せください | DXF・3DCAD |

| TKRB21H10-BH130 | Φ50~130 | 94 | ¥22,100 | お問合せください | DXF・3DCAD |

| 材質 | ||

|---|---|---|

| 本体 | ホースバンド | バンドカバー |

| エンプラ | ステンレス ボルト:スチール(亜鉛メッキ) |

合成ゴム |

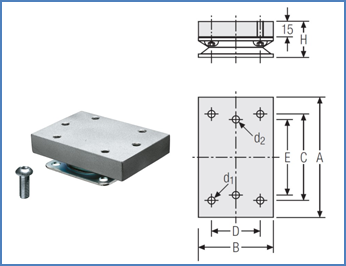

旋回プレート

ベアリングを内蔵しており、スムーズに旋回します。

ブラケットの旋回可動を実現し、より複雑な装置の軌道にも柔軟に対応します。

| 形番 | A | B | C | D | E | H | d1 | d2 |

|---|---|---|---|---|---|---|---|---|

| TKRB21H10-TH (ブラケット取付用) |

57 | 57 | 43 | 43 | 36 | 27.5 | M6 | M4 |

| TKRB40H22-TH (ガイドホルダ取付用) |

82 | 57 | 43 | 43 | 64 | 27.5 | M6 | M6 |

※専用ボルト4個付属

| 形番 | 材質 | 質量 | 希望価格(税別) | 納期 | DXF図形・3DCADデータ | |

|---|---|---|---|---|---|---|

| ブラケット 取付用 |

TKRB21H10-TH | スチール+アルミ | お問合せください | ¥23,700 | お問合せください | DXF・3DCAD |

| ガイドホルダ 取付用 |

TKRB40H22-TH | スチール+アルミ | お問合せください | ¥25,700 | お問合せください | DXF・3DCAD |

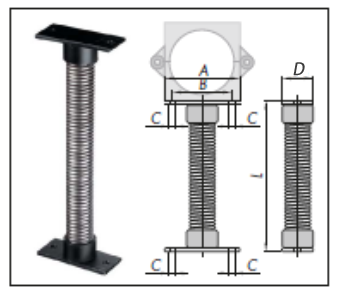

スプリング固定台

ばね構造を利用してブラケットの3次元的な動きを実現します。

動作が終わると元の状態に戻ります。装置とTKRB形の間のスペース確保も可能です。

注)TKRB40H31のスプリング固定台はブラケット取付用のみとなります。

| 形番 | A | B | C | D |

|---|---|---|---|---|

| TKRB21H10-FHL□□□ (ブラケット取付用) |

52 | 36 | 5 | 26 |

| TKRB40H22-FHL□□□ (ガイドホルダ取付用) |

82 | 64 | 6.5 | 34 |

| 形番 | 材質 | 質量 | 希望価格(税別) | 納期 | DXF図形・3DCADデータ | |

|---|---|---|---|---|---|---|

| ブラケット 取付用 |

TKRB21H10-FHL110 | スチール | お問合せください | ¥41,300 | お問合せください | DXF・3DCAD |

| TKRB21H10-FHL150 | スチール | お問合せください | ¥41,700 | お問合せください | ||

| ガイドホルダ 取付用 |

TKRB40H22-FHL165 | スチール | お問合せください | ¥47,800 | お問合せください | DXF・3DCAD |

| TKRB40H22-FHL230 | スチール | お問合せください | ¥48,700 | お問合せください | ||

| TKRB40H22-FHL315 | スチール | お問合せください | ¥50,000 | お問合せください | ||

| TKRB40H22-FHL465 | スチール | お問合せください | ¥51,700 | お問合せください |

ホームページからのお問い合わせ/資料請求

製品お問い合わせ

各製品へのお問い合わせ及び製品カタログ・資料請求はこちらより承っております。

ご利用の際は当サイトの会員登録をお願いします。

【お問い合わせ】 |

【資料請求】 |

|---|

本製品を日本国外で購入される場合には、下記リンクにある最寄りの海外拠点までお問い合わせください。

各種証明書の発行について

一部の証明書は弊社製造番号と紐づけて発行しております。

以下についてはご購入先を通じてご依頼ください。

・該非判定書

・EAR判定書

・原産地証明書

見積依頼、納期確認について

弊社では直接販売をしておりません。

購入価格・納期に関するお問い合わせはお取引のある商社様を通じてご確認ください。

購入先をお探しのお客様は取扱販売店一覧をご覧ください。

お問い合わせ窓口

製品窓口

| ケーブルベヤ | TEL : 0120-251-664 | FAX : 0120-251-665 |

|---|

月曜日~金曜日 9:00~12:00 / 13:00~17:00

(祝日・弊社休業日を除く)